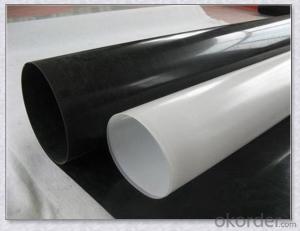

Waterproof Geomembrane 2 Mm Hdpe Geomembrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Geomembrane

Composite Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance. Is a kind of polymer chemistry flexible material, the proportion of small, extensible stronger ability to adapt to high deformation. Corrosion resistance, low temperature, frost good performance. Have better resistance to erosion, are not afraid of acid, alkali and salt erosion.

Specifications

professional,satisfied service , the most competitive price , the best product ,do as your requirement

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q:What kind of geotextiles are used in highway geotextiles?

- Highway geotextile is a new type of civil artifacts material, for the construction of geotextile highway can also be Hongxiang filament geotextile, not only need to resist the complex stress under the comprehensive mechanical properties of tensile properties, etc. But also to ensure that a variety of natural factors under the influence of a long time, the overall performance does not produce significant attenuation, that is, long-term stability, high and low temperature performance, anti-aging properties. Hongxiang filament geotextile can improve the carrying capacity of the road, can improve the road in the process of using the structure of the destruction of the problem

- Q:How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and uniform platform for distributing the load from the structure to the underlying soil. They act as a separator, preventing the mixing of different soil layers and reducing the risk of differential settlement. The geotextiles also enhance the soil's strength and stability, thereby improving the overall load-bearing capacity of the foundation system.

- Q:Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a protective barrier or separator in geosynthetic clay liner systems to enhance their performance and prevent clogging or migration of fine particles.

- Q:How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests that evaluate their physical, mechanical, and hydraulic properties. These tests may include assessing tensile strength, elongation, puncture resistance, water permeability, and filtration efficiency, among others. By conducting these tests, manufacturers can ensure that geotextiles meet the required performance specifications and provide consistent quality for various civil engineering applications.

- Q:How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing reinforcement and filtration. They act as a barrier to prevent the loss of soil particles while allowing water to pass through, thereby enhancing the stability and strength of geotubes. Additionally, geotextiles help distribute loads evenly, reducing the risk of erosion and increasing the overall performance and longevity of geotubes.

- Q:The outside of the blind tube is not to be with the geotextile 1 effect will be better?

- Plastic blind ditch is a new geosynthetics, is composed of plastic core wrapped outside the filter composition. At present the plastic core has several different cross-sectional shape rectangular, hollow rectangular, circular and hollow circular species structure of the plastic blind ditch products. Pass the water to see the original tie & gt; & gt;

- Q:River slope protection geotextile unit area quality is generally how much

- Under normal circumstances is 100g - 1000g / square meter of the specifications, the actual situation is subject to special requirements, usually available geotextile unit area quality tester for testing, reference [standard group]. Test criteria: ASTM / D3776 / 2646, ISO3801, BS3424 / 2471, BSEN, M + SP65 / 65A, NEXT20

- Q:Construction Technology of Seepage Control of Geotextile for Landscape Water System

- Laying HDPE geomembrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. Geomembrane thickness of not less than 0.25mm, too thin may produce pores, and easy to damage in the construction and reduce the anti-seepage effect. Geomembrane construction, in particular, should pay attention to laying should not be too tight, not wrinkled, stitching to be strong. Should be strictly in accordance with technical specifications construction, the good preparation, laying, splicing, inspection and backfill, such as five quality off. I specialize in production and construction

- Q:What are the uses of acupuncture geotextiles?

- I specialize in producing geotextile materials

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Geomembrane 2 Mm Hdpe Geomembrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords