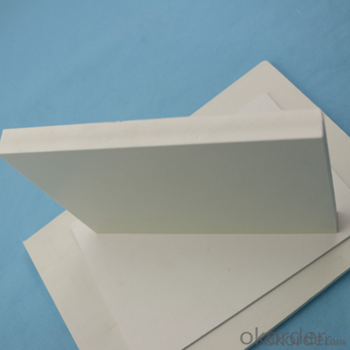

2016 PVC Foam Sheet For Furniture Wall Almirah Designs/PVC Foam Board for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

About us:

We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer.

We are specialized manufacturing PVC foam board. There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise. And now we have 6 production line for PVC foam board

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding

Specifications

Size : 915*1830 ,1220*2440

Thickness: 1.0-25.0mm

Density::0.45-1.05

Color : all colors

Application: for cupbaord

pvc foam board

Specifications

1. Waterproof and mould proof,

2. Widely used in kitchen and washroom cabinet,

3. Thickness from 1mm to 25mm, different density,

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed.

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house,

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet

Specifications:

1 width: 1220mm.

2 Length: 2440mm or as per your requirement.

3 Thickness: From 1mm to 25mm.

4 Density: From 0.5 to 0.8

FAQ:

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: If the products have some quality problem ,how will you deal with it?

A: 1,If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

2,Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Product Photo

- Q:I was wondering if it was possible to run a plastic binder cover (like the kind you use with a comb binding machine) through my printer? I'm not sure if the ink would even actually stick to it... or if it might even melt in my new printer? I have a new Kodak ESP3... so I don't want to mess it up! Anyone know? I know you can buy clear sheets made for the inkjet printers... but I didn't know if these were different... Thanks in advance.

- the binder covers a to slick for the ink to stick to. the overhead clear plastic printable sheets are a bit thin for use as covers. There are Thermal plastic sheets that will take printing...ask some graphic engineer...they use it for overlays on plans.

- Q:This plastic is used instead of clay as flooring for salt bed

- You can try shower curtains . It works well but you have to pay attention to the material .

- Q:For my Drawing on the Right Side of the Brain course, Betty Edwards includes a view finder containing an overhead projector sheet as one of the materials. I assumed any sheet of plastic (i.e. a plastic sleeve made for a binder) would work, but now I discovered she wants the reader to write on it using a white board marker (and wipe it off afterwards). Any ideas on how I can get a one or two overhead projector sheets, or else, are there any easy alternatives?

- Try an art store. You can often buy individual sheets of various kinds of paper and other materials. The ghetto way would be to scour your home for transparent plastic from product packages and see if any of them work. Lots of things come wrapped in clear plastic, especially electronics. For example, a brand new laptop usually has a clear plastic film over the LCD for protection which would probably be ideal.

- Q:I'm looking for thinner, colored, plastic sheets that I can use to punch my own confetti with shape punches. Something similar to the thickness you get when you buy plastic confetti. Any idea where I can find those, or if there is a specific name for them?

- Depends on the plastic, but laminate sheets would commonly soften. Most laser printer have fuser temperatures at or around 400F, so only plastics exceptionally made for laser printers will have to be used.

- Q:How are plastic sheets made?

- Plastic sheets are typically made through a process called extrusion, where melted plastic is forced through a die to form a continuous sheet. The plastic pellets are first melted and then fed into a heated barrel, where they are forced through a rotating screw. The molten plastic is then pushed through a flat die, which determines the thickness and width of the sheet. As the plastic exits the die, it is cooled and solidified using either air, water, or a combination of both. The resulting plastic sheet can be cut and shaped according to specific requirements.

- Q:My basement is filled with the stuff but it's almost 10 years old by now.

- Duct tape should be replaced when the sides of the roll get furry.

- Q:Are plastic sheets resistant to discoloration from outdoor exposure?

- Yes, plastic sheets are generally resistant to discoloration from outdoor exposure.

- Q:Can plastic sheets be used for vacuum forming?

- Yes, plastic sheets can be used for vacuum forming.

- Q:Are plastic sheets resistant to degradation from cleaning agents?

- Yes, plastic sheets are generally resistant to degradation from cleaning agents.

- Q:How do plastic sheets compare to PVC sheets?

- Plastic sheets and PVC sheets are essentially the same thing. PVC stands for polyvinyl chloride, which is a type of plastic material. Therefore, there is no significant difference between plastic sheets and PVC sheets as they both refer to sheets made from the same material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 PVC Foam Sheet For Furniture Wall Almirah Designs/PVC Foam Board for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords