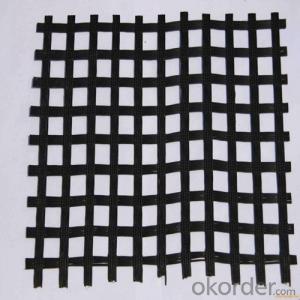

High flexibility Fiberglass Polypropylene Geogrid Roadbed Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

Model Number:

20KN/M--50KN/M

Material:

Plastic

width:

1-6m

Certificate:

CE,ISO

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

fiberglass geogrid/glass fiber geogrid with CE certificate Introduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile effect

- First, the drainage effect: polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. Second, the role of contraction: When the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand , Small stone, etc., in order to maintain the stability of soil and water engineering. Third, the isolation role: the use of polyester staple acupuncture geotextile with different physical properties of the building materials to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Fourth, the role of puncture: and geomembrane combined into a composite waterproof impermeable material, play the role of anti-puncture. High tensile strength, good permeability, breathable properties, high temperature resistance, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten. Polyester staple acupuncture geotextile is a widely used geosynthetics.

- Q:Are geotextiles suitable for use in high-temperature environments?

- Yes, geotextiles are suitable for use in high-temperature environments. Geotextiles are designed to withstand a wide range of temperatures, including high temperatures. They are often used in applications such as road construction, erosion control, and drainage systems in hot climates without any issues.

- Q:Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are permeable fabrics that can provide reinforcement and stabilization to the soil behind the retaining wall. They can help prevent erosion, reduce water pressure, and improve the overall stability and longevity of the retaining wall.

- Q:What are the different methods of installing geotextiles?

- There are several different methods of installing geotextiles, including direct placement, trenching, and stapling. Direct placement involves unrolling the geotextile fabric directly onto the ground surface and securing it with stakes or pins. Trenching involves digging a narrow trench along the desired location and placing the geotextile fabric inside the trench before backfilling it. Stapling involves using staples or nails to secure the geotextile fabric to the ground or other surfaces. The specific method used depends on the project requirements and the intended function of the geotextiles.

- Q:Seepage geotextile symbol

- At present, the engineering commonly used seepage geotextile is divided into polyester staple geotextile and polyester filament geotextile two. Polyester staple geotextile identification symbol for the SNG, for example, 150g / ㎡ polyester staple geotextile can be expressed as SNG150. Polyester filament geotextile identification symbol for the FNG, for example, 200g / ㎡ of polyester filament geotextile can be expressed as FNG200. In the national standard in the seepage geotextile on the permeability of the test items are equivalent pore size O90 (95) / mm and vertical permeability coefficient CM / S two.

- Q:Can geotextiles be used in the construction of golf course bunkers?

- Yes, geotextiles can be used in the construction of golf course bunkers. Geotextiles are commonly used in construction projects to stabilize and reinforce soil. In the case of golf course bunkers, geotextiles can be used to prevent erosion, improve drainage, and provide a stable base for the sand.

- Q:What are the different geotextile durability testing standards?

- There are several geotextile durability testing standards, including the ASTM D4355-17 for durability of geotextiles by accelerated weathering exposure, ASTM D4751-10 for determining the apparent opening size of a geotextile, ASTM D6768-18 for evaluating the effects of heat on geotextiles, and ISO 10319:2015 for determining the resistance of geotextiles to weathering.

- Q:What are the durability considerations for geotextiles?

- Durability considerations for geotextiles include factors such as UV degradation, chemical resistance, mechanical strength, and resistance to punctures and abrasions. Geotextiles should be designed to withstand harsh environmental conditions and maintain their functionality over an extended period of time.

- Q:Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are commonly employed as a liner or cover material to enhance the stability, drainage, and filtration properties of the landfill. Geotextiles help to prevent the mixing of different waste materials, control erosion, and promote proper drainage of leachate.

- Q:What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on several factors. Initially, geotextiles may have a higher upfront cost compared to traditional materials. However, they can provide long-term cost savings by extending the lifespan of infrastructure and reducing maintenance requirements. Geotextiles can also minimize the need for expensive excavation and replacement of poor soil, resulting in overall cost reductions. Additionally, the use of geotextiles can enhance construction efficiency, reducing labor costs and project timelines. Therefore, while there may be initial investment, the long-term cost implications of using geotextiles can be beneficial.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High flexibility Fiberglass Polypropylene Geogrid Roadbed Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords