PVC Foam Board PVC Sheet for Thermoforming

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Colors: white, black,yellow, blue, green, red, or as per your requirement;PVC board is made through foaming and pressing into shape with additives.

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

The material is of sound insulation, heat insulation, noise absorption, heat preservation and corrosion prevention, etc.

Good ignition retardance, self-extinguishing against fire to prevent fire accident.

The series products are moisture resistant and mould proof, don't absorb water and have good shock-proof performance.

Processed by weather-resistance formula, this product is not easy to age and can keep its color for long.

Small weight of this product facilitates storage and construction.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

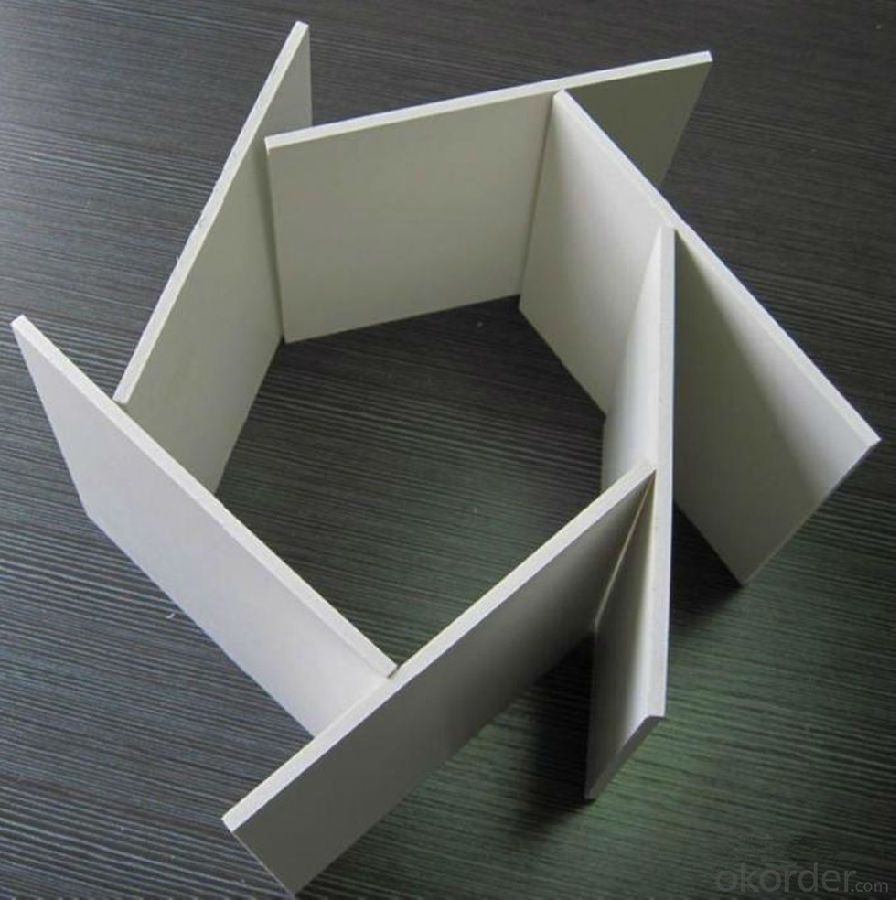

5.Pictures of PVC Foam Board

6.Factory Pictures

- Q:Which is better, the aluminum pinch plate and the PVC pinch plate?

- 1, with excellent corrosion resistance, to resist a variety of soot, damp environment, anti ultraviolet.2, environmental protection, non-toxic, tasteless, anti-static, dust free, easy to wash, high hardness, fire, non stick stains.3, low cost, longer service life, and not easy to aging, subsidence, discoloration, deformation.4, high grade, and tiles, bathroom, kitchen cabinets easily form a unified style.

- Q:They need to be non-adhesive.

- Spray it with acrylic wax

- Q:I'm tired of pulling grass out of my flower bed, I have put two layers of black plastic down and mulch and I have sprayed it with a safe against shrub grass killer. Please help!

- Yes, grass will rear its ugly little head even with black liner, mulch etc...Just when you see weed, pull it. I have my kids even pulling weeds now because they know they are not supposed to be there. If you do it every morning, you'll get a hanle on the weeds and you'll be okay and weed free.

- Q:Can plastic sheets be used for hygienic wall cladding?

- Yes, plastic sheets can be used for hygienic wall cladding. Plastic sheets, such as PVC panels, are commonly used for wall cladding in areas that require high levels of hygiene, such as commercial kitchens, hospitals, and food processing facilities. These sheets are easy to clean, resistant to moisture and chemicals, and provide a smooth and durable surface that helps maintain a hygienic environment.

- Q:Can plastic sheets be used for picture frame backing?

- Yes, plastic sheets can be used for picture frame backing. They are commonly used as an alternative to traditional cardboard or foam board backing due to their durability and resistance to moisture. Plastic sheets such as acrylic or polystyrene can provide a protective layer for the artwork while maintaining a lightweight and transparent appearance.

- Q:Can plastic sheets be used for outdoor furniture?

- Yes, plastic sheets can be used for outdoor furniture. They are resistant to weather conditions, durable, and easy to clean, making them a popular choice for outdoor applications.

- Q:How do I get rid of the static in the stack of the clear plastic cover sheets? Every time I try to pull one, I get shocked viciously!!It's within the entire stack. Help!

- Staticide. okorder /

- Q:I got the thick 4mil, does it work better with a space between the window and film? My neighbor puts the film right on the window, does that help? I think a still-air space would work better. How much does it really help, 5%?

- You are correct that an air-gap would provide much better insulation than the film directly in contact with the window, and, I would expect it to improve your heating expenditures by no more than about 15% or so.

- Q:Put some drops of water on a glass or plastic sheet. After evaporation we seesome white spots like dust over?

- If I'm not mistaken, these white spots are actually caused by dust and dirt in the air that were caught by the water, and they are left behind after evaporation.

- Q:I'm trying to create design a template to spray-paint a logo on a wooden table.

- Purchase thin plexiglas sheets, of desired thickness, from a builders supply store. Layout your design on the surface and cut it out with a fine bladed jig saw. You may have to drill some holes to start your cuts in isolated areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board PVC Sheet for Thermoforming

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords