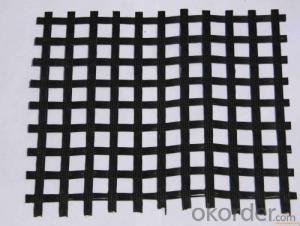

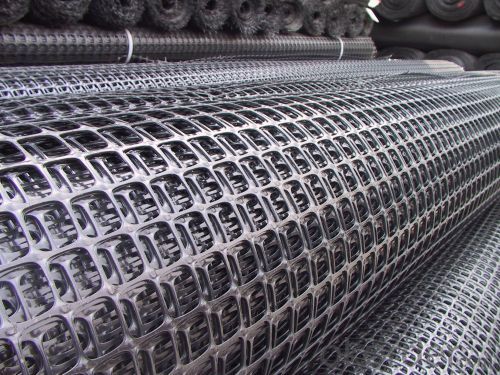

PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q:What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it influences the mechanical properties and performance of the geogrid material. Higher strain rates typically result in increased stiffness and strength, as well as reduced deformation and creep behavior. This is due to the time-dependent nature of geogrids, where faster loading rates induce a more immediate response from the material. Therefore, understanding and accounting for strain rate effects is crucial in designing and predicting the behavior of geogrids in various engineering applications.

- Q:Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids are commonly used in civil engineering and construction projects to enhance the stability and strength of soil structures. They can effectively distribute loads, reduce soil settlement, and improve overall performance of backfill materials. Therefore, geogrids are a reliable option for reinforcing bridge abutment backfills.

- Q:How much is a square meter

- 4, geogrid reinforced airport foundation can greatly improve the bearing capacity of the runway, to ensure the safety of aircraft landing5, geogrid can be used for garbage disposal, power plants, ash dam project, coal mine, metallurgy, green, enclosure and other fields6, the construction of soft foundation reinforcement, improve the overall bearing capacity of the foundation

- Q:How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional strength and stability. They act as a reinforcement material, distributing the forces and loads evenly throughout the structure. This helps to prevent soil erosion, slope failure, and settlement, ultimately enhancing the overall durability and longevity of the structure.

- Q:Do geogrids provide reinforcement to geosynthetic asphalt liners?

- Yes, geogrids provide reinforcement to geosynthetic asphalt liners. Geogrids are commonly used in combination with geosynthetic asphalt liners to enhance the structural integrity and load-bearing capacity of the liner system. They help distribute loads, reduce stress, and improve the overall performance of the asphalt liner.

- Q:How do geogrids improve the performance of geocell-reinforced embankments?

- Geogrids improve the performance of geocell-reinforced embankments by providing additional reinforcement and stability. They help distribute the load more evenly, reducing the stress on the geocells and preventing displacement or failure. Additionally, geogrids enhance the overall strength of the embankment, increasing its resistance to lateral movement and vertical settlement.

- Q:Geogrid specification TGSG40-40 what meaning

- I would like to tell you about, TGSG40-40: biaxial tensile plastic geogrid, the vertical and horizontal strength indicators are not less than 40KN, to meet the national standards.

- Q:What are the long-term performance monitoring requirements for geogrids?

- The long-term performance monitoring requirements for geogrids include regular inspections, assessment of durability and strength retention, measurement of creep and relaxation behavior, evaluation of long-term deformation and stability, and monitoring of the geogrid-soil interaction. Additionally, it is vital to monitor any potential degradation from environmental factors such as UV exposure, chemical exposure, and biological activity to ensure the geogrid's effectiveness over time.

- Q:What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific material and design of the geogrid. In general, higher temperatures can cause the geogrid to expand and become more flexible, which can result in increased tensile strength and improved load-bearing capacity. However, extreme temperatures, either high or low, can also lead to a decrease in geogrid properties, such as reduced stiffness and reduced resistance to deformation. Therefore, it is important to consider the temperature conditions in which the geogrid will be used to ensure optimal performance and longevity.

- Q:How do geogrids improve the performance of geocellular systems?

- Geogrids improve the performance of geocellular systems by providing reinforcement and structural stability. They help distribute load evenly, prevent lateral movement of soil, and enhance the overall strength of the system. Additionally, geogrids increase the bearing capacity of the geocells, reduce soil settlement, and improve drainage, thereby optimizing the performance and longevity of the geocellular system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords