Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG130-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 196g-239g-277g

Clamping Force: 1300KN

Opening Stroke: 380mm

Power(W): 11 Kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Name: PET Preform

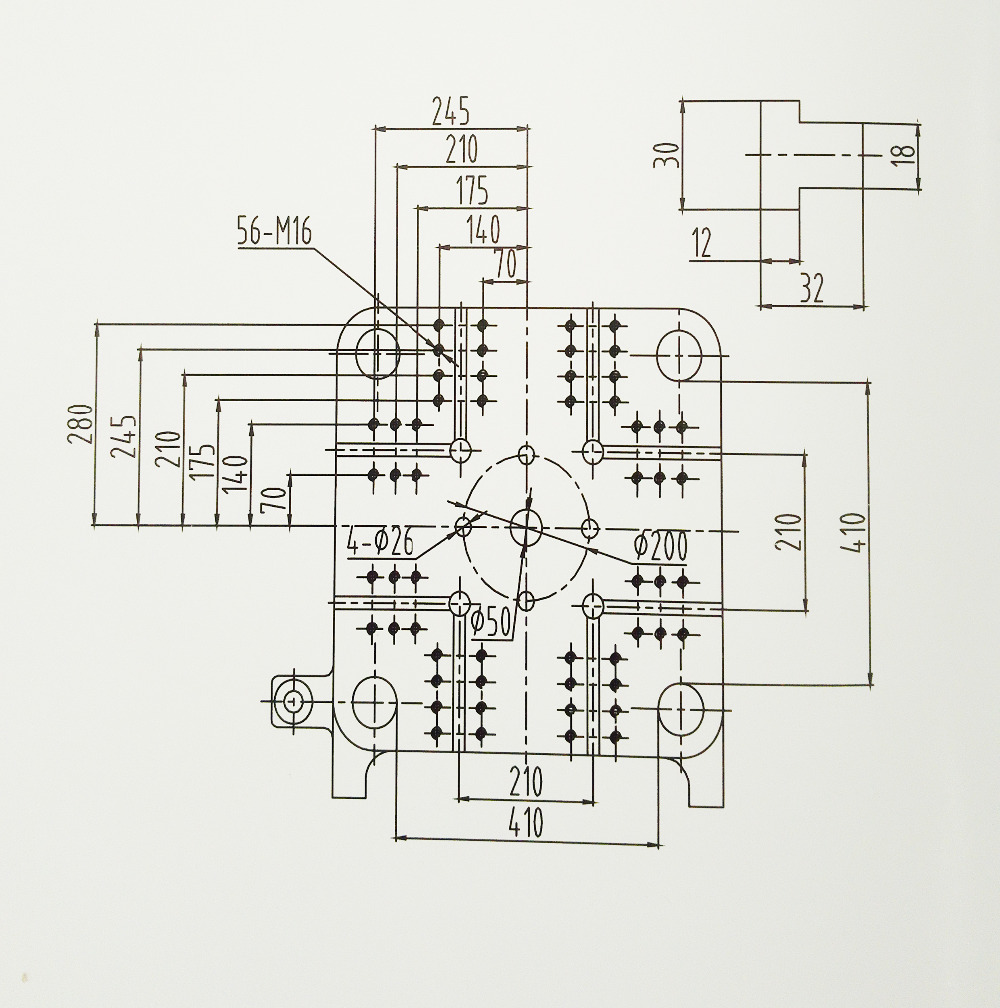

Space between tie bar: 410mm*410mm

Color: Green

Machine weight: 4T

Screw Diameter: 38-45mm

Machine dimension(L*W*H): 4.6*1.2*1.8

Warranty: 1 Year

Material: Stainless Steel

Machine: Thermoplastic Injection Moulding Machine

| Description | Unit | LOG-130A8 | ||

| international recognized models | 416/130 | |||

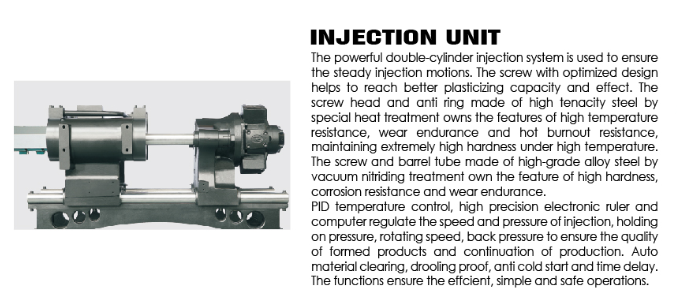

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

| Shot volume | g | 196 | 239 | 274 |

| Oz | 6.9 | 8.4 | 9.6 | |

| Screw diameter | mm | 38 | 42 | 45 |

| Injection diameter | mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 190 | ||

| Screw rotate speed | r/min | 180 | ||

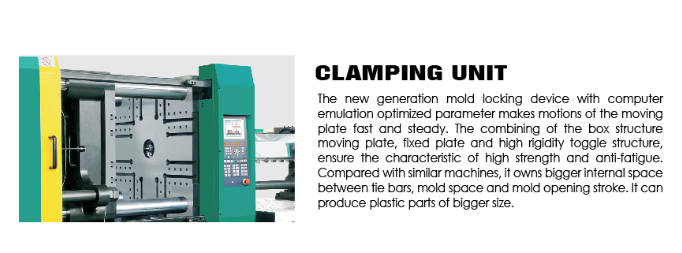

| CLAMPING UNIT | ||||

| Clamping force | kN | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Maldthickness | mm | 150-430 | ||

| Platen Mix stroke | mm | 810 | ||

| Ejection stroke | mm | 120 | ||

| Ejcetion force | kN | 42 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 12 | ||

| Heating power | kw | 7.7 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 1.3 | ||

| Tank volume | L | 200 | ||

| Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

| Weight of machine | kg | 4000 | ||

Packaging Details: 20 GPcabinet Delivery

Delivery Detail: two weeks after get payment

| INJECTION | LOG130 | |||

| A | B | C | ||

| Shot volume | cm³ | 215 | 263 | 302 |

| Shot weight (ps) | G | 196 | 239 | 274 |

| oz | 7 | 8 | 10 | |

| Max injection rate | cm³/s | 97 | 118 | 163 |

| Screw diameter | mm | 38 | 42 | 45 |

| Plasticizing rate | Kg/h | 46 | 60 | 75 |

| Injection pressure | Mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| screw speed | r/min | 0~180 | ||

| CLAMPING | ||||

| Clamping force | Kn | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Mold thickness (Min--Max) | mm | 150~430 | ||

| Hydraulic ejection stroke | mm | 120 | ||

| Hydraulic ejection force | Kn | 42 | ||

| Power Unit | ||||

| Hydraulic system pressure | Mpa | 17.5 | ||

| Pump motor | Kw | 11 | ||

| Heating capacity | Kw | 7.7 | ||

| Number of temp control zones | 4+ (nozzle) | |||

| GENERAL | ||||

| Dry-cycle time | sec | 1.3 | ||

| oil tank capacity | L | 200 | ||

| Machine dimensions | m*m*m | 4.6*1.2*1.8 | ||

| Machine weight | kg | 3550 | ||

Platen Dimensions:

product 1

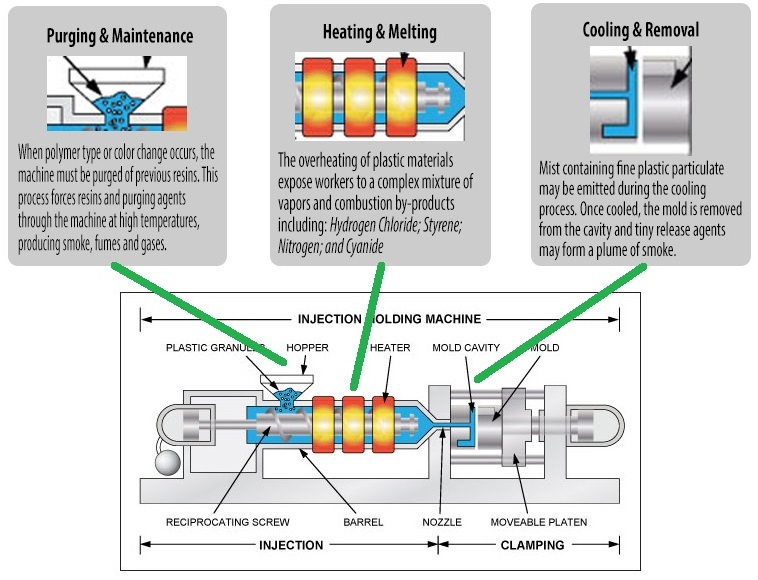

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q:The use of injection molding machines

- Servo energy-saving injection molding machine series, equipped with servo transmission power control system with high performance, in the process of injection molding machine in different flow pressure, make the output frequencies, and accurate closed-loop control of pressure and flow, high speed response and the best matching and automatic adjustment of the servo motor of the injection molding machine energy demand.1 、 using excellent servo controller, servo motor and other energy-saving devices.2 、 sensitive servo control system, quick start-up, reaction time is only 0.04S.3, servo motor and hydraulic system constitute closed-loop control, compared to the traditional model, the repeatability is greatly improved4, reduce the impact of the lock mold, and extend the service life of mechanical components and dies5, reduce the use of electricity, in the ideal working condition of the model than the traditional injection molding machine energy saving efficiency can reach 20%80%6, the system heat is much lower than the traditional injection molding machine, saving about 30% of the cooling water consumption, extending the oil seal and hydraulic parts life7, the whole line is running low noise, significantly lower than the traditional injection molding machine

- Q:What kind of after-sales service, which friends know to introduce?

- The best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q:Haitian injection molding machine alarm, hydraulic insurance exception, what are the reasons?

- The problem is on hydraulic oil, such as insufficient hydraulic oil, hydraulic oil containing impurities. Check, either add hydraulic oil, or replace the hydraulic oil.

- Q:Does the injection machine have to use cooling water?

- Three. The temperature difference of the ice water at the inlet and outlet of the mold is usually set according to the requirements of the product. In many cases, the temperature difference is 3-5 degrees centigrade, which is ideal, but sometimes the temperature difference is 1-2 degrees centigrade. The smaller the temperature, the greater the amount of ice water required to bring out the same amount of heat, and the less needed traffic. For example: when the temperature difference is 5 degrees centigrade, the flow rate needs 60L, but when the temperature difference is 2 DEG C, the flow rate needs 150L.Four, ice water flow: a pair of mold required water flow directly with the mold to take away the heat and ice water and the temperature difference between the mold. For example: 6480 kcal / h heat from the die away, if the temperature is 3 DEG C, water flow Q=6480 / 3 / 60=36 (L / min).Five, water temperature of cooling fluid (water): mould temperature is generally subject to the processing of materials and products shape changed greatly, such as polystyrene thin beaker, die ice water temperature at 0 DEG C; and in most cases, the mold required ice water in the temperature of 5 DEG C, a full function of cold water can provide the above 5 degrees of ice water, cold water can meet the low temperature type intelligent temperature below 5 DEG and 0 DEG C requirements. The connection between the water cooler and the mold is usually connected with an enhanced hose, because the hose itself has the function of heat insulation, but the length is more than 5m, and it should also consider moderate thermal insulation.

- Q:Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 2. vertical machine has the advantages of small footprint, relatively low prices, shortcomings, such as high gravity, inconvenient to take parts, etc., suitable for small molds.

- Q:What's the meaning of the connection between the injection machine and the manipulator?

- 1 injection molding machine mold, waiting for2 the robot receives the signal and completes the action3 after completion, send a signal to the injection molding machine4 the injection machine continues to complete the action;The above is the process in which the manipulator sends the parts into the injection machine, and if the lower parts are the opposite signal.

- Q:What kind of lubricant does the injection machine use?

- The main use of antiwear hydraulic oil, as well as 00-000, extreme pressure grease

- Q:What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of the cylinder, increase the speed of die closing, shorten the cooling and holding time, reduce the time of back compression and short sol, and speed up the movement with mould opening

- Q:How many solenoid valves are there on the injection molding machine?

- Solenoid valve is used to control the automation of the fluid basic components, belonging to the actuator; not limited to hydraulic, pneumatic. Solenoid valve used to control the direction of hydraulic flow, the factory's mechanical devices are generally controlled by hydraulic steel, so it will use the solenoid valve.

- Q:How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords