High Density Polyethylene Geocell with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

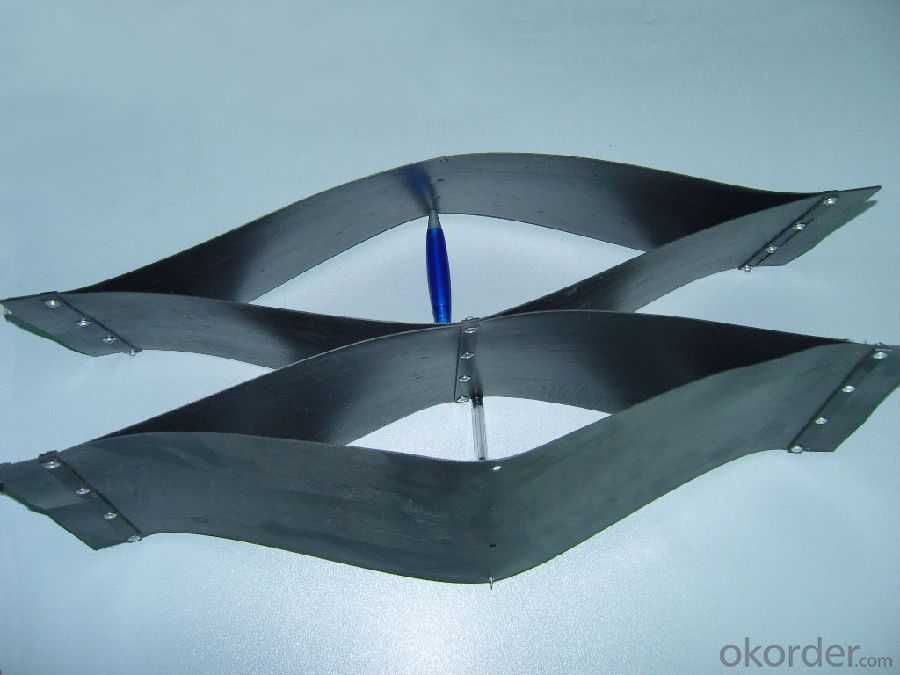

Description Of High Density Polyethylene Geocell:

Our geocell canbe made of PP/HDPE/plastic,

length:6.22m ;

thickness: 1-2mm

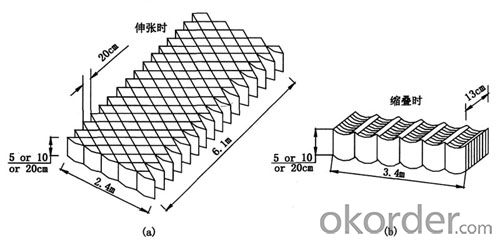

Geocell is a net-shaped cell structure made by welding high intensity thermoplastic sheet. It is flexible folded during service, and forming into struct with powerful lateral confinement and rigidity.

It can be used as cushion coat to strengthen loading capacity of weak ground or slope protection

structure, as well as stop structure, and so on.

Main Features of High Density Polyethylene Geocell:

1. Fix railway ground .

2. fix weak ground of roads .

3. block loading capacity.

4. treat river way of shallow water.

5. act as support in pipeline and sewer.

6. act as comprehensive block stopping land sliding and bearing loading capacity.

7. act as independent wall, dock and break-water.

8. treat desert, beach, riverbed and bank.

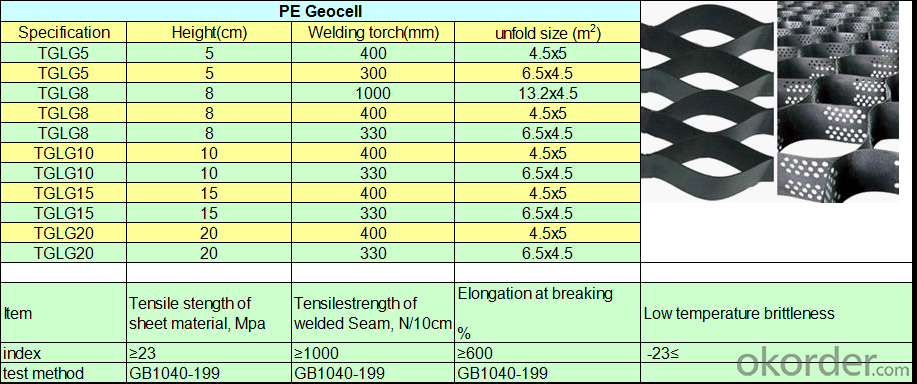

Specifications of High Density Polyethylene Geocell:

1.TGLG5 TGLG8 TGLG10 TGLG15 TGLG20(CM)

2.Stretch size :4mx5m or 6m x7m or at your request.

3. General roadbed reinforcement with 330 mm, 400 mm.

Slope protection with 500 mm, 660 mm

4.Executive standard:GB/T19274-2003

Technical specification of geocell

Applications of High Density Polyethylene Geocell:

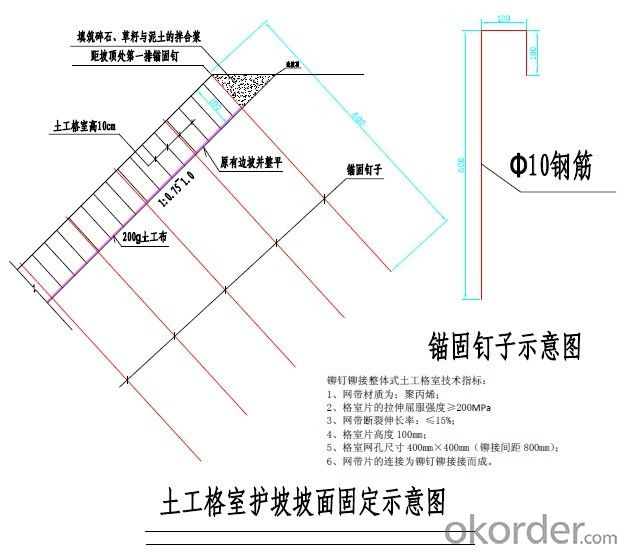

1. processing half fill Semi roadbed

build up the embankment on the ground on the slopes of the natural slope ACTS in 1:5, supporting subsoil should dig the steps, The step width shall be less than 1 m, when building or rebuilding roads widened by installments, Convergence between the new and old roadbed fill slope ,should dig the step, high grade highway width is 2 m, laid large geocell in each of the steps horizontally, using the large geocell of their own facade confining reinforcement effect, better solve the problem of uneven settlement

2. subgrade in wind drift sand region

Sand subgrade should be given priority to with low embankment, region filling height not less than 0.3 m. generally due to its low subgrade, sand subgrade construction in professional requirements and heavy load, adopting large chamber loose packing confining effect, can be in limited the height of the roadbed with high stiffness and strength, to inherit the load stress of large vehicles.

3. Reinforced back subgrade soil

Using large geocell can better achieve the goal of abutment back reinforced , can generate enough friction between the geocell and packing . and effectively reduce roadbed uneven subsidence, finally can effectively relieve the abutment jump car "disease early impact damage of bridge deck.

4. subgrade in permafrost region

In permafrost regions fill roadbed construction, should reach a minimum filling height in order to prevent or cause a frozen layer ceiling Frothing decreased, resulting in an excess of embankment settlement occurs. Geocell unique overall unconfined facades reinforced effect and effectively implemented, can ensure a minimum filling height in some special area to the maximum extent, and to fill a high-quality strength and stiffness.

5. The collapsibility loess roadbed treatment

When the highway and the highway collapse loess and loess lot better compression by wet, or foundation bearing capacity is lower than the high embankment to allow third-party vehicle load and weight of pressure embankment, subgrade bearing capacity requirements should also for processing, then the superiority of Geocell on manifest is no doubt.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What are the construction norms of composite geomembrane?

- The composite geomembrane construction process: One, base surface excavation, two, geomembrane pavement, three. align the welding seams, Four. welding, five. site inspection, Six , repair, seven,reinspection, eight, backfill soil

- Q:What are the techniques of foam concrete?

- With unique foam excitation technique, coal ash and other waste materials are mixed together in a scientific proportion, then they will become gold bricks—high-performance building blocks which can float on water with many advantages of lightweight, environmental protection, energy-saving and thermal insulation after going through many techniques of compulsory stirring, activation, foaming, output, casting molding. Special foaming agent is composed of several chemical raw materials in a certain proportion that are easy to buy. It will become light after foaming which is much more effective than that of most foaming agents sold in the market, but the price of it is 50% lower than that of most foaming agents sold in the market. High efficient curing agent is composed of several chemical raw materials in a certain proportion that are easy to buy, which greatly reduces cement quantity and cost. It has advantages of high strength and light weight, and enables non-autoclaved blocks (bricks) to reach and exceed the required strength of steam-cured blocks; MS innovative forming non-autoclaved blocks new molding technology, moulds can arbitrarily change the size of blocks in order to adapt to fit around the block sizes that walls need, which reduce the cost of moulds, and are convenient.

- Q:How do geomembranes contribute to protection of buried pipelines?

- Geomembranes contribute to the protection of buried pipelines by serving as a barrier between the pipeline and the surrounding soil or environment. They provide a protective layer that prevents the penetration of moisture, chemicals, or contaminants into the pipeline, reducing the risk of corrosion, leaks, or structural damage. Additionally, geomembranes can act as a cushioning material, absorbing and distributing external loads or stresses, thereby minimizing the potential for pipeline damage due to ground movement or settlement.

- Q:Why HDPE geomembrane(high density polyethylene geomembrane) is the most frequently used impermeable?material among artificial synthetic materials?

- Properties of HDPE geomembrane: ① excellent chemical resistance (corrosion resistance); ② outstanding ability of stress cracking resistance(ESCR); ③ low permeability; ④ excellent UV resistance; ⑤ stable low temperature vertical performance; The above is taken from Baidu Encyclopedia, there is another reason, the price is relatively more economical.

- Q:Can geomembranes be used for landfill capping?

- Yes, geomembranes can be used for landfill capping. Geomembranes are impermeable liners made from synthetic materials that can effectively contain and prevent the escape of waste materials in landfills. They are commonly used as a final cover system for landfill capping to provide a barrier against the infiltration of rainwater, leachate, and gas emissions, thus minimizing environmental impacts and protecting groundwater resources.

- Q:How to weld the geomembrane better?

- 1, the geomembrane should be extended from the bottom to the high position and should not be stretched too tight with 1.50% of height left in case of local subsidence. Considering the actual situation of the project, the side slope should be paved from top to bottom. 2, adjacent longtudinal joints should not be in a horizontal line and should be staggered over 1m. 3, longtudinal joints should be more than 1.50M away from dam toe and the corner of clubfoot and it should be put on the plane. 4, it should be laid at the side slope and then the bottom. 5, When the side slope is laid, the direction of the film should be parallel to the maximum gradient line.

- Q:is the graphite electrothermal?film useful?

- Generally speaking, the effect is good. One of its advantages is that the heating is fast, easy to control, and installation is not high. However, the heating effect and the degree of thermal insulation are related to the installation of electric heating film.

- Q:How to install the electrothermal?film?

- The installing method is as follows. After heat perservation measures are taken, the floor should be cleaned to be smooth and flat. Second, the aluminum foil reflective film should be laid flat and then the electrothermal?film should be laid. The electrothermal?film should be laid facing up. The Jiuzheng home furnishing net recommends that there should be a safe distance of about 20 cm between films. Then, tap wire is connected and the electrothermal?film is connected parallel to the wire. Both ends need insulating treatment. After the electrothermal?film is installed, the waterproof cloth can be covered on it as a waterproofing process.

- Q:What's the question need to notice about the construction method of composite geo-membrane?

- 1, construction preparation: 1) composite geomembrane materials quality testing, this project used composite geomembrane is two cloths film one film composite geo-membrane, 2) clean up embankment slope, flat ground, remove all sharp corner sundries, backfill and tamppile the slope is qualified acceptance after supervisor, providing working surface for the pavement of composite geo-membrane. 3) as for geomembrane split joint, for the sake of convenient construction, ensure the quality of split joint, composite geomembrane should as far as possible use wide range, decrease the field splice quantity , before construction, in accordance with the requirements of composite geomembrane width and scene length demands, it should be cut inside the unit, and spliced into the required size block, to roll it on the steel pipe, manual handling it to the working face. 2, 1) composite geomembrane pavement, 1) the laying method of composite geomembrane, compound geomembrane pavement is divided into paving of canal bed and slope paving two parts. Paving method: rolly paving it in axis direction of canal. slope paving, after qualified acceptance of slope, roll along the axis of the slope, and connect to composite geo-membrane in T-shape. 2) composite geo-membrane's pavement should be processed in dry and warm weather, in order to be convenient for split joint, prevent stress concentration, compound geomembrane pavement should take the wavy relaxation method, surplus degrees is about 1.5%, timely pull away after being open, and it requires that the composite geomembrane should be flat and smooth with slope surface, without ridges fold, construction personnel should wear flat soft cloth shoes or rubber shoes, it is forbidden to wear cleats, lest trampled geomembrane, if geomembrane is destroyed during construction, it should be repaired in a timely manner. 3) composite geo-membrane's split joint.

- Q:Are geomembranes suitable for use in oil refinery containment areas?

- Yes, geomembranes are suitable for use in oil refinery containment areas. Geomembranes are impermeable liners that can effectively contain and prevent the seepage of hazardous liquids, including oil, in containment areas. They are highly durable, chemically resistant, and can withstand the harsh conditions typically found in oil refinery environments. Additionally, geomembranes provide a cost-effective solution for oil spill containment and environmental protection in refinery facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Polyethylene Geocell with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords