Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

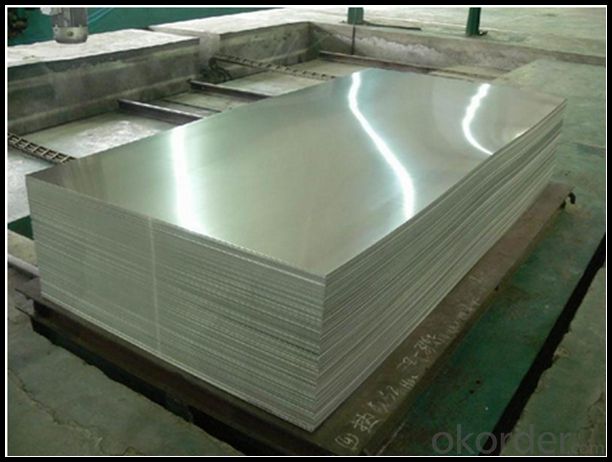

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

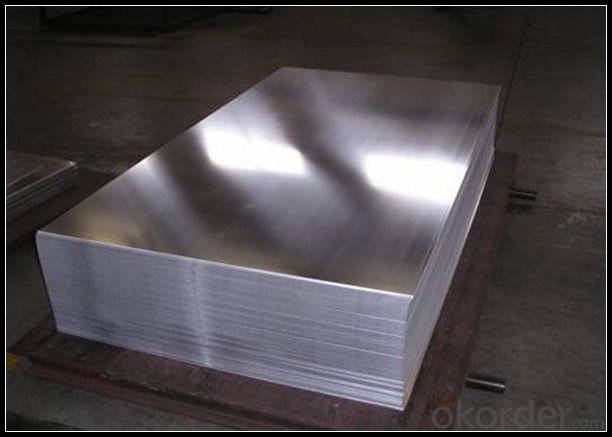

5. Image of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- Chaoyang aluminum manufacturers tell you that you can ask the manufacturer to cover the aluminum plate surface, to prevent aluminum plate scraping it!

- Q:Can aluminum sheet be used in marine environments?

- Certainly, aluminum sheet finds utility in marine environments. The corrosion resistance exhibited by aluminum renders it a favored material for marine purposes. The formation of a safeguarding oxide layer on its exterior effectively curbs corrosion, even in the presence of saltwater. Moreover, aluminum's lightweight nature qualifies it as an optimal selection for marine applications where weight reduction is paramount. Given its robustness, strength, and corrosion resistance, aluminum sheet is extensively employed in boat hulls, decks, and various other marine constructions.

- Q:what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q:What are the different methods of surface laminating aluminum sheets?

- There are several methods of surface laminating aluminum sheets, including adhesive bonding, roll bonding, and extrusion. Adhesive bonding involves using an adhesive to attach a layer of material onto the surface of the aluminum sheet. Roll bonding involves passing the aluminum sheet through a set of rollers, which bond a layer of material onto the surface. Extrusion involves forcing the aluminum sheet through a die, which applies a layer of material onto the surface. These methods provide different options for achieving surface lamination based on the desired application and requirements.

- Q:Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as column covers. It can be easily shaped, bent, and fabricated to create custom designs and sizes, allowing for versatility in architectural projects. Additionally, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their aesthetic appeal and provide additional protection against weathering and wear. Overall, aluminum sheets provide a great combination of strength, versatility, and aesthetics, making them a suitable choice for manufacturing architectural column covers.

- Q:Can aluminum sheet be used for cookware?

- Yes, aluminum sheet can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight properties. However, it is usually combined with other materials, such as stainless steel or non-stick coatings, to enhance its durability and prevent any potential reactions with certain foods.

- Q:What are the different bending techniques for aluminum sheets?

- There are several bending techniques that can be used for aluminum sheets. Some of the most commonly used techniques include: 1. Air bending: In this technique, a punch is used to apply force on the sheet, which causes it to bend along a straight line. The bend angle is determined by the amount of force applied. 2. Bottom bending: This technique involves clamping the sheet between a bottom tool and a die, while a punch is used to apply force on the sheet from the top. The sheet is bent around the die, resulting in a precise and consistent bend angle. 3. Coining: Coining is a technique in which the sheet is bent using a punch and a die, but with significantly higher force applied compared to other bending techniques. This creates a crisp and sharp bend with minimal springback. 4. Rotary bending: In rotary bending, the sheet is bent around a rotating bending roll. The roll exerts pressure on the sheet, causing it to bend gradually and smoothly. 5. Roll bending: This technique involves passing the aluminum sheet through a series of rollers, which gradually bend the sheet to the desired shape. It is often used for bending large sheets or for creating cylindrical shapes. 6. Press braking: Press braking is a versatile technique that uses a press brake machine to bend the sheet. The machine consists of a punch, a die, and a back gauge, which allows for precise and repeatable bends. Each bending technique has its own advantages and limitations, and the choice of technique depends on factors such as the desired bend angle, the thickness of the sheet, and the overall shape of the final product. It is important to carefully select the appropriate bending technique to ensure the desired result and avoid any defects or damage to the aluminum sheet.

- Q:How do aluminum sheets perform in terms of heat reflectivity?

- Aluminum sheets are highly efficient in terms of heat reflectivity. Due to their high reflectivity, they are able to effectively reflect heat and light away from the surface, thereby minimizing heat absorption. This property makes aluminum sheets an ideal choice for applications where heat management is crucial, such as in roofing, insulation, and solar panels. The reflective nature of aluminum sheets helps to reduce energy consumption by preventing excessive heat buildup, resulting in a cooler environment. Additionally, aluminum's reflectivity also contributes to its use in various industrial and scientific applications, such as in the manufacturing of reflectors, heat sinks, and optical mirrors.

- Q:General characteristics of pure aluminium plate of pure aluminium plate

- Comparison of pure aluminium sheets:1, grade: 1A85, 1A90, 1A93, 1A97, 1A99;Product type: plates, belts, foils, tubes;Main characteristics: Industrial high-purity aluminum;Applications: mainly used in the production of various electrolytic capacitor foil, acid fast container, etc., products have plates, belts, foils and so on.2, grade: 1060, 1050A, 1035;Product type: foil, wire;Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but the strength is low, it can not be strengthened by heat treatment, cutting is not good. Acceptable contact welding and gas welding;Scope of application: use the advantages of making some structures with specific properties, such as aluminum foil gasket and capacitor, electronic tube isolation network, wire and cable protective sleeve, net, wire core and aircraft parts and trim ventilation system.3, brand: 1100;Product type: Sheet & strip;Main features: for ordinary industrial pure aluminum aluminum content of 99%, can not be strengthened by heat treatment; low strength, but has good ductility, formability, weldability and corrosion resistance; anodic oxidation can improve corrosion resistance, and beautiful surface;Scope of application: mainly produces sheet metal and strip. Suitable for making all kinds of deep stamping products, and is widely used in various fields from cooking utensils to industrial equipment.

- Q:Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- The foil will not burn in a normal oven, it is best to oil it lightly as it can stick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords