Needle Punched Polyester Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Needle Punched Polyester Nonwoven Geotextile Fabric:

We have own lines to produce lower weight to 80gsm by needle punched, the main width is within 240cm or to 800cm:

Main Features of Needle Punched Polyester Nonwoven Geotextile Fabric:

1.100% pet

2.Width:58"

3.Basic weight: 80-500gsm

4.Color various

| material | 100% polyester |

| width | 58", or as customized |

| weight | 80gsm-500gsm |

| color | white color is mainly, other colors can provide accordingly |

| pattern | dyed |

| style | plain |

| nonwoven technics | Needle punched |

| feature | eco-friendly, anti-static, breathable, tear-resistant |

| application | widely used in the reinforcing, lamination material, hometextiel, packing, interlining, construction, filtering, mattress, etc. |

| payment | T/T or L/C |

Specifications of Needle Punched Polyester Nonwoven Geotextile Fabric:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

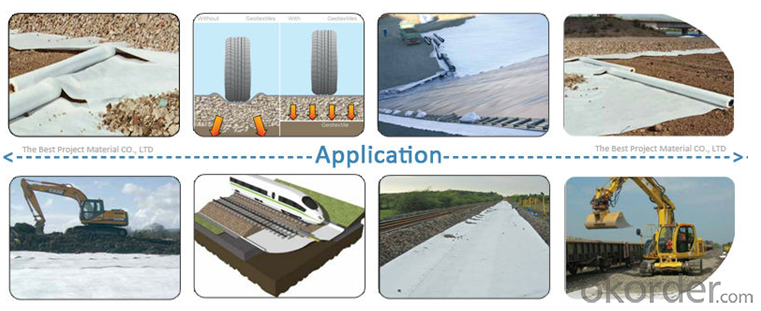

Applications of Needle Punched Polyester Nonwoven Geotextile Fabric:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Needle Punched Polyester Nonwoven Geotextile Fabric:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

- Q:Design of interlocking turf slope protection brick directly on the geotextile, river earth side by 1: 2.5 slope excavation, began laying geotextile, grass sand and gravel, can lay it? Geotextile laying on the grassroots what are the requirements? More

- No special requirements, mainly from the role of filtering, over the water, but I, specializing in the production of geotextile, geomembrane, wish smooth

- Q:What is the specific use of geotextile construction site? How much is it used?

- From the reinforcement, the role of filtration, I am specializing in the production of geotechnical materials

- Q:Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

- Q:Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q:What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q:What are the different manufacturing methods for geotextiles?

- There are several manufacturing methods for geotextiles, including needle punching, heat bonding, weaving, and knitting.

- Q:Neighborhoods: anti-seepage composite geotextile testing need to follow which test specifications, and routine testing items.

- There is a special GB ah GBT-1998 I was the production of geotechnical materials

- Q:What are the advantages of using geotextiles in green space development?

- There are several advantages of using geotextiles in green space development. Firstly, geotextiles help in soil stabilization by preventing erosion, which is crucial for the long-term sustainability of green spaces. Secondly, they improve water drainage and filtration, allowing for better moisture retention and reducing the risk of waterlogging. Additionally, geotextiles act as a barrier to weed growth, reducing the need for herbicides and manual maintenance. Lastly, they provide reinforcement and support to the soil, increasing its load-bearing capacity and enabling the development of structures like pathways and driveways. Overall, the use of geotextiles in green space development enhances the durability, functionality, and aesthetic appeal of these areas.

- Q:Can geotextiles be used in agricultural waste management systems?

- Yes, geotextiles can be used in agricultural waste management systems. Geotextiles are commonly used to control erosion, improve drainage, and provide filtration in various applications. In agricultural waste management, they can be utilized to line storage ponds, control the flow of water, and separate different layers of waste materials. Additionally, geotextiles can help in preventing nutrient leaching and protecting the surrounding environment from contamination.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Needle Punched Polyester Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords