Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

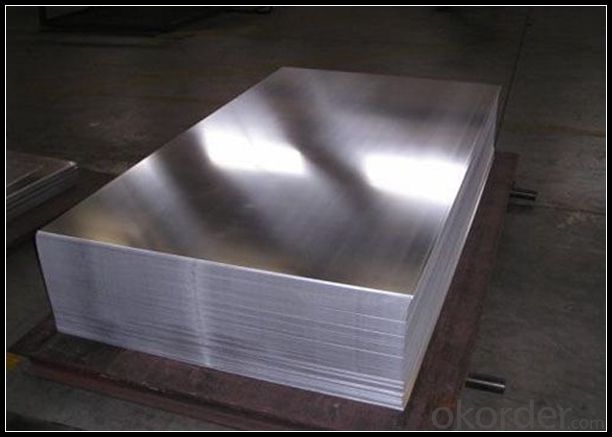

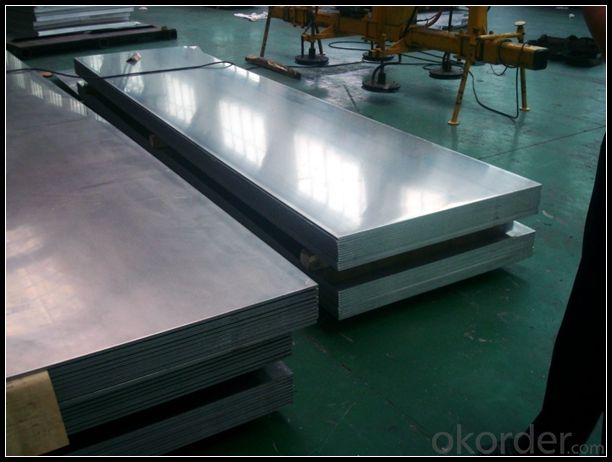

5. Image of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

6. Package and shipping of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are often used in aerospace wing structures due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance.

- Q:you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q:How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

- Q:What are the different methods of forming aluminum sheets?

- There are several methods of forming aluminum sheets, each with its own advantages and applications. Here are some of the different methods: 1. Rolling: Rolling is the most common method used to form aluminum sheets. In this process, a large aluminum ingot is passed through a series of rolling mills, which gradually reduce its thickness and increase its length. The ingot is rolled multiple times until the desired thickness is achieved. Rolling can produce aluminum sheets of various thicknesses and widths, making it versatile for different applications. 2. Extrusion: Extrusion is another method used to form aluminum sheets, especially for complex cross-sectional profiles. In this process, a heated aluminum billet is forced through a shaped die, resulting in a continuous length of aluminum with the desired shape. Extrusion allows for the creation of intricate designs and is often used in the production of structural components and frames. 3. Casting: Casting is a method used to form aluminum sheets with a specific shape or pattern. In this process, molten aluminum is poured into a mold and allowed to cool and solidify. The mold can be made of various materials, such as steel or sand, depending on the complexity of the desired shape. Casting is commonly used for decorative purposes and in the production of architectural panels. 4. Stretch forming: Stretch forming is a specialized method used to form aluminum sheets into curved or contoured shapes. In this process, the sheet is clamped at its edges and stretched over a form, using hydraulic or mechanical forces. As the sheet is stretched, it conforms to the shape of the form, resulting in a curved or contoured sheet. Stretch forming is commonly used in the aerospace and automotive industries for components such as fuselage sections and car body panels. 5. Pressing: Pressing, also known as stamping or punching, is a method used to form aluminum sheets into specific shapes or patterns. In this process, the sheet is placed between a die and a punch, and pressure is applied to deform the sheet. The die and punch can have various designs and can create shapes ranging from simple cutouts to intricate patterns. Pressing is commonly used in the manufacturing of automotive parts, appliances, and electronic enclosures. These are just a few of the different methods of forming aluminum sheets. Each method offers unique advantages and is chosen based on the specific requirements of the desired shape, thickness, and application of the aluminum sheet.

- Q:What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance due to the formation of a protective oxide layer on their surface, which prevents further oxidation or corrosion.

- Q:I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- yes the price is up right now.

- Q:What are the different types of surface coatings for aluminum sheets?

- There are several types of surface coatings available for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q:Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q:we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Look up the atomic mass of aluminum on your periodic table, multiply by 107, then divide by .47g?

- Q:What are the different methods for engraving aluminum sheets?

- There are several methods for engraving aluminum sheets, including laser engraving, rotary engraving, chemical etching, and mechanical engraving. Each method offers unique benefits and can produce high-quality results depending on the desired outcome and specific requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords