Galvanized Steel Coils Made In China With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

DESCRIPTION FOR GALVANIZED STEEL COILS:

Mian Quality Standard | JIS G3302, EN10346, DIN17162, ASTM A653/653M, GB2518 |

Process | hot dip galvanizing |

Process Speed | 1#. Max 120m/min, 2#. Max 130m/min |

Thickness | 1#. 0.25mm upto 1.20mm, 2#. 0.25mm upto 1.0mm |

Width | 900mm upto 1300mm |

Surface Finish | zero spangles, skinpassed, oiled,chromated, tension level, |

Coating | zinc layer mass on both sides from 30 g/m2 upto 180g/m2 |

Yield Strength | 220Mpa upto 750Mpa |

Weight per Coil | max 15,000kg |

Inner Diameter | φ 508mm |

Outer Diameter | max φ 2,050mm |

Finished Internal Diameter | Φ 508mm or φ 610mm |

Finished Coil Weight | 1#. max 10,000kg, 2#. max 15,000kg |

Packing | Mill's Export Standard Packing |

Capacity | 300,000 tons/year |

EXPORT STANDARD FOR GALVANIZED STEEL COILS:

-Axial and circumferential steel straps with seal (4 steel straps each)

-VCI Anti-rust kraft paper

-Water-proofing plastic

-Pearl wool (coil surface)

-Steel cover (coil surface/bore)

-Plastic cover (coil sides)

-Inside and outside corner protectors

Or According customers' requirements(Usually only for domestic)

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS FOR GALVANIZED STEEL COILS:FOB, CFR, CIF

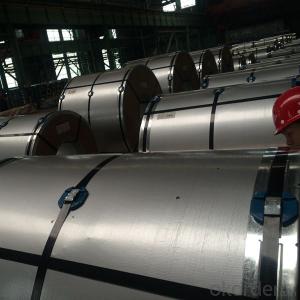

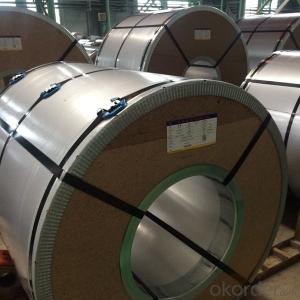

DETAILED PICTURES FOR GALVANIZED STEEL COILS:

APPLICATION FOR GALVANIZED STEEL COILS:

Galvanized steel products are mainly used in construction, light industry, automobile, agriculture , fishery and commercial industries. They have great advantages:1.it has small harm to the environment and it can be recycled, greatly lighten the stress to the environment.2.it is convenient to process,easy to construct and has good waterproof effect.

FAQ FOR GALVANIZED STEEL COILS:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

- Q:How do you prevent chloride-induced corrosion in stainless steel sheets?

- To prevent chloride-induced corrosion in stainless steel sheets, there are several measures that can be taken: 1. Material selection: Choosing the right grade of stainless steel that is resistant to chloride corrosion is crucial. Grades such as 316 or 317 are particularly effective in resisting chloride attack. 2. Surface treatment: Applying a passivation treatment to the stainless steel sheets can help enhance their resistance to chloride-induced corrosion. Passivation removes any surface iron contamination that may have occurred during fabrication, restoring the protective oxide layer. 3. Proper cleaning: Regular cleaning of the stainless steel sheets is essential to remove any chloride-containing contaminants that may have built up on the surface. Chloride ions can accumulate from saltwater, cleaning products, or other sources, so it is important to maintain a clean surface. 4. Avoid contact with chloride-containing substances: Minimizing exposure to chloride-containing substances can greatly reduce the risk of corrosion. This includes avoiding direct contact with saltwater, chloride-based cleaning agents, and chloride-rich environments such as swimming pools or coastal areas. 5. Design considerations: In environments where chloride exposure is expected, proper design considerations can help prevent corrosion. This may involve using protective coatings, minimizing crevices or gaps where chlorides can accumulate, and ensuring proper drainage to avoid stagnant conditions. 6. Regular maintenance: Regular inspections and maintenance of the stainless steel sheets can help identify and address any potential corrosion issues before they become severe. This may include repairing any surface damage, reapplying passivation treatments if necessary, and maintaining a clean surface. By following these preventive measures, the risk of chloride-induced corrosion in stainless steel sheets can be significantly reduced, ensuring their long-term durability and performance.

- Q:Are stainless steel sheets suitable for cleanroom applications?

- Yes, stainless steel sheets are highly suitable for cleanroom applications. They possess excellent corrosion resistance, durability, and a smooth surface that is easy to clean and maintain. Additionally, stainless steel sheets can withstand high temperatures and are resistant to chemicals, making them an ideal choice for cleanroom environments requiring high levels of cleanliness and hygiene.

- Q:Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not as effective as other materials specifically designed for soundproofing, it still has some soundproofing properties. Stainless steel sheets have a high density which helps in reducing sound transmission. Additionally, they have good reflective properties, meaning they can reflect sound waves and prevent them from passing through. However, it is important to note that for effective sound insulation, it is recommended to use materials specifically designed for this purpose, such as acoustic panels or soundproof curtains, as they offer better sound absorption capabilities.

- Q:What are the applications of stainless steel sheets?

- Due to their various beneficial properties, stainless steel sheets find a wide range of applications. Some common uses include: 1. Construction: Stainless steel sheets are widely utilized in the construction industry for various purposes. They provide durability, corrosion resistance, and an attractive appearance, making them suitable for cladding, roofing, wall panels, as well as structural components like beams, columns, and reinforcement bars. 2. Kitchenware: The production of kitchen appliances and utensils extensively involves stainless steel sheets. They are used to manufacture sinks, countertops, backsplashes, and cabinets. Stainless steel is preferred in the kitchen due to its hygienic properties, resistance to staining and corrosion, and ease of cleaning. 3. Automotive industry: Stainless steel sheets are utilized in the automotive industry for producing various components. They are used in the manufacturing of exhaust systems, mufflers, fuel tanks, and decorative trims. Stainless steel sheets offer corrosion resistance, heat resistance, and durability in harsh automotive environments. 4. Medical equipment: The medical field widely employs stainless steel sheets for the production of surgical instruments, implants, and medical equipment. The corrosion resistance and biocompatibility of stainless steel make it an ideal material for these applications. 5. Chemical processing: The chemical industry heavily relies on stainless steel sheets due to their corrosion resistance and ability to withstand high temperatures. They are used for manufacturing storage tanks, pipes, valves, and pressure vessels. Stainless steel sheets are preferred in chemical processing applications to prevent contamination and ensure process safety. 6. Energy and power generation: Stainless steel sheets are utilized in power plants, refineries, and other energy generation facilities. They are used in manufacturing boilers, heat exchangers, and condensers due to their high-temperature resistance, corrosion resistance, and strength. 7. Decorative applications: Stainless steel sheets are frequently employed in architectural and decorative applications. They are used for decorative panels, elevator doors, signage, and furniture. The versatility of stainless steel allows for various finishes and textures, making it a popular choice in interior and exterior design. In conclusion, stainless steel sheets are incredibly versatile and find numerous applications in various industries. Their corrosion resistance, durability, strength, and aesthetic appeal make them an ideal material for a wide range of purposes.

- Q:What's the difference between stainless steel 302 and 304?

- Plate type heat exchanger, corrugated pipe, household appliances (1, 2 kinds of tableware, kitchen cabinet, indoor pipeline, water heater, boiler, bath), auto parts (windshield wiper, muffler, mold), medical appliances, building materials, chemical, food industry, agriculture, marine parts, millet mobile phone etc.. 304 stainless steel is a nationally recognized food grade stainless steel.

- Q:Welding defects analysis of 1.5mm stainless steel plate

- Arc craterBecause the low-lying and arcing arc part formed in the end of the improper bead.Cause: short welding time of welding wire or electrode, insufficient filling metal.Hazard: 1. Reduce the cross-sectional area of the weld;The crater at incomplete reaction prone to agglomeration or segregation of impurities, so the arc pit often have porosity, slag, crack etc..

- Q:How do you calculate the bending radius for stainless steel sheets?

- In order to determine the bending radius for stainless steel sheets, several factors need to be taken into consideration. To begin with, the thickness of the stainless steel sheet must be determined. Thinner sheets necessitate smaller bending radii, whereas thicker sheets can accommodate larger radii. The type of stainless steel being used should also be identified. Various grades of stainless steel possess different levels of ductility, which impacts their ability to be bent. Higher ductility allows for smaller bending radii. Furthermore, the desired angle of the bend should be considered. The sharper the angle, the smaller the bending radius required. To calculate the bending radius, the following formula can be utilized: Bending Radius = (2 x Sheet Thickness) + (Bend Angle x Sheet Thickness) For instance, if a stainless steel sheet has a thickness of 0.5mm and a 90-degree bend is desired, the bending radius would be: Bending Radius = (2 x 0.5mm) + (90 x 0.5mm) = 1mm + 45mm = 46mm It is essential to note that this formula serves as a general guideline and may vary depending on the specific properties of the stainless steel being used. Consulting technical specifications or manufacturers' guidelines is always recommended for accurate bending radius calculations.

- Q:What are the different types of stainless steel sheets?

- There is a variety of stainless steel sheets to choose from, each with its own unique properties and uses. Here are some of the most commonly used types: 1. Austenitic stainless steel sheets are widely used due to their excellent corrosion resistance and high ductility. They are non-magnetic and can be easily formed, making them suitable for various applications like kitchen equipment, architectural structures, and automotive components. 2. Ferritic stainless steel sheets have a lower chromium content compared to austenitic stainless steel. They offer good corrosion resistance in specific environments and are often used in applications that require high temperature resistance, such as industrial ovens and exhaust systems. 3. Martensitic stainless steel sheets are known for their high strength and hardness. They are magnetic and provide good corrosion resistance, making them suitable for applications that require both strength and corrosion resistance, like knives, turbine blades, and valve parts. 4. Duplex stainless steel sheets combine the properties of both austenitic and ferritic stainless steels. They have excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel sheets are heat treatable, offering high strength and excellent corrosion resistance. They are commonly used in applications that require a high strength-to-weight ratio, such as aerospace components, springs, and shafts. These examples highlight the variety of stainless steel sheets available. The choice of which type to use depends on specific application requirements, considering factors such as corrosion resistance, strength, formability, and cost.

- Q:Can stainless steel sheets be used for cryogenic applications?

- Indeed, cryogenic applications can utilize stainless steel sheets. Stainless steel boasts remarkable mechanical properties, corrosion resistance, and low thermal conductivity, rendering it fitting for cryogenic settings. It endures frigid temperatures without succumbing to brittleness or weakening. Frequently, stainless steel sheets find employment in cryogenic applications like storage tanks, piping systems, and cryogenic equipment. Nevertheless, it is crucial to select the proper grade of stainless steel, specifically intended for cryogenic applications, to guarantee utmost performance and durability.

- Q:Are stainless steel sheets resistant to high-pressure environments?

- Yes, stainless steel sheets are highly resistant to high-pressure environments due to their exceptional strength, durability, and resistance to corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coils Made In China With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords