304 Stainless Steel Sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

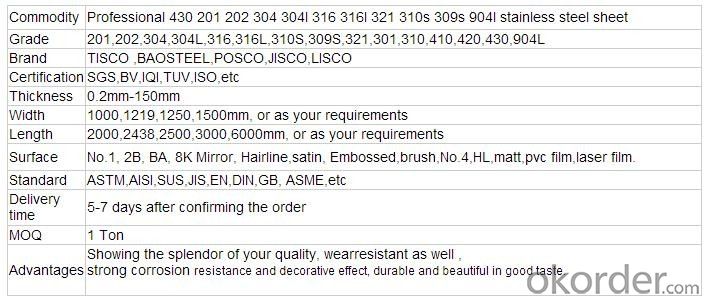

Item specifice

304 stainless steel sheet with competitive price

Product Photos

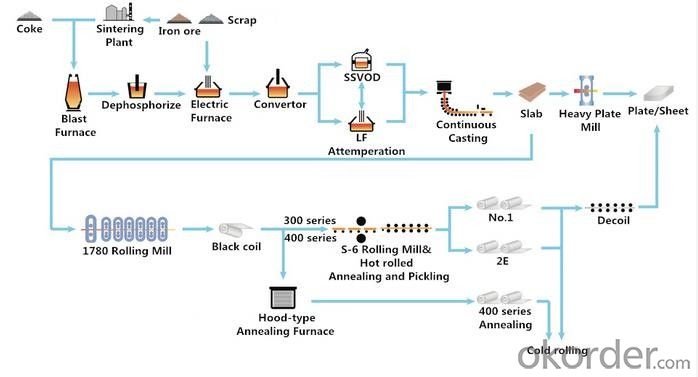

Production Flow

Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff

Product Uses

Application--stainless steel sheet/plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas – platform accommodation, cable trays, subsea pipelines.

4.Medical – Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General – springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical – pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports.

Related Products

Related Product:

Our Services

Services:

1.Sample:Free samples will be available for most of the products, but usually the freight ,charges need to paid by your side.

2.Inquiry:24 hours online to ensure your inquiry will be replied within 12 hours .

3.Delivery:Most products can be delivered within 7 days after order.

4.Small order also can be accepted.

Why Choose

1. We have professional export team.

2.We can provide Mill test certificate.

3.we cooprationwith more than 20 countries.

4.wu have good service&short delivery time.

5.we can provide free sample for your evalution.

6.All products are made of high-quality stainless steel sheet.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

Package--wooden pallets without fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

We warmly welcome clients from all over the world to cooperate with us and develop worldwide market together. Also we hope we can have chance to establish longterm business relationship with you on the basis of mutual benefits!

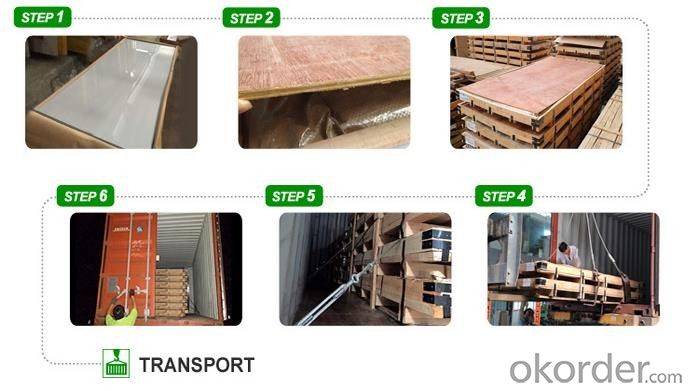

Packaging & Shipping

1 Sheets covered with wooden plate for protection in transportation.

2. All sheets will be loaded in strong wooden packages.

3. Every cartons loaded with good shoring and strengthening.

4. Take container loading pictures and seal the container.

5. Transportation speed is quick. And keep customer each step informed.

- Laser PVC: Poli-film, Novancel

- 70 /100 Micron Laser PVC

- Single/Double 70 Micron Black&white PVC.

- Q:Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel toughness better: 201 stainless steel material is relatively hard, with a little steel, relatively easy to crack. The 304 stainless steel insulation Cup because it contains nickel, it is not rusty, and 304 stainless steel more toughness, fatigue resistance is much better than 201.

- Q:How do I prevent fingerprints or smudges on stainless steel sheets?

- To avoid the presence of fingerprints or smudges on stainless steel sheets, there are several simple steps that can be taken: 1. Regularly clean the surface: Regularly wiping the stainless steel sheets with a soft cloth or microfiber cloth can help prevent the accumulation of fingerprints and smudges. 2. Utilize mild soap and water: Create a mixture of warm water and a few drops of mild dish soap. Dip the cloth into this solution and gently wipe the stainless steel surface in the direction of the grain. This will eliminate any dirt or oil that may attract fingerprints. 3. Thoroughly dry: After cleaning, ensure that the stainless steel sheets are completely dry by using a clean, dry cloth. This will prevent the occurrence of water spots or streaks that can give the surface a smudged appearance. 4. Avoid abrasive cleaning agents or tools: Refrain from using harsh chemicals, abrasive cleaners, or scrub brushes as they can harm the stainless steel finish, making it more susceptible to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths in order to preserve the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Applying a stainless steel cleaner or polish can establish a protective barrier on the surface, rendering it more resistant to fingerprints and smudges. Adhere to the instructions provided with the product and use a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you are aware that your hands tend to leave fingerprints easily, it may be beneficial to wear gloves while handling stainless steel sheets. This precautionary measure can prevent direct contact with the surface and diminish the likelihood of leaving smudges. By adhering to these suggestions, the cleanliness and luster of your stainless steel sheets can be maintained, thereby preventing fingerprints and smudges from diminishing their appearance.

- Q:What are the different types of stainless steel sheet surface textures available?

- There are several different types of stainless steel sheet surface textures available, each with its own unique aesthetic appeal and functional properties. Some of the most common surface textures include: 1. No.1 Finish: This is the most common and widely used surface finish for stainless steel sheets. It has a smooth, reflective surface that is achieved by hot rolling the steel and then annealing it. 2. No.2B Finish: This finish has a slightly rougher texture compared to No.1 finish. It is achieved by cold rolling the steel and then annealing it, resulting in a dull, matte appearance. 3. No.4 Finish: Also known as satin or brushed finish, this surface texture has a fine grain appearance with short, parallel lines. It is achieved by polishing the surface with abrasive belts or brushes. 4. Hairline Finish: This surface texture is similar to No.4 finish but has a finer grain appearance. It is achieved by polishing the surface with abrasive belts or brushes in a unidirectional pattern. 5. No.8 Mirror Finish: This is the most reflective surface texture available for stainless steel sheets. It has a highly polished and mirror-like appearance, achieved by further polishing the surface after No.4 finish. 6. Bead Blasted Finish: This surface texture is achieved by blasting the stainless steel sheet with fine glass beads or ceramic particles. It results in a textured, non-reflective surface with a uniform matte appearance. 7. Embossed Finish: This surface texture involves imprinting a pattern or design onto the stainless steel sheet. It can be achieved through mechanical embossing or by using a special roller during the manufacturing process. 8. Colored Finishes: Stainless steel sheets can also be coated with various colors to enhance their visual appeal. These colored finishes are achieved through processes like PVD (Physical Vapor Deposition) or powder coating, resulting in a durable and vibrant surface. These are just some of the many surface textures available for stainless steel sheets, each offering its own distinct look and feel. The choice of the surface texture depends on the desired aesthetic, functional requirements, and the specific application of the stainless steel sheet.

- Q:Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for pool environments. It provides a sleek and modern aesthetic, and its resistance to rust and staining ensures longevity and ease of maintenance.

- Q:What are the different types of stainless steel sheet finishes for medical applications?

- There are several different types of stainless steel sheet finishes that are commonly used for medical applications. These finishes are designed to provide specific qualities and characteristics that are necessary for medical environments. One common finish is the 2B finish, which is a smooth, reflective finish that is achieved through a cold-rolling process. This finish is often used in medical equipment and instruments as it is easy to clean and has a high corrosion resistance. Another commonly used finish is the No. 4 finish, also known as a satin finish. This finish has a brushed appearance and is often used in medical cabinets and surfaces. It provides a good combination of aesthetics and functionality, as it is easy to clean and has good corrosion resistance. For more specialized applications, there are also finishes such as the No. 8 mirror finish. This finish is highly reflective and is often used in surgical instruments and other high-end medical equipment. It provides a visually appealing surface and has excellent corrosion resistance. In addition to these finishes, there are also other options such as the bead blast finish, which creates a matte surface with a textured appearance. This finish is often used for medical equipment that requires a non-reflective surface. Overall, the choice of stainless steel sheet finish for medical applications depends on the specific requirements of the equipment or surface. Each finish has its own advantages and characteristics, and it is important to select the appropriate finish to ensure the best performance and longevity in a medical environment.

- Q:What are the different types of finishes available for stainless steel sheets?

- There are several types of finishes available for stainless steel sheets, including mill finish, brushed finish, mirror finish, embossed finish, and patterned finish.

- Q:Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be used for automotive applications. Stainless steel is a highly versatile and durable material that offers excellent resistance to corrosion, heat, and impact. These properties make it ideal for automotive applications where durability and resistance to harsh environments are essential. Stainless steel sheets can be used in various parts of the automotive industry, including body panels, exhaust systems, fuel tanks, and even interior components. Additionally, stainless steel can be easily formed, welded, and manipulated to meet specific design requirements, making it a popular choice in the automotive industry.

- Q:Are stainless steel sheets suitable for water treatment facilities?

- Yes, stainless steel sheets are highly suitable for water treatment facilities. Stainless steel is known for its corrosion resistance, which is crucial in an environment where water and chemicals are constantly present. It is resistant to rust and degradation, ensuring the longevity and durability of the sheets. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for facilities that require regular hygiene and sanitation. The material is also highly resistant to heat and extreme temperatures, ensuring its performance even in demanding conditions. Moreover, stainless steel is non-reactive, meaning it does not release harmful substances into the water during treatment processes, making it safe and reliable for water treatment applications.

- Q:Can stainless steel sheets be used in decorative applications?

- Yes, stainless steel sheets can be used in decorative applications. Due to their durability, versatility, and attractive appearance, stainless steel sheets are commonly used in interior and exterior design projects, such as wall cladding, decorative panels, countertops, backsplashes, and furniture. They offer a sleek and modern aesthetic while also being resistant to corrosion, making them suitable for both functional and decorative purposes.

- Q:What is the difference between hot rolled and cold rolled stainless steel sheets?

- The main difference between hot rolled and cold rolled stainless steel sheets lies in the manufacturing process. Hot rolled stainless steel sheets are produced by heating a stainless steel slab above its recrystallization temperature and then rolling it through a series of rollers to achieve the desired thickness. This process results in a rougher surface finish and can sometimes lead to a slight curvature in the sheets. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then passing them through a set of rollers at room temperature. This process creates sheets with a smoother surface finish and precise dimensions. Cold rolling also increases the strength and hardness of the stainless steel. In summary, hot rolled stainless steel sheets have a rougher surface finish and may exhibit slight curvatures, while cold rolled stainless steel sheets have a smoother surface finish and are more precise in their dimensions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords