2016 NEW-widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

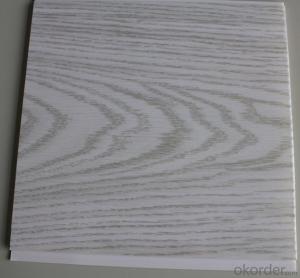

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture

PVC Foam Sheet

Estimated area of one hectare is being deforested every second in the world today. A large share of deforestation is being done to meet the global demand for wood. Currently world is facing serious ecological imbalance. Our Eco friendly CREATIVE PVC FOAM BOARD is made out of polymer with thermoplastic nature gives advantage of Re-cycling. Thus we can save lot of natural resources and can be a substitute of wood which ensures least damage to the environment

FAQ

Q1: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q:What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q:What are the requirements for plastic channel plate routing?

- Plastic board for dry field cooperation permanent wire laying groove plate wiring should be in the civil plastering dry after appearing, be close to the surface of the buildings to be flat vertical.

- Q:What are the insulation properties of plastic sheets?

- Plastic sheets generally have good insulation properties due to their low thermal conductivity. This means that they can effectively prevent the transfer of heat, cold, or sound, making them suitable for various insulation applications such as in buildings, electrical components, or packaging materials. Additionally, some plastic sheets can also provide electrical insulation, protecting against the flow of electric current.

- Q:What is the difference between ABS plate and HIPS plate?

- No, it's just that ABS has better resistance to chemicals, weather resistance, cold resistance and mechanical properties than HIPS

- Q:is 3.5 mil thick plastic sheeting thick enough to use for a backyard ice rink?

- 6 mil plastic sheeting at your hardware store is cheaper than 3.5 mil sheets bought at Walmart -- go figure

- Q:do that.

- Because they have not taken high quality photos of that region ~

- Q:Can plastic sheets be used for artistic projects?

- Yes, plastic sheets can be used for artistic projects. They are versatile and can be used for various art techniques such as painting, drawing, printmaking, and mixed media. Plastic sheets can be easily cut, shaped, and manipulated to create unique and innovative artworks. Additionally, their durability makes them suitable for outdoor installations or sculptures.

- Q:Nascar: true paint or plastic sheet?

- Depends on the team, the sponsor, and the race track. Most, if not all, of the short track cars are wrapped. Daytona and Talladega are the two tracks teams will use paint over a wrap. Paint is lighter than a sheet of plastic and every little bit counts.

- Q:What is the maximum temperature that plastic sheets can withstand?

- The maximum temperature that plastic sheets can withstand varies depending on the type of plastic. However, most common plastic sheets can typically withstand temperatures up to around 160-200 degrees Celsius (320-392 degrees Fahrenheit).

- Q:What glue is the adhesive between aluminum and plastic in aluminum-plastic plate?

- The adhesion between aluminum plate and plastic plate is adhesive resin, which is a kind of hot-melt adhesiveThe product form is a kind of roll film, also called macromolecule adhesive filmSuch as DuPont, Korea SK, Japan MITSUBISHI, and so on, can provide quality products

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 NEW-widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords