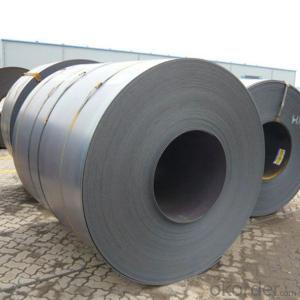

Hot Rolls Steel Coils Steel Plates Steel Sheets Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:What are the common coil loading and unloading procedures?

- The common coil loading and unloading procedures typically involve the use of specialized equipment such as cranes or forklifts to safely lift and transport the coils. The procedure may vary depending on factors such as the size and weight of the coils, as well as the specific requirements of the industry. Generally, the coils are loaded or unloaded by carefully positioning them onto or off of a designated storage area or transportation vehicle. The process often includes securing the coils with straps or clamps to prevent any movement or damage during transportation. Proper handling and adherence to safety protocols are crucial to ensure the successful loading and unloading of coils.

- Q:That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- Uh. . . your guitar would be okay. . . except your strings wouldn't last long then nylon strings.

- Q:How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers to provide strength and durability to the trailer's frame and structure. The coils are typically shaped and welded together to form the trailer's chassis, ensuring it can withstand heavy loads and withstand the rigors of agricultural use.

- Q:What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on its intended use and manufacturing specifications. However, common dimensions for a steel coil typically range from 0.15 to 3.5 millimeters in thickness, and 600 to 2,000 millimeters in width. The inner diameter of the coil can be around 508 to 610 millimeters, and the maximum outer diameter can be up to 2,000 millimeters.

- Q:How are steel coils used in the production of agricultural systems?

- Due to their durability and strength, steel coils are frequently employed in the production of agricultural systems. Specifically, these coils are commonly utilized in the creation of machinery and equipment essential for agricultural operations. One prevalent use of steel coils lies in the manufacture of farming machinery such as tractors, plows, and cultivators. These machines necessitate robust components capable of enduring the challenging conditions present in the agricultural environment. Steel coils are employed to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Additionally, steel coils are employed in the creation of irrigation systems, which play a crucial role in efficient water management within agriculture. These coils are employed in the construction of pipes, valves, and fittings, ensuring the durability and long-lasting nature of the irrigation system. Furthermore, steel coils are employed to fabricate storage tanks and silos, which serve as vital tools for storing and preserving agricultural products like grains, seeds, and fertilizers. Moreover, steel coils find application in the construction of greenhouses and agricultural buildings. These coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also employed in the production of fencing and enclosures to safeguard crops and livestock from external threats. In conclusion, steel coils play a significant role in the production of agricultural systems by delivering the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their utilization ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q:What are the different methods of corrosion protection for steel coils?

- There are several different methods of corrosion protection for steel coils, each with its own advantages and disadvantages. 1. Coating: One of the most common methods is to apply a protective coating to the steel coils. This can be done through a variety of techniques such as hot-dip galvanizing, electroplating, or painting. Coatings provide a barrier between the steel surface and the corrosive environment, preventing direct contact and thus reducing the risk of corrosion. 2. VCI (Vapor Corrosion Inhibitor): Another method is the use of VCI materials, which release chemicals that inhibit corrosion when in contact with the steel surface. These materials can be applied as coatings, films, or papers, and are particularly useful for long-term storage or shipping of steel coils. 3. Cathodic Protection: This method involves the use of sacrificial anodes or impressed currents to protect the steel coils. Sacrificial anodes, typically made of zinc or aluminum, are connected to the steel surface. These anodes corrode instead of the steel, sacrificing themselves to protect the coils. Impressed current systems use a direct electrical current to prevent corrosion on the steel surface. 4. Wrapping and Packaging: Proper wrapping and packaging of steel coils can also provide corrosion protection. This includes using moisture barrier films, desiccants, or absorbent materials to reduce the moisture content around the coils. Additionally, ensuring adequate ventilation and avoiding contact with other corrosive substances can help prevent corrosion. 5. Environmental Control: Controlling the environment in which the steel coils are stored or used is crucial for corrosion protection. This may involve maintaining proper humidity levels, controlling temperature, and managing air quality. By minimizing exposure to corrosive elements such as moisture, salts, or chemicals, the risk of corrosion can be significantly reduced. It is important to note that the choice of corrosion protection method depends on various factors such as the specific application, budget constraints, and desired lifespan of the steel coils. A combination of these methods may also be used to provide enhanced protection against corrosion.

- Q:this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- it sometimes rusts

- Q:Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q:How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped into various parts, ensuring the turbines have a sturdy and durable construction. Additionally, steel coils are employed in the manufacturing of the turbine blades, providing strength and reliability to withstand the forces of wind.

- Q:I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- I have a combination of them both. I have Le Creuset enameled cast iron dutch-ovens, pots and pans; as well as All Clad stainless steel saute and deep-rimmed pans which have a copper core. I have one non-stick pan that I use for cooking eggs in.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolls Steel Coils Steel Plates Steel Sheets Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords