304 Stainless Steel Sheet Direct sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

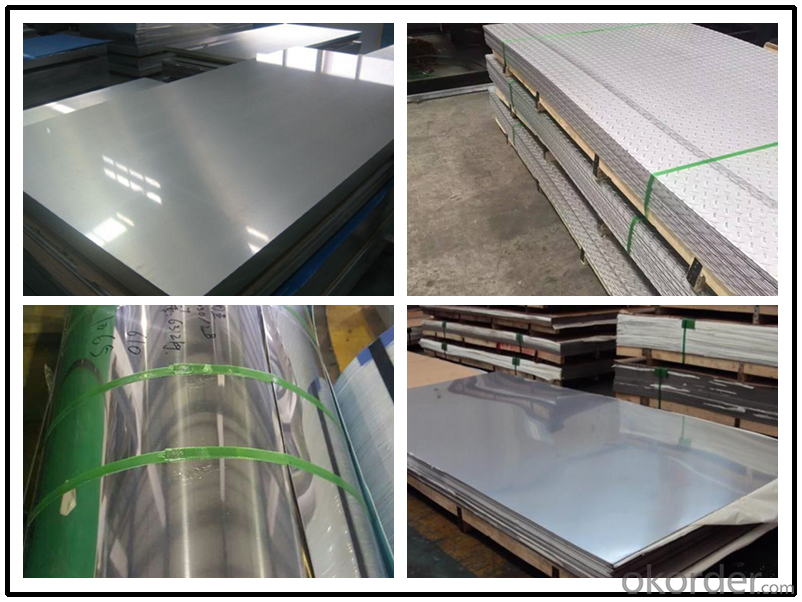

1. 304 Stainless steel sheet direct detailed introduction :

Description | 304 stainless steel sheet direct. |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made according to the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Detailed Images

Packaging & Shipping

Application

- Q:What does "stainless steel plate" 6.0*1500c mean?

- 1500 can be expressed as stainless steel width.Usually, the Rongchang self lubrication stainless steel plate is expressed in this way. The Rongchang self lubricating stainless steel plate is made up of 3 layers

- Q:How do you prevent distortion when welding stainless steel sheets?

- To prevent distortion when welding stainless steel sheets, one must ensure proper heat control and minimize the amount of heat input. This can be achieved by using a lower welding current and speed, employing a proper welding technique, and utilizing preheating or post-welding heat treatment methods if necessary. Additionally, using clamps or fixtures to hold the sheets in place during welding and distributing the heat evenly across the joint can also help prevent distortion.

- Q:Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a durable and versatile material that offers many advantages for façade applications. It is resistant to corrosion, weathering, and staining, making it an ideal choice for exterior use. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for a wide range of design options. Additionally, stainless steel can be finished in different ways, such as brushed, polished, or colored, providing further aesthetic possibilities. Its strength and rigidity also make it suitable for large-scale installations. Overall, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a popular choice for architectural façades.

- Q:Can stainless steel sheets be used for jewelry making?

- Yes, stainless steel sheets can be used for jewelry making. Stainless steel is a popular material for creating jewelry due to its durability, resistance to tarnishing, and hypoallergenic properties. It can be easily cut, shaped, and textured to create unique designs. Stainless steel sheets can be used to make various types of jewelry, including earrings, rings, bracelets, pendants, and even intricate chains. Additionally, stainless steel jewelry is often more affordable compared to precious metals like gold or silver, making it a popular choice for budget-conscious individuals or those looking for a more modern and industrial aesthetic.

- Q:How to clean stainless steel plate cleaning?

- If ordinary water leaves some dirt or grease, try adding a mild detergent to the water. The method I used was derived from natural, biodegradable detergent and found that it removed a little water and missed it, including some oils. If you clean stainless steel pots or cutlery, this is the best way to use them. The food on the cooked food can usually be removed from the pan, soaked in soapy water, and with a mild sponge sponge pad. Don't be impatient to use steel wool, it may scratch stainless steel or leave particles that may rust. Again, remember to rinse and dry the stainless steel after cleaning.

- Q:How do you prevent staining on stainless steel sheets?

- To prevent staining on stainless steel sheets, there are several measures you can take: 1. Regular cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using harsh chemicals or abrasive cleaners that can damage the surface. 2. Avoid exposure to corrosive substances: Keep stainless steel sheets away from corrosive substances such as bleach, ammonia, and acidic cleaners. If accidental spills occur, immediately rinse the affected area with water and thoroughly dry it. 3. Use a protective coating: Apply a protective coating or film on the stainless steel sheets to create a barrier between the surface and potential staining agents. There are various protective products available specifically designed for stainless steel, such as protective sprays or polishes. 4. Proper maintenance: Regularly inspect the stainless steel sheets for any signs of damage, scratches, or rust. Promptly address any issues by cleaning or repairing the affected areas to prevent staining. 5. Avoid abrasive materials: When cleaning or maintaining stainless steel sheets, use soft cloths or non-abrasive sponges to avoid scratching the surface. Avoid using steel wool or abrasive materials that can leave marks or damage the stainless steel. 6. Dry thoroughly: After cleaning the stainless steel sheets, ensure they are thoroughly dried to prevent water spots or mineral deposits from forming. Use a clean, lint-free cloth to wipe away any moisture. 7. Handle with care: Be mindful of how you handle stainless steel sheets to prevent scratching or damaging the surface. Avoid dragging or sliding heavy objects across the sheets, as this can leave marks or cause abrasions. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets and minimize the risk of staining.

- Q:What is the impact strength of stainless steel sheets?

- The impact strength of stainless steel sheets may vary based on several factors, including the grade and thickness of the stainless steel and the specific conditions under which the impact occurs. Stainless steel possesses inherent properties that contribute to its good level of impact strength, such as high tensile strength and ductility. Stainless steel is renowned for its ability to endure impacts and resist deformation, making it a favored material in industries where durability is crucial. It demonstrates exceptional resistance to impact loading, enabling it to withstand sudden impact forces without fracturing or breaking. Consequently, stainless steel sheets are well-suited for applications that demand high impact resistance, such as structural components, automotive parts, and machinery. Nevertheless, it is important to note that impact strengths may differ among various grades of stainless steel. Austenitic stainless steels (e.g., 304 and 316), for instance, exhibit excellent impact resistance due to their elevated nickel and chromium content. Conversely, ferritic and martensitic stainless steels may possess slightly lower impact strengths. Moreover, the thickness of the stainless steel sheet also influences its impact strength. Thicker sheets generally offer greater impact resistance compared to thinner ones, as they can absorb more energy before yielding or fracturing. It is worth mentioning that the impact strength of stainless steel can be further improved through additional methods, such as heat treatment and alloying. These processes enhance the material's toughness and resistance to impact loading. In conclusion, stainless steel sheets possess favorable impact strength that suits many applications. However, it is advisable to consult specific grade and thickness specifications, as well as any relevant industry standards or regulations, to determine the precise impact strength requirements for a particular application.

- Q:Can stainless steel sheets be embossed or textured?

- Yes, stainless steel sheets can be embossed or textured. This process involves imprinting patterns or designs onto the surface of the stainless steel sheets, adding visual interest and texture to the material.

- Q:How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps you can take: 1. Regular Cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals such as bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural cleaners like vinegar or lemon juice. 3. Proper Storage: Store stainless steel sheets in a clean and dry environment to avoid exposure to moisture or humidity. Moisture can lead to corrosion or rust, which can cause discoloration. If the sheets are stored outdoors, cover them properly to protect them from rain or snow. 4. Use Protective Coatings: Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available in the market specifically designed for stainless steel protection. Follow the manufacturer's instructions for application and reapplication, if necessary. 5. Avoid Contact with Reactive Metals: Avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. Ensure separation or isolation between stainless steel and reactive metals. 6. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If you notice any stubborn stains, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets, ensuring they remain free from discoloration or staining for an extended period.

- Q:Who knows the production process of stainless steel plate?

- Stainless steel surface process:Stainless steel has a variety of surface processing to broaden its application areas, different surface processing makes the surface of stainless steel different, making it unique in the application.The corrosion environment requires smooth surface for smooth surface is not easy to fouling. Deposition of dirt can make stainless steel rusty and even cause corrosion.In the spacious lobby, stainless steel is the most commonly used decorative materials for the elevator decoration, although the surface of the fingerprint can erase, but affect the appearance, it is best to use the appropriate surface to prevent leaving fingerprints.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Sheet Direct sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords