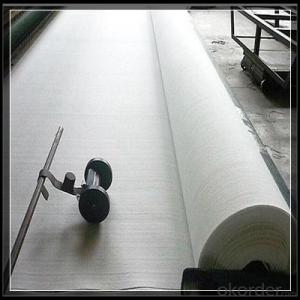

Non-Woven Geotextile Industrial Nonwoven fabric with Highest Quality High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

Non-woven geotextiles are ideal for use in foundation drainage, behind retaining walls and gabions, in sub-drains, and under rip-rap & armourstone.

Most environmental codes and regulations will require geosynthetic linings for landfill and waste management projects.

Our non-woven geotextile fabrics contain high-grade polypropylene fibres to provide physical strength and excellent fluid management properties.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What is geotextile? Its use

- The role of geotextile filter When the water from the fine soil into the coarse soil layer, the use of acupuncture geotextile good permeability and water permeability, so that water flow, and effectively cut off soil particles, spun yarn, small Stone, etc., in order to maintain the stability of soil and water engineering. The role of geotextile drainage Geotextile is a good water guide material, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas outside. The role of geotextile reinforcement using geotextile to enhance the soil tensile strength and resistance to increase the stability of the building structure to improve the quality of soil. The role of geotextile protection effectively spread the concentration of stress, transmission or decomposition, to prevent the soil by external forces and damage.

- Q:How do geotextiles help with erosion control on shorelines?

- Geotextiles help with erosion control on shorelines by acting as a barrier that prevents soil erosion while still allowing water to pass through. They stabilize the soil by trapping sediment and preventing it from being washed away by waves or currents. Additionally, geotextiles promote the growth of vegetation, which further helps to anchor the soil and reduce erosion.

- Q:Are geotextiles resistant to extreme weather conditions?

- Yes, geotextiles are designed to be resistant to extreme weather conditions. They are typically made from durable materials that can withstand heavy rainfall, high winds, and temperature variations. Geotextiles are commonly used in construction and civil engineering projects to provide stability and erosion control in challenging environments.

- Q:Geotextile between the use of lap, lap width is not less than?

- 1.5 m

- Q:What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the material composition, thickness, and density of the geotextile, as well as the shape, size, and velocity of the puncturing object. Other factors such as the installation method, environmental conditions, and the presence of any protective layers also play a role in determining the puncture resistance of geotextiles.

- Q:Geotextile strength index with interpolation method how to calculate? Then geotextile variation, I do not quite understand, pro, if you know whether to tell me Oh! Very anxious

- Geotextile strong indicators of the interpolation method: For example: geotextile 150 grams of breaking strength is 4.5KN, geotextile 100 grams of breaking strength is 2.5KN, then the geotextile 130 grams of broken strength is how much? The calculation method is: 4.5KN-2.5KN = 2KN (that is, 50 grams of geotextile strength) 2KN by 50 grams multiplied by 30 grams is equal to 1.2KN then geotextile 130 grams of breaking strength is 3.7KN.

- Q:Geotextile universal testing machine with 20kn enough?

- Enough, we use is 20kn

- Q:How do geotextiles improve the performance of pavement structures?

- Geotextiles improve the performance of pavement structures by enhancing their strength, stability, and durability. They act as a separator between the subgrade and the pavement layers, preventing mixing and intermixing of these materials. Geotextiles also help in distributing the load from traffic more uniformly, reducing stress and potential damage to the pavement. They can also act as a filter, preventing the migration of fine particles from the subgrade into the pavement layers, which can further destabilize the structure. Overall, geotextiles enhance the longevity and functionality of pavement structures.

- Q:Can geotextiles be used in groundwater protection systems?

- Yes, geotextiles can be used in groundwater protection systems. Geotextiles are permeable fabrics that allow water to pass through while filtering out contaminants. They can be used as a protective barrier to prevent the migration of pollutants into groundwater sources, acting as a physical barrier and filtration system.

- Q:Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are generally designed to be resistant to punctures and tears. They are made from strong materials that provide durability and can withstand external forces, making them an effective solution for various applications requiring such resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-Woven Geotextile Industrial Nonwoven fabric with Highest Quality High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords