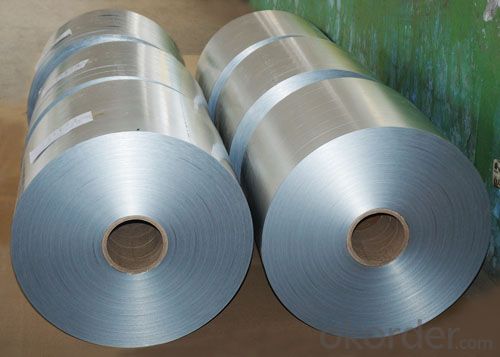

5052 Temper H32 0.8mm 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

5052 Temper H32 0.8mm 1mm Thick 1000mm Width Aluminum Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q:Aluminum roll 220 kg.0.3 thickness, 500 width, roll diameter is how much?

- You can use the outside diameter, the inner diameter and the width to get the volume. You know the density and volume, and then you can find the weight naturally

- Q:What should pay attention to transporting aluminum coil?

- You must ensure the good property of the aluminum coil.

- Q:Can aluminum coils be used for food processing equipment?

- Yes, aluminum coils can be used for food processing equipment. Aluminum is a popular material choice for its excellent heat transfer properties, corrosion resistance, and lightweight nature. It is commonly used in the construction of food processing equipment such as heat exchangers, evaporators, and condensers.

- Q:What is the weight of aluminum coils?

- The weight of aluminum coils can vary depending on their size and thickness. Generally, aluminum coils can range from a few hundred pounds to several thousand pounds in weight.

- Q:How do aluminum coils contribute to LEED certification requirements?

- Aluminum coils can contribute to LEED (Leadership in Energy and Environmental Design) certification requirements in several ways. First, aluminum is a highly sustainable material as it is 100% recyclable without any loss of quality. This means that using aluminum coils in construction projects can contribute to LEED credits for materials and resources, specifically in the category of recycled content. Additionally, aluminum coils are known for their energy efficiency properties. Aluminum is a lightweight material, which means less energy is required for transportation and installation compared to heavier alternatives. Furthermore, aluminum coils have excellent thermal conductivity, allowing for efficient heat transfer and reducing the energy consumption required for heating and cooling systems. These energy-saving benefits can contribute to LEED credits in the categories of energy and atmosphere. Moreover, aluminum coils have a long lifespan and require minimal maintenance. This durability reduces the need for frequent replacements and decreases waste generation. LEED recognizes the use of durable materials that promote longevity and reduce the environmental impact caused by constant replacements. Therefore, incorporating aluminum coils into a construction project can help earn LEED credits for sustainable sites and materials and resources. In conclusion, aluminum coils contribute to LEED certification requirements by offering high levels of recyclability, energy efficiency, and durability. Utilizing aluminum coils in construction projects can help achieve LEED credits in various categories, ultimately promoting sustainable and environmentally-friendly building practices.

- Q:How are aluminum coils used in the production of window frames?

- Aluminum coils are used in the production of window frames as they are shaped and formed into the desired profile using specialized machinery. These coils are first cut to the appropriate length and then fed through a series of rollers that shape them into the required dimensions for the window frame. The coils are then joined together and fastened to create the frame structure. The use of aluminum coils provides strength, durability, and corrosion resistance to the window frames, making them ideal for both residential and commercial applications.

- Q:How many 1220mm*2440mm aluminum sheets can one-ton aluminum coil be sliced to? Thank you.

- If it is 1.0mm thick, the coil can be sliced into 124 pieces. For other thickness, please use 124 divide the thickness.

- Q:How do aluminum coils contribute to reduced material waste?

- Aluminum coils contribute to reduced material waste in several ways. Firstly, aluminum is a highly recyclable material, meaning that it can be melted down and reused multiple times without losing its properties. This recyclability factor alone contributes to reducing material waste as it prevents the need for new aluminum extraction and production. Additionally, aluminum coils are often used in industries where precision and efficiency are crucial, such as in the manufacturing of automobiles, HVAC systems, and electrical equipment. These coils can be easily customized to meet specific requirements, minimizing the need for excess material and reducing waste. Furthermore, aluminum coils offer high strength-to-weight ratio, meaning that they can be manufactured using less material while still maintaining the desired strength and durability. This lightweight characteristic contributes to reduced material waste as it allows for more efficient transportation and installation processes, resulting in lower fuel consumption and less environmental impact. Moreover, aluminum coils can be designed for longer lifespan and improved corrosion resistance. This durability factor helps to minimize the frequency of replacement, reducing material waste over time. Additionally, the long lifespan of aluminum coils makes them an attractive choice for sustainable construction practices, further contributing to reduced waste in the long run. Overall, the use of aluminum coils in various industries not only promotes recycling and reusability but also enables efficient customization, lightweight construction, enhanced durability, and extended lifespan. These factors collectively contribute to reducing material waste and making aluminum coils an environmentally-friendly choice.

- Q:Can aluminum coils be used in food storage facilities?

- Aluminum coils are capable of being employed in food storage facilities. The food industry extensively employs aluminum due to its exceptional properties, including its lightweight nature, durability, resistance to corrosion, and effective heat conductivity. These attributes render aluminum coils suitable for a variety of applications within food storage facilities. Refrigeration systems, air conditioning units, and food storage cabinets are just a few examples of where aluminum coils can be utilized. Furthermore, aluminum is non-toxic and has no adverse reaction with food or its flavor, thus establishing it as a secure option for food storage. However, it is crucial to ensure that the aluminum coils used in food storage facilities undergo proper cleaning and maintenance to prevent any potential contamination.

- Q:How do aluminum coils contribute to the aesthetics of architectural designs?

- Architectural designs are significantly enhanced by the inclusion of aluminum coils, which offer a multitude of benefits. Firstly, their versatility in terms of shape and size is a key factor. This adaptability allows for the easy formation of aluminum coils into diverse shapes, making them suitable for a wide array of architectural applications. Moreover, the lightweight nature of aluminum coils contributes to their aesthetic appeal. When used in cladding or façade systems, they provide buildings with a sleek and modern appearance. This, in turn, adds a touch of elegance to the overall design, resulting in visually pleasing structures. Furthermore, aluminum coils offer a broad range of color options. Their coatability and ability to be painted provide architects and designers with an extensive palette of colors to choose from. This vast selection allows for the matching of a building's exterior with its surroundings or the creation of a specific mood or theme. The availability of various colors for aluminum coils opens up endless possibilities for customization and creativity in architectural design. Additionally, the durability and corrosion resistance of aluminum coils make them ideal for long-lasting architectural applications. They can withstand harsh weather conditions, ensuring that the building's aesthetics remain intact over time. This durability factor is crucial in maintaining the visual appeal of architectural designs, as it eliminates the need for frequent repairs or replacements. In conclusion, aluminum coils significantly contribute to the aesthetics of architectural designs due to their versatility, lightweight nature, color options, and durability. Their ability to be shaped into various forms, combined with a wide range of color choices, allows architects and designers to create visually stunning and customized buildings. The sleek and modern appearance of aluminum coils adds a touch of elegance to architectural designs, enhancing their overall aesthetics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5052 Temper H32 0.8mm 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords