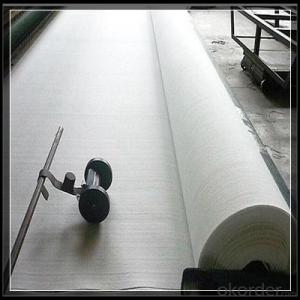

Warp Glass Fiber Composite Geotextiles for Real Estate from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Warp knitted compound, that is bound by line by the warp, weft and acupuncture staple fiber geotextile layer repeatedly walk through, so that became one of the three series. Thus both the warp composite geotextiles with high tensile strength, low elongation characteristics, and both the performance of acupuncture nonwovens. Therefore, Warp is a composite geotextile reinforcement can be used for enhanced isolation protection, and has a three-dimensional integral method to gather and have good water levels, different role of water. Showed a solid matrix and pores because of its continuous phase, a porous filter effect, is a versatile geotextile composites. It is today a high level of application of the international geotechnical composite substrate.

Features:

High tensile strength, low elongation, vertical and horizontal deformation of the uniform, tear strength, excellent wear resistance, high permeability, filter and strong.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How do geotextiles help with weed control in landscaping projects?

- Geotextiles aid in weed control in landscaping projects by acting as a barrier between the soil and the weed seeds. These permeable fabrics allow water and air to pass through, ensuring proper drainage and maintaining soil health, while preventing weed growth by blocking sunlight and impeding weed seed germination.

- Q:What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific material and application. In general, higher temperatures can cause geotextiles to expand and become less stable, while lower temperatures can make them more rigid and prone to cracking. Extreme temperature fluctuations can also affect the long-term durability and effectiveness of geotextiles. Therefore, it is crucial to consider temperature conditions when selecting and designing geotextile applications to ensure optimal performance and longevity.

- Q:Can geotextiles be used for filtration purposes?

- Yes, geotextiles can be used for filtration purposes. They are designed to allow water or other liquids to pass through while retaining soil or other particles, making them effective for various filtration applications in areas such as agriculture, construction, and environmental engineering.

- Q:Roof of the geotextile

- Garage, roof green Huazhi geotextile manufacturers, solutions

- Q:What are the different manufacturing methods for geotextiles?

- There are several different manufacturing methods for geotextiles, including weaving, knitting, and nonwoven processes. Weaving involves interlacing two sets of yarns, warp, and weft, to create a fabric with an ordered structure. Knitting, on the other hand, uses a series of interconnected loops to form a fabric. Nonwoven processes involve bonding fibers together through methods such as needle punching, thermal bonding, or chemical bonding. Each method has its own advantages and is used depending on the specific requirements of the geotextile application.

- Q:What are the different geotextile reinforcement techniques?

- There are several different geotextile reinforcement techniques, including mechanical methods such as soil nails, ground anchors, and geogrids, as well as chemical methods like soil stabilization using polymers or cement additives. Additionally, techniques such as soil wrapping, slope terracing, and retaining walls can also be used to provide geotextile reinforcement in various applications.

- Q:How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q:What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have a wide range of applications in geotechnical engineering. They are commonly used for soil stabilization, erosion control, and drainage systems. Geotextiles can be used to reinforce soil, preventing slope failures and improving the stability of embankments and retaining walls. They also serve as a barrier against soil erosion by maintaining the integrity of the soil structure. In addition, geotextiles are used for filtration and separation purposes, allowing water to pass through while preventing the movement of fine particles. Overall, geotextiles play a crucial role in enhancing the performance and longevity of various geotechnical structures.

- Q:1 square of non-woven geotextiles how many tons

- Do you ask how many grams / square of non-woven geotextiles how much a ton? At present, the price of geotextile is subject to fluctuations in the impact of raw materials, the specific price needs to be priced seven days before the purchase. Geotextile manufacturers in the Swiss Zhang Ming Chao answer for you.

- Q:What are the quality control measures for geotextile manufacturing?

- Some quality control measures for geotextile manufacturing include thorough testing of raw materials, regular inspections of production processes, and adherence to industry standards and specifications. Additionally, ensuring proper calibration and maintenance of manufacturing equipment, conducting quality checks at various stages of production, and implementing robust quality management systems are essential for maintaining the desired quality and performance of geotextile products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Warp Glass Fiber Composite Geotextiles for Real Estate from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords