Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and

specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon,

with excellent corrosion and heat resistance performance.

Strong, yet lightweight, Galvalume wont crack or peel when subjected to weather. Galvalume consists

of 55% aluminum, 43.4% zinc and 1.6% silicon over the base metal. This coating is applied during

a continuous hot-dip process. AZ40, AZ50, AZ55 and AZ60 translate to the coating thickness of .40,

.50, .55 and .60 ounces per square foot, respectively.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

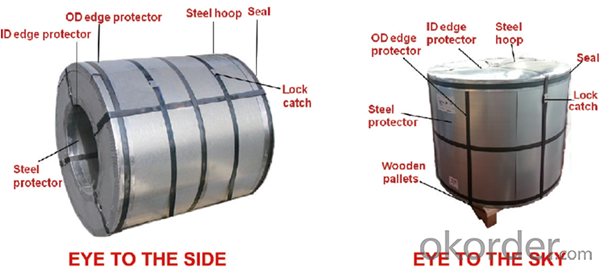

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q:What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including galvanizing, painting, powder coating, and zinc coating. These treatments help protect the steel from corrosion and improve its durability and appearance.

- Q:I just purchased this Benchmade knife with m390 steel blade and it cost me a fortune but I wanted to know if this new steel is a tool steel. what classifies a tool steel. M390 = 1.9 carbon, 20. chromium, .30 manganese, 1. molybdenum, .60silicon, .60 tugsten, 4. vanadium at 60-62 HRC

- Which has better songs - Number Of the Beast Which has better riffs - British Steel Which has better solos - Number of The Beast Which has better vocals - Number of the Beast Which has a cooler cover - Number of the Beast Which do You prefer - This is a real thinker, almost like Sophies Choice Metal edition. But I have owned Number and the Beast longer than I have owned British Steel. So I go with Iron Maiden Both albums get a perfect 10 because they deserve it, both have great musicianship and both have great vocals

- Q:What are the different types of steel coil cutting blades?

- Various types of steel coil cutting blades exist, each specifically designed for particular cutting purposes. 1. Slitting Blades: These blades are utilized to cut steel coils into narrow strips. They possess a straight cutting edge and come in different widths to accommodate various slitting needs. Industries like automotive, construction, and metal fabrication commonly employ these blades. 2. Shearing Blades: These blades are created to cut steel coils into flat sheets. They feature a curved cutting edge that enables a clean and precise cut. Steel service centers, where large coils are transformed into flat sheets for further manufacturing processes, frequently utilize shearing blades. 3. Circular Blades: Also known as rotary blades, these blades are employed for continuous cutting of steel coils. With a circular shape adorned with sharp teeth along the edge, they can effectively cut through the coil as it passes through the cutting machine. Industries such as packaging, printing, and paper manufacturing often make use of circular blades. 4. Guillotine Blades: These blades are employed to cut steel coils in a straight downward motion. Possessing a vertically moving straight cutting edge, they can effectively slice through the coil. Guillotine blades are frequently used in heavy-duty cutting applications that involve thick steel coils or large quantities of material. 5. Slitter Knives: Similar to slitting blades, slitter knives are typically smaller and employed in slitting machines that require multiple blades. Industries requiring high-precision slitting, such as electrical transformer production or precision metal stamping, often rely on slitter knives. Each type of steel coil cutting blade possesses unique characteristics and designs that render them suitable for specific cutting tasks. The appropriate blade selection depends on factors like steel coil thickness and width, desired cut quality, and specific application requirements.

- Q:What are the factors affecting the strength of steel coils?

- There are several factors that can affect the strength of steel coils. 1. Steel Grade: The type and quality of the steel used in the coils plays a significant role in determining their strength. Different steel grades have varying levels of carbon content, alloying elements, and heat treatment processes, which can impact the overall strength and durability of the coils. 2. Manufacturing Process: The way in which the steel coils are manufactured can also affect their strength. Factors such as the temperature and duration of the heat treatment, the rolling and annealing processes, and the level of cold working can all influence the final strength of the coils. 3. Thickness and Width: The thickness and width of the steel coils can affect their strength. Thicker coils tend to be stronger and more resistant to deformation, while wider coils may exhibit variations in strength across their surface. 4. Surface Quality: The condition of the coil's surface, including any imperfections or defects, can influence its strength. Surface defects such as scratches, pits, or corrosion can act as stress concentration points, reducing the overall strength of the coil. 5. Storage and Handling: The way in which the coils are stored and handled can impact their strength. Factors such as exposure to moisture, extreme temperatures, or improper stacking and transportation can lead to deformation or damage, decreasing the strength of the coils. 6. Environmental Conditions: Environmental factors such as humidity, temperature, and exposure to corrosive agents can also affect the strength of steel coils. In harsh environments, the coils may experience accelerated corrosion, leading to a decrease in their strength over time. It is important to consider these factors when selecting and utilizing steel coils to ensure that they meet the required strength specifications for the intended application.

- Q:i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- Basically all the others are right, except Skeptical who never answered your question. Just thru out an insult....what was that you said about growing up?...hmmmmm Also Skeptical...take a look at modern day guns (pistols and rifles), holsters, knives, even bullet, packaging and boxes for the above. You don't think looks play a role in design? Aesthetics and whether something is pleasing to the eye ALWAYS plays a role in marketing. To answer the question though, it allows the shell expansion to seal the chamber, it's lighter, and also much easier and prolongs the life of the extractor.

- Q:How do steel coils compare to other materials in terms of cost?

- Compared to other materials, steel coils offer greater cost-effectiveness. This is due to the fact that steel is widely accessible and abundant, leading to relatively low production costs. Moreover, steel coils boast an extended lifespan and require minimal upkeep, resulting in reduced expenses over time. The exceptional durability and strength of steel also make it an optimal selection for a wide range of applications, further augmenting its cost-effectiveness. When contrasted with materials such as aluminum or copper, steel coils are typically more economical, making them the preferred option for numerous industries.

- Q:What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the manufacturing process, transportation limitations, and storage capabilities. However, it is common for steel coils to have a maximum length of around 30 meters (100 feet) or even longer in some cases.

- Q:Okay, I have looked all ovcer the net and it says diamonds are stronger, but why? I mean, why is diamonds used for the top equiptment rather than steel?

- Diamonds okorder

- Q:How are steel coils inspected for surface finish?

- Steel coils are typically inspected for surface finish using visual inspection techniques and specialized equipment such as surface roughness testers, gloss meters, and profile scanners. These methods help to assess the coil's smoothness, texture, and appearance, ensuring it meets the required surface finish specifications.

- Q:What are the different types of coil edge trimming machines?

- There are several types of coil edge trimming machines available in the market. Some common types include manual coil edge trimmers, pneumatic coil edge trimmers, and automatic coil edge trimmers. Manual coil edge trimmers require manual operation and are suitable for low volume production. Pneumatic coil edge trimmers use compressed air to power the trimming process, making them faster and more efficient. Automatic coil edge trimmers are fully automated machines that can handle high volume production, enhancing productivity and reducing labor requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords