Polyester Geotextile Fabric High-Performance for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Geotextile Functions

Separation

CNBM Geotextile acts as a separator between two layers of soil that have different

particle size distributions. CNBM Geotextiles are used to prevent road base materials from

penetrating into soft underlying sub grade soils, thus maintaining design thickness and

roadway integrity. Separators also help to prevent fine-grained sub grade soils from being

pumped into permeable granular road bases.

separation

Filtration

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

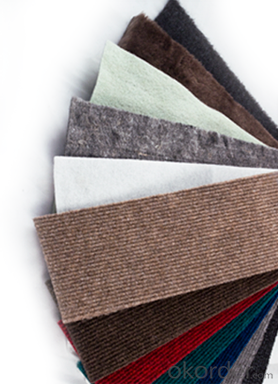

A: Yes, please check the pictures:

- Q:How do geotextiles help in the prevention of clogging in drainage systems?

- Geotextiles help prevent clogging in drainage systems by acting as a filter barrier, allowing water to pass through while trapping and preventing the migration of fine particles or soil into the drainage system. This helps maintain the long-term functionality and efficiency of the drainage system by reducing the risk of clogging or blockages.

- Q:Geotextile what is the law?

- Geotextiles, engineering cloth, impermeable cloth, non-woven fabrics, polyester cloth, health cloth, permeable cloth, etc., which are based on the use of different materials or different materials. But in fact are geotextiles. Geotextile types are many: woven geotextile, staple acupuncture geotextile, filament geotextile, impervious geotextile, non-woven geotextile, composite geotextile, warp-resistant geotextile

- Q:How are geotextiles used in retaining walls?

- Geotextiles are commonly used in retaining walls to provide reinforcement and stability to the structure. They are placed between the soil and the retaining wall to act as a barrier, preventing soil erosion and promoting better drainage. Additionally, geotextiles help to distribute the load evenly across the wall, reducing the risk of wall failure.

- Q:What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. Firstly, the application or purpose of the geotextile is important. Different geotextiles are designed for specific functions such as filtration, separation, drainage, or reinforcement. Understanding the specific requirements of the project and matching them with the appropriate geotextile is crucial. Secondly, the site conditions need to be evaluated. Factors such as soil type, slope stability, groundwater levels, and expected loads or stresses should be considered. The geotextile should be able to withstand these conditions and provide the necessary performance. Thirdly, the durability and longevity of the geotextile should be assessed. Factors like UV resistance, resistance to chemicals or biological degradation, and the expected lifespan should be evaluated to ensure that the selected geotextile can withstand the anticipated environmental conditions. Additionally, the installation and maintenance requirements should be taken into account. Some geotextiles may require specialized equipment or techniques for installation, while others may need periodic monitoring or maintenance. Understanding these requirements is essential for a successful project. Lastly, cost-effectiveness is an important factor. While it is crucial to select a geotextile that meets the project requirements, it is also necessary to consider the associated costs. Evaluating the initial cost, as well as the long-term benefits and potential savings, helps in making an informed decision. In summary, the factors to consider when selecting a geotextile include the specific application, site conditions, durability, installation requirements, and cost-effectiveness.

- Q:what is the purpose of geotextile on gabion walls.?

- Geotextiles are fabrics associated with soil, earth or rocks. Gabions were earth filled barricades meant to halt enemy fire during battle. I'm guessing geotextiles on gabion walls more effectively hold back the earth or filler. They might have well suited permeability or retentive qualities for gabions. There are a few other definitions for gabions. But this is the militaristic definition. Gabions are also used in dams and such. In this case, geotxtiles might have good properties for being submerged in water and still retaining whats inside the gabions.

- Q:Are geotextiles suitable for use in canal lining?

- Yes, geotextiles are suitable for use in canal lining. They provide effective erosion control and filtration, preventing soil loss and allowing water to flow through while retaining fines. Geotextiles also offer durability, resistance to UV degradation, and can be installed easily.

- Q:Roof 1: 3 cement mortar leveling layer mixed with polypropylene or nylon-6 fiber is the role of what?

- Compensation shrinkage, to prevent cracking, from a certain degree of tensile effect

- Q:How are geotextiles tested for permeability?

- Geotextiles are tested for permeability using various standardized methods such as the constant head method, falling head method, and the flexible wall permeameter. These tests involve measuring the flow of water through the geotextile under controlled conditions to determine its permeability characteristics.

- Q:How do geotextiles help in preventing soil contamination?

- Geotextiles help in preventing soil contamination by acting as a barrier between the soil and potential contaminants. They are permeable fabrics that allow water and air to pass through while filtering out harmful substances. Geotextiles can be used to line landfills, ponds, and other containment areas to prevent the leaching of pollutants into the soil. They can also be used in erosion control measures to stabilize soil and prevent the spread of contaminants.

- Q:Are geotextiles suitable for use in landfill caps?

- Yes, geotextiles are suitable for use in landfill caps. They are commonly used as a component of landfill cap systems due to their ability to provide separation, filtration, and drainage functions. Geotextiles help to prevent the mixing of different materials, such as soil and waste, while allowing for water drainage and filtration. This helps to enhance the stability, longevity, and environmental performance of landfill caps.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Geotextile Fabric High-Performance for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords