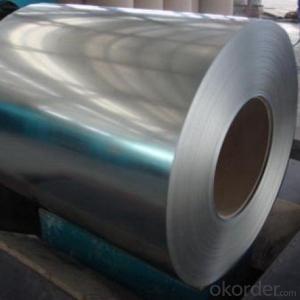

Hot Rolled Stainless Steel Coils NO.1 Finish Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q:Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for outdoor use. It is resistant to rust and can withstand various weather conditions, including rain, snow, and high humidity. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for outdoor furniture and fixtures. It is often used in the construction of outdoor tables, chairs, benches, grills, and other fixtures due to its strength, longevity, and resistance to environmental factors.

- Q:What does "stainless steel plate" 6.0*1500c mean?

- 1500 can be expressed as stainless steel width.Usually, the Rongchang self lubrication stainless steel plate is expressed in this way. The Rongchang self lubricating stainless steel plate is made up of 3 layers

- Q:What's the difference between stainless steel 304 and stainless steel 202?

- Different chemical composition. 304 of the nickel is much higher than 202.

- Q:What are the applications of stainless steel sheets?

- Due to their various beneficial properties, stainless steel sheets find a wide range of applications. Some common uses include: 1. Construction: Stainless steel sheets are widely utilized in the construction industry for various purposes. They provide durability, corrosion resistance, and an attractive appearance, making them suitable for cladding, roofing, wall panels, as well as structural components like beams, columns, and reinforcement bars. 2. Kitchenware: The production of kitchen appliances and utensils extensively involves stainless steel sheets. They are used to manufacture sinks, countertops, backsplashes, and cabinets. Stainless steel is preferred in the kitchen due to its hygienic properties, resistance to staining and corrosion, and ease of cleaning. 3. Automotive industry: Stainless steel sheets are utilized in the automotive industry for producing various components. They are used in the manufacturing of exhaust systems, mufflers, fuel tanks, and decorative trims. Stainless steel sheets offer corrosion resistance, heat resistance, and durability in harsh automotive environments. 4. Medical equipment: The medical field widely employs stainless steel sheets for the production of surgical instruments, implants, and medical equipment. The corrosion resistance and biocompatibility of stainless steel make it an ideal material for these applications. 5. Chemical processing: The chemical industry heavily relies on stainless steel sheets due to their corrosion resistance and ability to withstand high temperatures. They are used for manufacturing storage tanks, pipes, valves, and pressure vessels. Stainless steel sheets are preferred in chemical processing applications to prevent contamination and ensure process safety. 6. Energy and power generation: Stainless steel sheets are utilized in power plants, refineries, and other energy generation facilities. They are used in manufacturing boilers, heat exchangers, and condensers due to their high-temperature resistance, corrosion resistance, and strength. 7. Decorative applications: Stainless steel sheets are frequently employed in architectural and decorative applications. They are used for decorative panels, elevator doors, signage, and furniture. The versatility of stainless steel allows for various finishes and textures, making it a popular choice in interior and exterior design. In conclusion, stainless steel sheets are incredibly versatile and find numerous applications in various industries. Their corrosion resistance, durability, strength, and aesthetic appeal make them an ideal material for a wide range of purposes.

- Q:What are the different types of edge finishes for stainless steel sheets?

- There are several different types of edge finishes that can be applied to stainless steel sheets. These finishes are designed to enhance the appearance and functionality of the edges while also providing protection against corrosion and damage. 1. Mill Finish: This is the most basic type of edge finish, where the edges are left as they come from the mill. It is a straight, unfinished edge without any additional treatment or polishing. 2. Deburred Edge: In this type of finish, the rough edges are smoothed out and deburred using abrasive materials. This helps to eliminate sharp edges and burrs, making the sheet safer to handle and preventing potential injuries. 3. Rounded Edge: A rounded edge finish involves milling or machining the edges to create a curved or rounded profile. This type of finish is commonly used in applications where safety is a concern, as it reduces the risk of cuts or injuries caused by sharp edges. 4. Beveled Edge: A beveled edge finish involves cutting or grinding the edges at an angle to create a sloped or chamfered profile. This type of finish is often used for aesthetic purposes, as it adds a decorative element to the sheet and can create a smooth transition between different surfaces. 5. Polished Edge: In this type of finish, the edges of the stainless steel sheet are polished to a high shine using abrasive materials or polishing compounds. This produces a smooth, reflective surface that enhances the overall appearance of the sheet and gives it a more finished look. 6. Brushed Edge: A brushed edge finish involves applying a brushed texture to the edges of the stainless steel sheet. This is achieved by using abrasive materials or brushes to create a consistent pattern of fine lines or scratches. The brushed edge finish can provide a unique and contemporary look to the sheet. These different types of edge finishes for stainless steel sheets offer various benefits and can be chosen based on the specific requirements of the application. Whether it's for safety, aesthetics, or functionality, selecting the right edge finish can greatly enhance the performance and visual appeal of stainless steel sheets.

- Q:Can stainless steel sheets be used for elevator panels?

- Indeed, elevator panels can make use of stainless steel sheets. Stainless steel, being highly durable, strong, and visually appealing, is a favored material for elevator panels. Its resistance to corrosion, damage, and wear makes it ideal for high-traffic regions such as elevators. Furthermore, stainless steel panels are effortless to clean and maintain, which is crucial for preserving a pristine and polished appearance within elevators. Moreover, stainless steel can be easily tailored and manufactured to suit precise elevator dimensions and design necessities. All in all, stainless steel sheets represent a dependable and adaptable choice for elevator panels.

- Q:How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, it is important to clean them regularly using mild soap or detergent and water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Additionally, wipe down the sheets with a soft cloth to remove any fingerprints or smudges. Applying a thin layer of stainless steel cleaner or polish can help maintain the shine and protect against stains. It is also recommended to avoid exposure to harsh chemicals or acidic substances, as they can cause discoloration.

- Q:Are stainless steel sheets resistant to erosion corrosion?

- Yes, stainless steel sheets are highly resistant to erosion corrosion. This is primarily due to the presence of chromium in the alloy, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion. Furthermore, stainless steel sheets are also resistant to erosion corrosion caused by various chemicals and acids. The alloy composition of stainless steel, which typically includes elements such as nickel and molybdenum, enhances its resistance to corrosion in harsh environments. This makes stainless steel sheets suitable for a wide range of applications, including in industries such as chemical processing, oil and gas, and marine. However, it is important to note that the resistance of stainless steel sheets to erosion corrosion can vary depending on the specific grade or alloy used. Different grades may have different levels of corrosion resistance, so it is essential to choose the appropriate grade based on the specific environmental conditions and requirements of the application. Regular maintenance and proper handling can also help prolong the lifespan and maintain the corrosion resistance of stainless steel sheets.

- Q:What's the price of 06cr19ni10 and 304 stainless steel?

- In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 16% chromium, more than 8% of the nickel content. 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states.

- Q:Can stainless steel sheets be used for medical implants?

- Medical implants can indeed utilize stainless steel sheets. In the medical realm, stainless steel is frequently employed due to its remarkable resistance to corrosion, its strength, and its affordability. It is also biocompatible, meaning that it does not provoke any undesirable reactions when in contact with bodily tissues or fluids. To meet the distinct demands of medical implants, such as orthopedic plates, bone screws, dental implants, and cardiovascular stents, stainless steel sheets can be manufactured into a variety of shapes and sizes. Furthermore, stainless steel is easily cleanable and sterilizable, rendering it well-suited for implantation within the human body. However, it is important to note that different grades of stainless steel may possess varying attributes. As a result, it is crucial to choose the appropriate grade based on the specific application and requirements of the medical implant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel Coils NO.1 Finish Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords