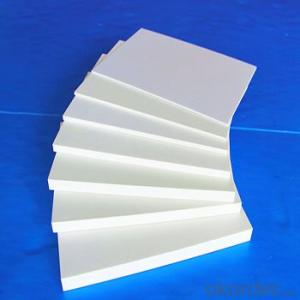

PVC Foam Board Transparent Flexible PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

2. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black,as required

3 .Product usage:

1.Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

4.Product Application

Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.PVC foam board part of the end product icon:

6.product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

7.PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

8. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

9. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

10.pictures of factory

- Q:the upper plastic sheet is bendable and the lower sheet is rigid. I need some type of glue that I could brush on easily to stick them together.. Since I may need alot of that glue, are there cheaper options for me?

- Not knowing what type of plastic it is, the only two glues that may work are; Superglue; if it doesn't work, then try; PVC plumbers glue. Both can be purchased at a Big Box home Improvement Store for cheapest prices, or your local hardware store. Vapors from the PVC glue are flammable and toxic, so use in a well ventilated area only. Work safe, be safe. Good Luck with the project.

- Q:Can plastic sheets be used for greenhouse coverings?

- Yes, plastic sheets can be used as an effective and affordable option for greenhouse coverings. They allow sunlight to penetrate while providing insulation to retain heat and protect plants from harsh weather conditions.

- Q:Can plastic sheets be used for DIY projects in home improvement?

- Yes, plastic sheets can definitely be used for DIY projects in home improvement. They are versatile, durable, and come in various sizes and thicknesses. Plastic sheets can be used for a wide range of applications such as creating protective barriers, constructing temporary walls, making custom storage solutions, or even crafting decorative elements. They are easy to work with and can be cut, shaped, and fastened using commonly available tools. Additionally, plastic sheets are often cost-effective and resistant to moisture, making them suitable for both indoor and outdoor projects.

- Q:Can plastic sheets be used for protective shields in sports?

- Yes, plastic sheets can be used for protective shields in sports. They are commonly used in various sports such as hockey, baseball, and football to provide a barrier between players and potential injuries. Plastic sheets offer impact resistance, transparency, and lightweight properties, making them suitable for protecting athletes from flying objects or accidental collisions.

- Q:Can plastic sheets be used for construction purposes?

- Yes, plastic sheets can be used for construction purposes. They are commonly used in applications such as roofing, insulation, and as protective barriers. Plastic sheets offer various advantages including durability, lightweight, easy installation, and resistance to moisture and chemicals.

- Q:Are plastic sheets resistant to chemicals used in pools?

- Yes, plastic sheets are typically resistant to chemicals used in pools.

- Q:These sheets should be non-transparent, pure white, 4-6mil in thickness, and relatively stiff (not like that used for plastic bags, but rather like mylar sheet).

- Most hobby shops should be able to supply you with this type of material. If they do not have it then they should be able to locate a supplier for you or at least get you a catalog that would allow you to purchase modeling materials. The link below is for a company that sells many plastic sheets and scaled plastic structural members for railroad models and that type of thing. Send for that catalog.

- Q:Are plastic sheets resistant to tearing?

- Yes, plastic sheets are generally resistant to tearing due to their strong and flexible nature. However, the level of tear resistance can vary depending on the thickness and quality of the plastic sheet.

- Q:I want to form plastic sheet using heat. Will this work? Plug a rheostat into the wall. Plug a cord into the rheostat. Cut the end of the cord and attach the bare ends to a piece of sheetmetal. Will this heat the metal w/o it being a shock hazard?

- And this, ladies and gentlemen, is arguably the best way to burn your house down.

- Q:I think the cheese slices that are not placed in these individual plastic sheets tastes better. Why do they do this?

- Convenience is an important feature of their brand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board Transparent Flexible PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords