Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

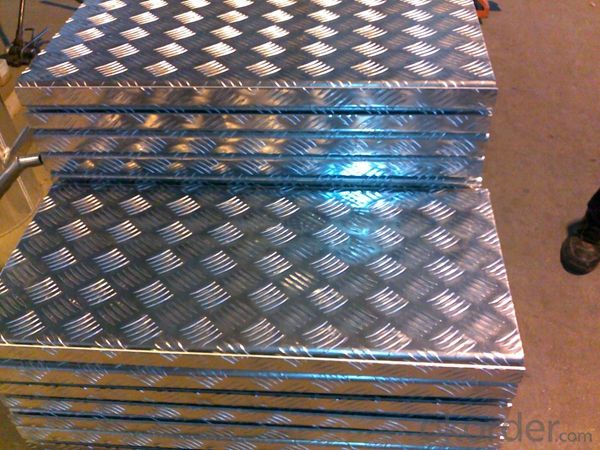

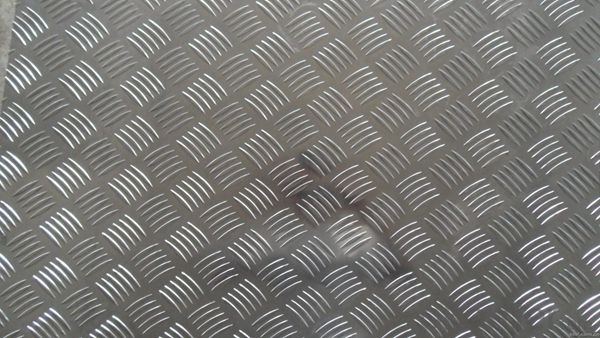

5. Image of Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

6. Package and shipping of Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

- Q:What is the cost of an aluminum sheet?

- The cost of an aluminum sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or conduct market research to get accurate and up-to-date pricing information.

- Q:What are the maximum dimensions of aluminum sheets?

- Different suppliers may have varying manufacturing capabilities, resulting in aluminum sheets having different maximum dimensions. Generally, aluminum sheets are offered in a diverse range of sizes to cater to different application needs. Typically, aluminum sheets can have a maximum width of 72 inches (6 feet) and a maximum length of approximately 240 inches (20 feet). These dimensions offer sufficient material for various projects, such as construction, manufacturing, and industrial applications. However, it is essential to consider that individual suppliers may have their own restrictions. Therefore, it is recommended to directly consult with them to ascertain the maximum dimensions available for aluminum sheets.

- Q:I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- In the novel, developed from the original screenplay (which featured information that did not end up being mentioned in the film), Scotty was already aware that the chap he gave the transaprent aluminium formula to was recorded as its inventor. Therefore, the plot as intended suggested looped or self-generating causality. This is the outcome referred to in other predestination paradoxes, like the one about going back in time 100 years and becoming your own great-grandfather. The character in the film who Scotty gives the formula to is called Marcus Nichols. he was played by an American actor called Alex Henteloff. For reasons of brevity or simplicity of plot, the film leaves the viewer thinking that Scotty et al didn't know who the inventor was, but Scotty does have the line How d'you know he wasn't the man who invented it?, delivered to Dr McCoy, which could be taken as an indication that Scotty DID know and was just being a smart-**** to McCoy. As a thought experiment, this wouldn't prove the existence of multiple universes, just that the outcome was possible without changing their own future. Proof would require more information that is also missing from the screenplay and film. In reality, there is no such thing as transparent aluminium, but there are aluminium-based ceramics which are transparent.

- Q:I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- ensure u have distilled water cuz if there is salt in it, u might finally end up freeing chlorine interior the air and die. haha. ok, take a 9 -12 volt battery or something like that and placed 2 wires from the positve and unfavourable ends interior the water. the only cord that bubbles extra is the hydrogen. so turn a attempt tube and placed it interior the water and so as that there is not any air interior the attempt tube. whilst the cord is going in, the hydrogen will fill it up and u'll be left with organic hydrogen interior the tube. i don't be conscious of if i defined it perfect yet there are a team of video clips on youtube. examine them out.

- Q:What are the different forming techniques for aluminum sheets?

- There are several different forming techniques that can be used to shape aluminum sheets. One common technique is called bending, which involves applying force to the sheet to bend it into a desired shape. This can be done manually using a press brake or through automated processes such as roll forming or stretch forming. Another technique is called deep drawing, which involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This process is commonly used to create cylindrical or box-shaped components like cans or containers. Hydroforming is another forming technique that can be used for aluminum sheets. It involves using hydraulic pressure to shape the sheet against a mold or form. This technique is often used to create complex, irregular shapes that would be difficult to achieve with other methods. Spinning is a technique that is commonly used to create symmetrical shapes such as bowls or cones. It involves rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Finally, there is also a technique called stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is often used for high-volume production of components such as automotive body panels. Overall, these forming techniques offer a range of options for shaping aluminum sheets into various forms and designs, allowing for flexibility and versatility in manufacturing processes.

- Q:The corrosion of the aluminum sheet that I request is friction during operation, not the surface of the container after the passivation of the surface of the container containing sulfuric acid. I'd like to use the evaporating plate, the evaporator fin and so on for the cooling in the quick freezing equipment. The ice of ice making machine is attached to the aluminum plate after anodic oxidation or passivation. When it is peeled off, it will cause friction to the surface of the aluminum plate and block the passivation layer, which will make the aluminum plate easier to corrode.

- Directly on the surface coating H2SO4Because the AL and H2SO4 react to produce a dense oxide film that prevents corrosion again, the barrel containing sulfuric acid can be made from AL

- Q:Are the aluminum sheets suitable for manufacturing electronics components?

- Yes, aluminum sheets are suitable for manufacturing electronics components. Aluminum is a lightweight, durable, and cost-effective material that is widely used in the electronics industry. It has excellent electrical conductivity, which is essential for the proper functioning of electronic devices. Aluminum sheets can be easily shaped, cut, and formed into various components such as heat sinks, enclosures, and connectors. Additionally, aluminum has good thermal conductivity, allowing it to effectively dissipate heat generated by electronic components. This makes aluminum sheets an ideal choice for manufacturing electronics components.

- Q:What are the different methods of cutting aluminum sheet?

- Various methods exist for cutting aluminum sheet, each offering unique advantages and applications. 1. Shearing: Employing a sharp blade, shearing provides a quick and efficient process for straightforward cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: By utilizing a high-powered laser beam, laser cutting achieves precise and clean cuts. This method is ideal for intricate designs, allowing for detailed and accurate cuts. Additionally, laser cutting can be automated, making it suitable for large-scale production. 3. Waterjet cutting: With a high-pressure stream of water mixed with abrasive materials, waterjet cutting is versatile and capable of handling various materials and thicknesses. It produces smooth and precise cuts without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, resulting in a cut. It is a fast and cost-effective method, particularly for thicker sheets. However, the cut may not be as clean as laser or waterjet cutting. 5. CNC milling: By employing a rotating cutting tool, known as Computer Numerical Control (CNC) milling, material is removed from the aluminum sheet to create a cut. This method offers precision and the ability to produce complex shapes and designs. It is commonly used for prototypes or small production runs. When selecting the appropriate method for cutting aluminum sheet, factors to consider include desired cut quality, design complexity, material thickness, and production volume.

- Q:Can the aluminum sheets be used for reflector applications?

- Yes, aluminum sheets can be used for reflector applications. Aluminum is widely known for its high reflectivity, making it an ideal material for reflectors in various industries. It has a reflectivity of around 90% for visible light and up to 95% for infrared radiation. The smooth surface of aluminum sheets allows for efficient reflection of light and heat, making them suitable for applications such as automotive headlights, solar reflectors, lighting fixtures, and optical instruments. Additionally, aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, further enhancing its suitability for reflector applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bar Checkered Aluminium Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords