Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

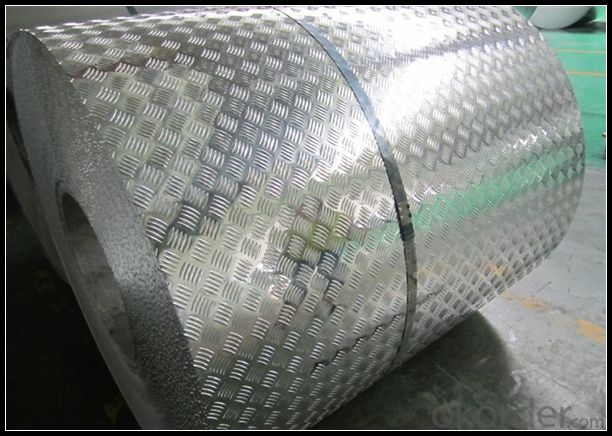

1. Specification of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Diamond, Stucco ,Bars etc |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

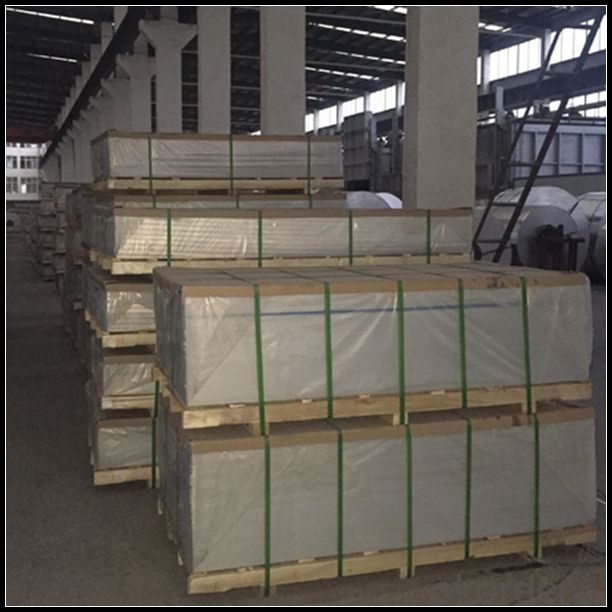

5. Image of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

6. Package and shipping of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- no that wouldn't make you sick. i line all my pans with foil before baking because it makes it much easier to clean the pans.

- Q:Can the aluminum sheets be used for manufacturing chemical piping systems?

- Indeed, the utilization of aluminum sheets in the production of chemical piping systems is plausible. Renowned for its remarkable resistance against corrosion, aluminum proves to be apt for handling an array of chemicals. Moreover, its lightweight nature facilitates effortless installation and maintenance procedures. Furthermore, aluminum possesses commendable thermal conductivity, thereby enabling efficient heat transfer within chemical processes. Nonetheless, it is crucial to contemplate the distinctive demands imposed by the chemicals being conveyed and seek guidance from specialists to guarantee the selection of aluminum sheets equipped with indispensable properties and compatibility with the chemicals to be employed within the piping system.

- Q:What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q:how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q:What are the different types of coatings available for aluminum sheets?

- There are various types of coatings available for aluminum sheets, including anodized coatings, paint coatings, powder coatings, and laminated coatings.

- Q:I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- If the material is right may be burned, a full air bubble is parts of the surface, whether the intergranular cracking section, part to do see the metallographic analysis of grain size, lower furnace installed furnace capacity amount control too much away from the direction of the thermocouple parts temperature indicator indicates the temperature to the temperature time lag of thermocouple thermocouple has high temperature parts away from the direction. 510 is enough to regularly test the stove uniformity and precision with 2 kinds of stove fan check

- Q:Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Automotive fuel tanks can be effectively manufactured using aluminum sheets. This material is preferred due to its exceptional characteristics, including its lightweight nature, durability, resistance to corrosion, and high strength-to-weight ratio. These properties make aluminum sheets highly suitable for the production of automotive fuel tanks, as they enable fuel efficiency, reduce the weight of vehicles, and enhance overall performance. Furthermore, aluminum sheets can be easily molded and joined through welding, allowing automotive manufacturers to create intricate tank designs while maintaining the tank's structural integrity. Moreover, the low melting point of aluminum sheets facilitates the welding process during tank manufacturing. In conclusion, the utilization of aluminum sheets in the manufacturing of automotive fuel tanks presents a reliable choice that adheres to safety standards and contributes to the efficiency and performance of vehicles.

- Q:Can aluminum sheets be used in aerospace industries?

- Aluminum sheets find frequent usage in aerospace industries. Lightweight and resistant to corrosion, aluminum proves to be an exceptional material with a remarkable strength-to-weight ratio, making it well-suited for diverse aerospace applications. Its capability to withstand elevated stress and pressure renders it valuable in the construction of aircraft structures, including wings, fuselage, and landing gear. Moreover, aluminum sheets possess malleability, allowing for the creation of intricate shapes that contribute to the requisite design flexibility within the aerospace sector. However, it is worth noting that aluminum alloys, rather than pure aluminum, are typically employed in aerospace applications due to their augmented mechanical properties and superior performance.

- Q:Can the aluminum sheets be used for manufacturing heat sinks?

- Aluminum sheets are capable of being utilized in the production of heat sinks. Owing to its exceptional thermal conductivity features, aluminum is a favored option for heat sinks. It possesses lightweight properties, exhibits high electrical conductivity, and can be easily machined, rendering it an ideal substance for dissipating heat from electronic components. The malleability of aluminum sheets permits them to be effortlessly shaped, cut, and molded into the desired heat sink design, facilitating effective heat transfer and dissipation. Furthermore, aluminum is resistant to corrosion, which guarantees the enduring and dependable performance of the heat sink. In summary, aluminum sheets are widely employed in the manufacturing of heat sinks for a variety of applications across industries such as electronics, automotive, and aerospace.

- Q:What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords