Non-woven Geotextile Fabric100% PP Spunbond Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

About K&D Non Woven Fabric:

1) Composition: 100% polypropylene

2) Weight: 10 - 300gsm

3) Width: maximum 2.4m wide (can be splited)

4) Various colors available

5) Characteristics: environmentally-friendly, good tensile strength, soft, lightweight,

non-toxic, water-resistant, air permeable

6) Usage:

a).daily use: making shopping bags, suit cover, surgical cover, cloth interlining, table cloth, bed sheet etc.

b). In agriculture: to protect the crop from pest harm, allows water, air and fertilizer to penetrate and reduces moisture evaporation.

c). in industry: to wrap to drainpipe etc.

7) Auxiliary treatment: UV protection, anti-virus, fire-retardant, antistatic, hydrophilic

8) Customers' specifications available

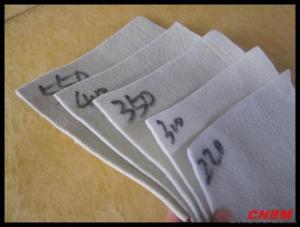

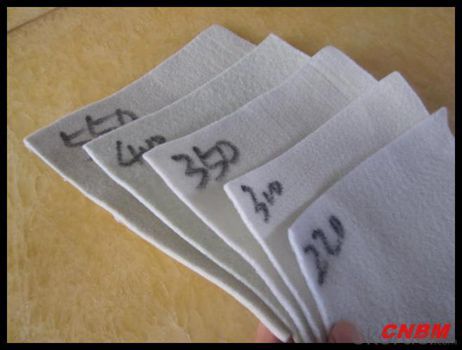

Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Are geotextiles suitable for use in stormwater management systems?

- Yes, geotextiles are suitable for use in stormwater management systems. They have proven to be effective in filtering sediment and pollutants from stormwater runoff, reducing erosion, and promoting infiltration. Geotextiles can enhance the performance and longevity of stormwater management systems by providing additional support, strength, and stability to the infrastructure.

- Q:What are the different installation guidelines for geotextiles in reinforcement projects?

- The installation guidelines for geotextiles in reinforcement projects typically involve the following steps: 1. Site Preparation: Clear the construction area of any vegetation, debris, or loose soil. Level the ground and remove any protrusions or sharp objects that could damage the geotextile. 2. Geotextile Placement: Unroll the geotextile over the prepared area, ensuring it covers the entire project site. Overlaps between adjacent rolls should be at least 1 to 2 feet to provide proper continuity. 3. Anchoring: Secure the geotextile at the edges using anchor trenches, stakes, or other appropriate methods to prevent movement during installation or in the long term. 4. Jointing: Overlap adjacent geotextile panels by a minimum of 1 to 2 feet, depending on the project requirements. Secure the overlap with appropriate fasteners or adhesives to ensure proper functioning. 5. Protection: If necessary, cover the geotextile with a protective layer, such as a layer of soil or aggregate, to shield it from potential damage during construction activities or exposure to UV radiation. 6. Compaction: If the project involves soil stabilization or reinforcement, follow the recommended compaction procedures to ensure proper integration of the geotextile with the surrounding soil or aggregate. 7. Quality Control: Regularly inspect the geotextile installation to ensure that it is properly placed, free of damage, and functioning as intended. Any identified issues should be addressed promptly. It is important to note that specific installation guidelines may vary depending on the project type, site conditions, and the type of geotextile being used. It is recommended to consult the manufacturer's recommendations and seek professional guidance to ensure proper installation.

- Q:How to judge the geotextile test results are reliable

- Different methods, different detection methods will lead to different results. But you can get the authority of the provincial inspection hall, do the test report

- Q:Characteristics of filament geotextile

- It can replace the traditional engineering materials and construction methods, construction safer, and contribute to environmental protection, can be more economical, effective and lasting solution to the basic problems in the construction. Filament geotextile has good mechanical function, good water permeability, and can be anti-corrosion, anti-aging, with isolation, filtration, drainage, protection, stability, reinforcement and other functions, to adapt to uneven grass-roots, Damage, creep small, long-term load can still maintain the original function. Filament geotextile characteristics: strength - the same weight under the specifications, the tensile strength are higher than other acupuncture non-woven fabrics; anti-ultraviolet light - with high UV resistance; high temperature resistance - resistance High temperature up to 230 ℃, high temperature remains structural integrity and the original physical properties; permeability and flat drainage - geotextile thick and is needle-shaped, with good surface drainage and vertical permeability, years later Can maintain this performance; creep resistance - geotextile creep resistance is better than other geotextiles, so long effect is good. It can resist the erosion of common chemical substances in soil and resistance to gasoline, diesel and other corrosion; ductility - geotextile under a certain stress has a good elongation, so that it can adapt to uneven irregular base; Cloth technical features: thick geotextile, geotextile can guarantee the three-dimensional porosity, is conducive to the realization of excellent hydraulic performance. Geotextile break strength has a great advantage, especially for retaining walls and embankment reinforcement. Geotextile indicators are more than the national standard, is an excellent geotextile reinforced materials.

- Q:Geotextile mouth chain suture is what kind of picture

- Hello I am a professional geotextile and other geotextile materials,

- Q:Geotextile what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber.According to the manufacturing method is divided into: there are two types of textile and non-woven geotextile geotextile with anti- Filter, drainage, isolation, reinforcement, protection, sealing and other functions, it is compared with conventional masonry and concrete anti-seepage effect, with low investment, simple construction process, short duration, good anti-seepage effect, effective channels The use of high coefficient of the advantages of water conservancy project dam and slope protection, channel isolation, seepage; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; Construction of the soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; landfill, thermal power plant ash dam, concentrator tailing dam isolation, seepage; geotextile has been widely used in infrastructure construction , And gradually applied to a wider range of areas.

- Q:How do geotextiles help with vegetation establishment in landscaping projects?

- Geotextiles help with vegetation establishment in landscaping projects by providing a stable and favorable environment for plants to thrive. They prevent soil erosion, retain moisture, and control weed growth, which ultimately promotes healthy root development and successful establishment of vegetation.

- Q:In the laying of composite geotextile water layer, what is wf115-0.2mm type

- Supply of composite geotextile, geomembrane.

- Q:Geotextile geomembrane factory need to record, certificate, inspection report?

- 0534- His highest answer the best

- Q:Thank you, great gods

- Polyester short wire, polyester filament, polypropylene geotextile, filament woven geotextile, and so on. I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven Geotextile Fabric100% PP Spunbond Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords