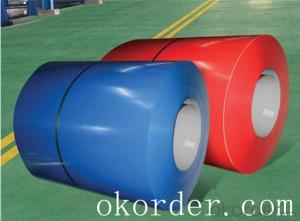

Prime quality prepainted galvanized steel 635mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

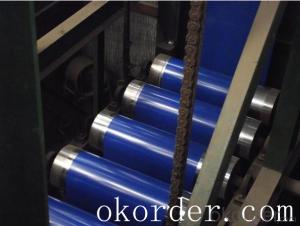

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q:How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q:Are steel billets used in the production of sporting goods?

- Yes, steel billets are commonly used in the production of sporting goods. They are often utilized to create various components such as the shafts of golf clubs or the frames of bicycles. Steel billets provide durability and strength to these sporting goods, making them suitable for intense physical activity.

- Q:What are the main factors affecting the thermal expansion of steel billets?

- The main factors affecting the thermal expansion of steel billets include temperature, composition of the steel, and the grain structure of the material.

- Q:How are steel billets used in the production of conveyor systems?

- Steel billets play a crucial role in the production of conveyor systems, as they are utilized to form the main structural framework. To achieve the desired shape, the billets undergo a process called hot rolling, which involves heating them and passing them through a series of rollers. This results in the transformation of the billets into long, slender bars with a consistent cross-sectional shape. Once shaped, the steel billets are further processed to create various components for the conveyor system. These components include conveyor frames, support beams, brackets, and other structural elements that provide stability and strength to the system. Steel billets are well-suited for this purpose due to their high tensile strength and durability. Apart from structural components, steel billets are also utilized in the production of conveyor rollers. These rollers are essential for facilitating the movement of materials along the conveyor system. The steel billets are machined and formed into cylindrical shapes, which are then fitted with bearings to ensure smooth rotation. The rollers are then installed at regular intervals along the conveyor, enabling efficient and continuous material handling. Furthermore, steel billets are often employed in the manufacturing of conveyor belts. The billets are processed into thin sheets, which are then coated with materials such as rubber or fabric to provide grip and durability. These belts bear the load of the materials being transported and are designed to withstand heavy usage and harsh environments. In conclusion, steel billets are vital in the production of conveyor systems, providing essential structural support as well as components like rollers and belts. Their strength, durability, and versatility make them an ideal choice for constructing conveyor systems that can handle heavy loads and ensure efficient material handling in various industries.

- Q:Are there any alternative materials to steel billets in certain applications?

- Yes, there are several alternative materials to steel billets in certain applications. Some of these alternative materials include: 1. Aluminum: Aluminum is a lightweight and corrosion-resistant material that is commonly used as an alternative to steel in applications where weight reduction is important, such as in the aerospace industry. 2. Copper: Copper is a ductile and highly conductive material that is often used in electrical and plumbing applications. It is an alternative to steel billets in applications where high electrical conductivity is required. 3. Titanium: Titanium is a lightweight and high-strength material that is commonly used in applications that require both strength and corrosion resistance, such as in the automotive and aerospace industries. 4. Composite materials: Composite materials, such as carbon fiber reinforced polymers, are increasingly being used as alternatives to steel in applications where weight reduction and high strength are critical, such as in the construction of aircraft and high-performance sports equipment. 5. Plastic: Some applications that do not require high strength or durability can use plastic as an alternative material to steel billets. Plastic is lightweight, cost-effective, and can be easily molded into various shapes. It is important to consider the specific requirements of each application when choosing an alternative material to steel billets, as each material has its own unique properties and limitations.

- Q:Can steel billets be used in the production of railway infrastructure?

- Yes, steel billets can be used in the production of railway infrastructure. Steel billets are semi-finished steel products that can be further processed into various railway components such as rails, sleepers, and fasteners. Due to their high strength, durability, and ability to withstand heavy loads and harsh environmental conditions, steel billets are commonly used in the manufacturing of railway infrastructure to ensure the safety and efficiency of train operations.

- Q:How are steel billets inspected for dimensional accuracy?

- Steel billets are inspected for dimensional accuracy through a series of rigorous processes to ensure that they meet the required specifications. These inspections are crucial as any deviations in the dimensions can have a significant impact on the final product's quality and performance. Firstly, steel billets are visually inspected to identify any surface defects or irregularities. This includes checking for cracks, surface oxidation, or any other visible abnormalities that could affect the dimensions. This visual inspection is often conducted by trained personnel who have an eye for detail and can identify even the smallest imperfections. After the visual inspection, the billets undergo dimensional measurement using various tools and instruments. One commonly used tool is a caliper, which is used to measure the length, width, and height of the billet. The measurements are compared against the specified dimensions to ensure they fall within the acceptable range. Any deviations beyond the tolerance limit are flagged for further investigation. In addition to calipers, other tools such as micrometers, height gauges, and coordinate measuring machines (CMM) may also be used to measure specific dimensions or features of the billet. These instruments provide more accurate and precise measurements, especially for critical dimensions that require a higher level of precision. Furthermore, non-destructive testing techniques are employed to assess the internal quality and dimensional accuracy of the billets. Ultrasonic testing, for instance, uses high-frequency sound waves to detect any internal defects or inconsistencies that may affect the dimensions. This method can identify hidden flaws such as voids, inclusions, or discontinuities, providing a comprehensive assessment of the billet's dimensional accuracy. Overall, steel billets are inspected for dimensional accuracy through a combination of visual inspections, dimensional measurements using various tools, and non-destructive testing techniques. By conducting these inspections, manufacturers ensure that the billets meet the required specifications, leading to high-quality final products.

- Q:Can steel billets be used in the manufacturing of machinery?

- Steel billets have the capability to be utilized in the production of machinery. These semi-finished metal products are typically either hot rolled or forged into various shapes, such as bars, rods, or sheets. Machinery components like gears, shafts, bearings, and structural frames are manufactured using these billets as the raw material. The utilization of steel billets in machinery manufacturing offers numerous benefits. Steel is renowned for its exceptional strength, durability, and resistance to wear, making it a suitable choice for heavy-duty applications. Furthermore, steel can be easily machined, welded, and molded into intricate shapes, facilitating the production of complex machinery parts. Moreover, due to its high melting point and thermal conductivity, steel is an ideal material for applications involving high temperatures or requiring heat transfer. Overall, steel billets are extensively employed in machinery manufacturing due to their outstanding mechanical properties, versatility, and dependability.

- Q:What are the different types of steel billet quality control tests?

- There are several types of steel billet quality control tests, including dimensional checks, chemical composition analysis, surface inspection, mechanical property testing, and non-destructive testing.

- Q:What are the main disadvantages of using steel billets?

- There are several disadvantages associated with using steel billets in various industries. Firstly, one of the main drawbacks of steel billets is their high cost. Steel billets require a complex manufacturing process, involving melting and casting steel, which can be expensive. This cost is then transferred to the end product, making it less affordable for consumers. Secondly, steel billets tend to be heavy and bulky, making transportation and handling difficult. The weight and size of steel billets add to the overall logistical challenges in the supply chain, increasing costs and potentially causing delays. Another disadvantage is the limited availability of steel billets. Steel production requires a significant amount of resources and energy, and the availability of raw materials can be limited, leading to potential supply chain disruptions. This scarcity can negatively impact industries that rely heavily on steel billets for their operations. Furthermore, steel billets have limited shape flexibility. They are typically produced in standardized sizes and shapes, making it difficult to customize them for specific design requirements. This lack of flexibility can be a significant disadvantage in industries that require intricate and unique shapes for their products. Moreover, steel billets are prone to corrosion if not properly treated. The exposure to moisture and certain environments can cause rust and degradation, reducing the lifespan and durability of products made from steel billets. Regular maintenance and anti-corrosion treatments are essential to mitigate this disadvantage. Lastly, the production of steel billets has a significant environmental impact. The manufacturing process emits greenhouse gases and consumes large amounts of energy and water. These environmental concerns have led to increased scrutiny and regulations on steel production, adding additional costs and complexities to using steel billets. In conclusion, while steel billets have their advantages in terms of strength and durability, they also come with several drawbacks. These include high costs, transportation challenges, limited availability, lack of shape flexibility, susceptibility to corrosion, and environmental impact. It is crucial for industries to carefully consider these disadvantages when evaluating the use of steel billets in their operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime quality prepainted galvanized steel 635mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords