Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Wooden Coating Aluminium Coils for Rolling Shutter Doors

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Coating Aluminium Coils for Rolling Shutter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Coating Aluminium Coils for Rolling Shutter Doors

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

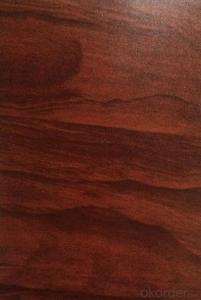

5. Image of Wooden Coating Aluminium Coils for Rolling Shutter Doors

6. Package and shipping of Wooden Coating Aluminium Coils for Rolling Shutter Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum pipes be bent or shaped easily?

- Yes, aluminum pipes can be bent or shaped easily. Aluminum is known for its malleability, which means it can be easily shaped or formed without cracking or breaking. This characteristic makes aluminum pipes a popular choice in various applications where flexibility is required. Aluminum pipes can be bent using a variety of methods such as cold bending, rotary draw bending, or heat induction bending. Additionally, they can also be shaped through processes like extrusion or rolling. The ease with which aluminum pipes can be bent or shaped makes them a versatile option in industries such as construction, automotive, and aerospace.

- Q:Can aluminum pipes be used for plumbing?

- Yes, aluminum pipes can be used for plumbing. Aluminum is a lightweight and corrosion-resistant material that is commonly used in plumbing systems for water supply and drainage. It is often preferred for its durability, flexibility, and ease of installation. However, it is important to note that aluminum pipes should be properly protected against galvanic corrosion when in contact with certain metals, and their use may be restricted in specific applications due to local building codes and regulations.

- Q:Air conditioning copper aluminum tube how to connect? It's broken at the copper aluminum pipe joint. What should I do?

- Welding of copper and aluminum is an international welding problem, traditional methods commonly used in the tin welding of copper and aluminum, but the molding method is not good, and not a good strength, can not be applied to actual production, so far, can be used for welding copper and aluminium materials few, two kinds of low temperature welding copper and aluminum welding materials are now introduced to everyone, it is easy to solve the welding between the two kinds of metal.1:M51 welding wire diameter of 3.2mm, temperature of 179 degrees can be used for welding welding, gas welding or soldering iron, of course like better reflow machine equipment like effect, easy temperature control, good fluidity, non-toxic, single-sided double-sided molding welding, tensile strength after welding for 13kg/mm2.2:MG460 welding wire, welding wire specification, diameter 1.6mm, low temperature 260 degrees can be welded, simple operation, welding mode is the same as above, the tensile strength after welding is 18kg/mm2, the fluidity is better than M51.

- Q:In 2006, the air conditioning in the market, some brands will connect pipes from copper tubes to aluminum tubes, and now want to ask what brand of aluminum tubes?The more the brand, the better. Be sure to be real

- CHIGO, Galanz, Midea, TCL, LG.But in Beijing seems to have not listed, may be the year after next, and other big cities should be sold, it is a trial bar.

- Q:What is the difference between aluminium pipe and aluminium alloy pipe?

- Aluminum tube refers to a pure aluminum or aluminum alloy by extrusion processing into its longitudinal length of hollow metal tubular material. There may be one or more closed through holes with uniform wall thickness and cross section to be delivered in a straight or coiled form. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery and electrical, home and other industries.

- Q:6063, aluminum pipe welding with what kind of welding rod?

- ER4043, ER4047, ER5183, ER5356, ER5554, ER5556, ER5654... Yes, it depends on your assessment.

- Q:Because there is no copper tube in the refrigerator nowMost are replaced by aluminium tubes or iron pipesI want to know whether the evaporation tube is better than the copper tube or the iron tube!Besides, what kind of condenser is used in the refrigerator? Is it an aluminum tube or an iron tube?The condenser is broken. Is it particularly difficult to repair?!How much would it cost to replace the evaporating and condensing tubes into copper tubes?!

- The evaporating pipe of the refrigerator, except the copper tube, is good for the aluminum pipe, and the iron pipe is easy to rust.1, now the refrigerator tube is the use of aluminum tube or Bondi tube (Bondi tube, that is galvanized steel pipe, in fact, iron pipe, iron pipe above the paint once lost, it is easy to rust)2, aluminum pipe than iron pipe relative corrosion, iron pipe is not corrosion resistance, so suggest the choice of aluminum pipe.3, in fact, the best or copper pipe, but now there is no factory production, mainly cost.This material can be seen, usually screen tube, that is, Bondi tube (Tie Guan), is plate like, that is, aluminum. Under normal circumstances can use 10 years, this is tested, while others are in the middle may be bad.

- Q:Will the aluminum tube (6063) anodized after the local needle hole shaped point, what is the reason for it, is the material problem or oxidation plant corrosion?

- You are the light, or the fog, if light, are certainly no oxidation treatment, that is, if the surface is like fog, that is normal.

- Q:Who knows the grease on the aluminium tube cleaning method

- You can only use neutral detergent such as detergent.

- Q:Why are copper tubes used in household air conditioners and aluminium tubes for automotive air conditioners?

- The difference between air conditioning copper tube and aluminum tube:1 、 the material of copper tube and aluminum pipe is different.2, the copper pipe and aluminum pipe flow is different.3, copper and aluminum prices are different: Copper costs high.4, the application of copper and aluminum, brass, good ductility, resistance to oxidation, bellbottom do good pressure resistance, not easy leakage of refrigerant, are often used in air conditioning; aluminum can do bell, pressure difference of oxidation resistance, it is prone to leak, if not good insulation cotton, it is a hidden danger.5, copper and aluminum bending: aluminum tube bending, better than copper bending resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords