Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Condition: New

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG 900S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Clamping Force: 9000kn

Power(W): 37+37

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Delivery Detail: | 60 DAYS |

|---|

| Description | Unit | LOG-900S8 | |||

| international recognized models | |||||

| injection | B | C | D | ||

| Tjeoretical injection volume | cm³ | 3179 | 3825 | 4750 | 5652 |

| Shot volume | g | 2893 | 3571 | 4321 | 5143 |

| Oz | 102.5 | 12.6 | 153 | 182.1 | |

| Screw diameter | mm | 90 | 100 | 110 | 120 |

| Injection diameter | mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 24.4:1 | 22:01 | 20:01 | 18.3:1 | |

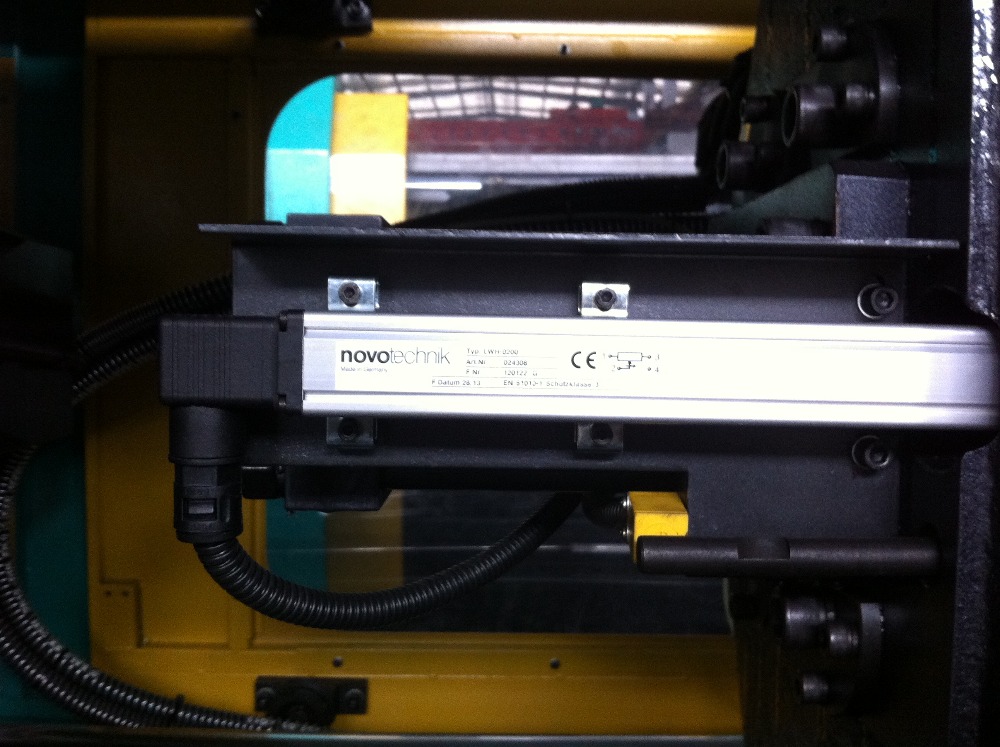

| Scerw steoke | mm | 500 | |||

| Screw rotate speed | r/min | 0-120 | |||

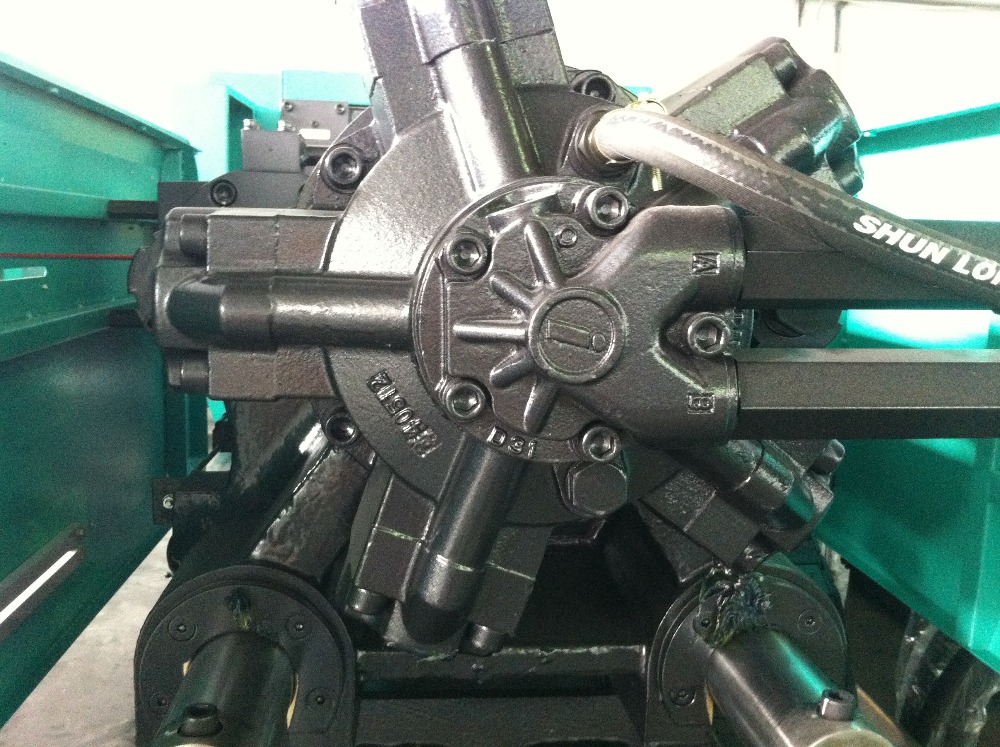

| CLAMPING UNIT | |||||

| Clamping force | kN | 9000 | |||

| Opening stroke | mm | 1050 | |||

| Platen size | mm*mm | 1530*1530 | |||

| Space between tie bars | mm*mm | 1080*1030 | |||

| Maldthickness | mm | 400-1100 | |||

| Platen Mix stroke | mm | 2150 | |||

| Ejection stroke | mm | 300 | |||

| Ejcetion force | kN | 270 | |||

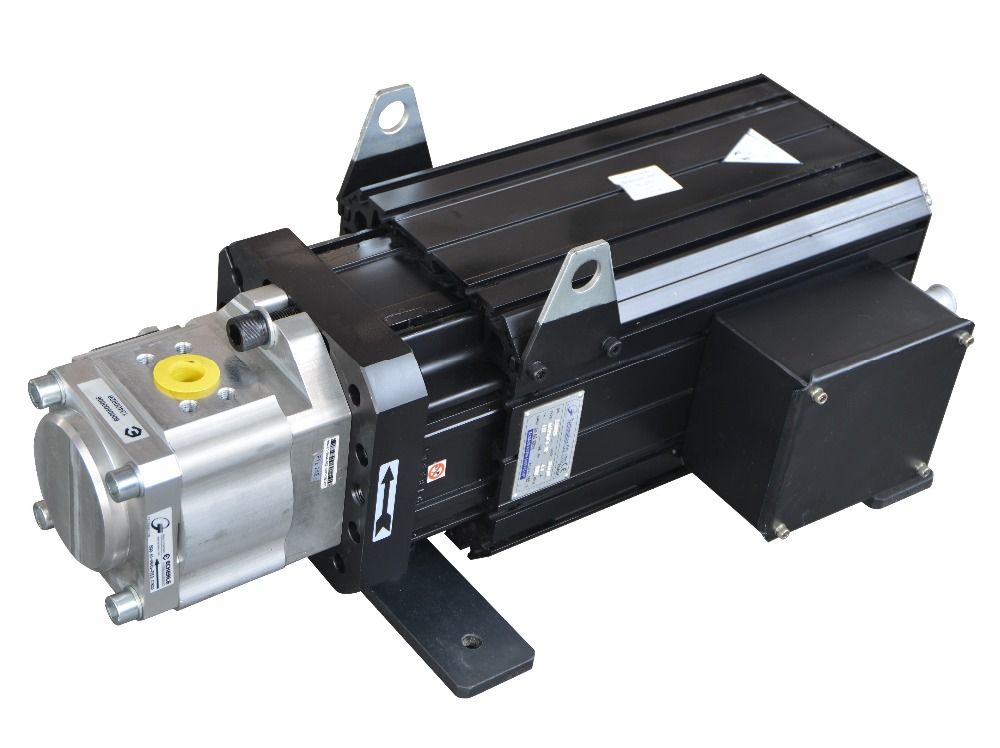

| Power/Elcetric Heating | |||||

| Hydralic system pressure | Mpa | 17.5 | |||

| Pump motor | kw | 37+37 | |||

| Heating power | kw | 52.45 | |||

| Number of temp.conteol | 6+nozzle | ||||

| Other | |||||

| Cycle time | sec | 8 | |||

| Tank volume | L | 1900 | |||

| Machine dimesions | m*m*m | 11*2.4*3.1 | |||

| Weight of machine | kg | 48000 | |||

- Q:Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- The injection time is not enough, the pressure of 50mm injection is not enough

- Q:Commissioning process of injection molding machine

- When we receive a set of moulds, we need to choose the machine according to the size of the mold, the clamping force and the size of the glue.Determine the type of machine before you enter the real tune. (the premise is that the machine is normal.)1. we first beer 10 beer water board plastic pieces (not go together -- about 95% of the full plastic glue), set the appropriate pressure to ensure that the actual pressure below the set (high pressure), starting from the highest rate of 99%, and then gradually reduce an amount equal to (10%) 10 plastic beer beer. - (constant pressure, rate of change of each separated by 10% to complete the 10 beer beer).2. record the filling time of each beer and the injection peak pressure.

- Q:How does the injection machine set up the die segments and the pressure and speed of each segment? Seek advice.

- Then enter the low voltage protection process.Low pressure process with 0 speed, 0 pressure for the best, special circumstances increased to less than 20%20bar. The distance is at the end of the starting point of the high voltage die.High voltage medium and low speed 40-60%, medium high voltage 60-100bar is appropriate. The starting position is the termination position of the die closing +3-5mm.Among them, the determination of the fast termination position and the low voltage termination position is particularly important.Speed and pressure focus on the smooth movement of the die without vibration. Special attention is paid to the setting method of low voltage protection.The above is personal experience, and I hope to help you.

- Q:Can polyurethane (PU) material be molded by injection molding machine?

- Polyurethane is divided into three categories, 1, thermosetting casting (CPU); 2, thermoplastic extrusion (TPU); 3, MPU (mixed type).TPU can be injected with an injection molding machine. CPU and MPU can't be injection molded.

- Q:Does the injection machine have to use cooling water?

- First, the injection molding machine normally work, it is necessary to cooling water.Two. Cooling water is related to the specific heat of molding material, the temperature and weight of melt and the temperature at the time of demoulding. The formula for the required ice water energy of a mold is Q=W * C * T * S. Among them:Q is the required ice water energy kcal / h;W for plastic raw material, weight kg / h;C is a plastic raw material with a specific heat of kcal / kg DEG c;T is the temperature difference between the temperature of the melt and the demoulding of the product;S is the safety factor (usually 1.35 - 2).When a single machine match, the general choice of small values, and when a cold water machine with a number of molds to match when the big value, such as the selection of air-cooled chillers, S should also be elected a big point.

- Q:What is low voltage protection (injection molding machine)?

- For example, when there is something on the surface of the mold to fit the mold, it will open the mold automatically in order not to damage the mold. This process is low voltage protection.

- Q:What is a vertical injection molding machine?

- Injection molding machine (referred to as injection machine or injection molding machine) is a thermoplastic or thermosetting material using plastic molding mold made of plastic products of all shapes of the main molding equipment.Injection molding is achieved by injection molding machines and moulds. Although many types of injection molding machine, but no matter what kind of injection molding machine, its basic function has two: (1) heating the plastic to reach the melting state; (2) exert high pressure on the molten plastic to make the shot full of mold cavity.Injection molding machine is usually composed of injection system, mould system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system and so on.Vertical injection molding machines for vertical injection, mostly under 3 tons

- Q:How to debug the injection molding machine? solve

- You ask too many questions, and debugging involves so many things. If you mean that a process problem is not clear, or you can do other debugging on the injection machine, you can write it out. Plastic injection is not difficult. As long as you are willing to learn, you will not succeed if you depend on it

- Q:Adjust the speed of injection molding machine screw speed is what role?

- Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q:How can the injection machine be set with parameters?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.Operation points:Before booting1. before the injection machine operation, check the electrical control box whether there is water, oil enter, if the electric equipment is wet, don't turn on the machine. The maintenance personnel should dry the electrical parts and then turn on the machine.2. before the injection machine operation, check whether the supply voltage is consistent, generally should not exceed 6%.3. check emergency stop switch, front and rear safety door switch is normal. Verify whether the motor and the pump rotate in the same direction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

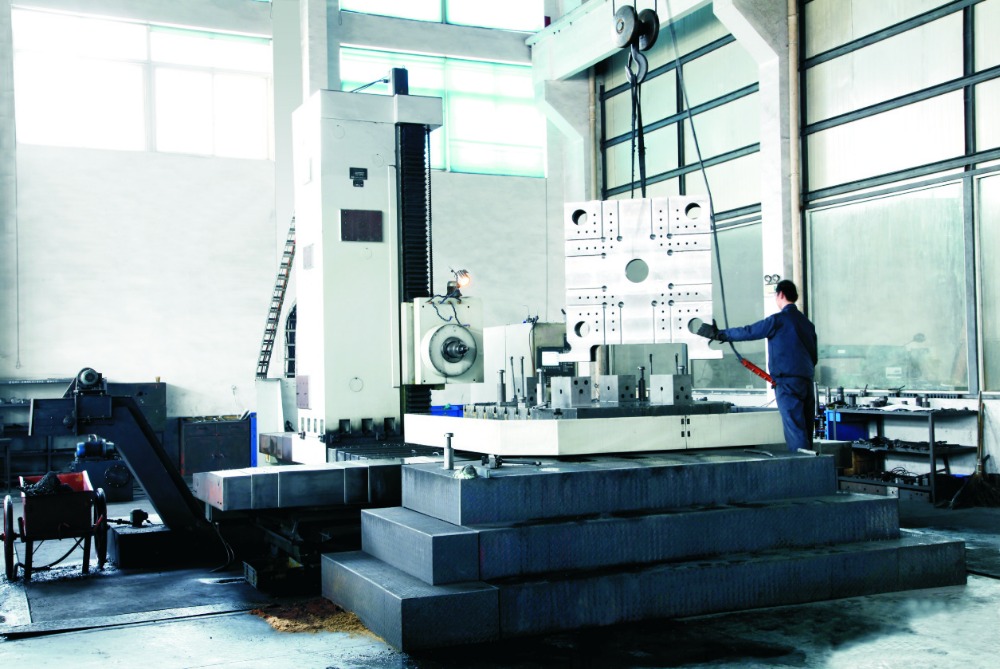

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords