Aluminium Coil for Roofing & ACP Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

If your roof exhibits any of the above symptoms—or if your roof is simply old—The Aluminum Company will gladly examine your roof as a courtesy to help you determine whether it can be repaired or needs to be replaced. This service call is without any cost or obligation to you.

3. Feature of Aluminum

If your roof exhibits any of the above symptoms—or if your roof is simply old—The Aluminum Company will gladly examine your roof as a courtesy to help you determine whether it can be repaired or needs to be replaced. This service call is without any cost or obligation to you.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

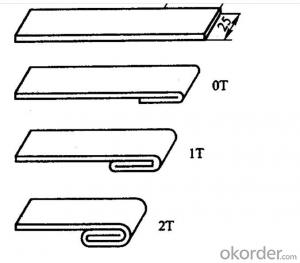

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:Can aluminum coils be used in electrical or electronic applications?

- Aluminum coils find utility in electrical and electronic applications. This material, known for its high conductivity, offers various advantages over alternatives like copper in coil applications. Their lightweight nature renders aluminum coils appropriate for weight-sensitive applications. Furthermore, they possess excellent thermal conductivity, ensuring efficient dissipation of heat. Moreover, aluminum coils exhibit resistance to corrosion, making them durable and suitable for outdoor or high-humidity settings. Nonetheless, it is crucial to acknowledge that aluminum's electrical conductivity is lower than that of copper. Hence, the coil's design and dimensions must be meticulously considered to ensure optimal performance.

- Q:What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils can vary depending on their specific alloy composition and application. However, in general, aluminum coils can withstand temperatures up to around 600 degrees Fahrenheit (315 degrees Celsius) before their structural integrity and performance may be compromised.

- Q:Can aluminum coils be used in the production of consumer goods?

- Yes, aluminum coils can be used in the production of consumer goods. Aluminum is a versatile material that is lightweight, durable, and corrosion-resistant, making it suitable for a wide range of applications such as cans, packaging, appliances, and automotive parts. The flexibility and formability of aluminum coils allow manufacturers to create various consumer products efficiently and cost-effectively.

- Q:Hey everybody I'm trying to improve the performance of my vintage metal Coleman cooler I just got. To test it I filled it up with water bottles and 5lbs of cubed ice from Stop and Shop and left it in the closet with the dorm's AC set to 65. When I got back 28 hours later the ice was completely melted. The water still kept the drinks cool for several days after that, but I'm frustrated that the ice melted in a single day.

- It's perfect if you are just starting out or if you're a seasoned carpenter. you will like it for sure ! It has almost 20.000 woodworking plans and you have a CAD/DWG software to view and edit the plans. You have step-by-step instructions with photos and high quality blueprints and schematics. If you are a beginner this is the easiest way to start your woodworking projects, and if you already have experience you can anyway find a lot of interesting ideas!

- Q:im doing this essay in my chemistry class that suppose to be a ficional story about the day my element, aluminum, slowly began disappearing.i know some things that will happen like no soda cans of anything of that, no foil no forks or spoons anything metally. i need more effects that will happen but my major problem is how to start this. i have no clue like how to begin.can anyone help pleased.!

- can someone give me the information about aluminum for: It's cost today and back then when first found It's availibility: today and back then, and explaining why The environmental concerns: today and back then Health concerns: today and back then Explaining why Effectiveness of the material and it's hazrds PLease and thank you

- Q:Are aluminum coils suitable for decorative purposes?

- Yes, aluminum coils are suitable for decorative purposes. They are lightweight, durable, and can be easily shaped and colored to create various decorative elements such as trim, edging, and accents. Additionally, aluminum coils are resistant to corrosion, making them ideal for both indoor and outdoor decorative applications.

- Q:what is aluminium toxic amount on a human's general physiological system? and what is the usual amount aluminium injested?thankyou

- It is estimated that the normal person takes in between 3 and 10 milligrams of aluminum per day. Aluminum is the most abundant metallic element produced by the earth. It can be absorbed into the body through the digestive tract, the lungs and the skin, and is also absorbed by and accumulates in the bodies tissues. Aluminum is found naturally in our air, water and soil. It is also used in the process of making cooking pots and pans, utensils and foil. Other items such as over the counter pain killers, anti-inflammatory products, and douche preparations can also contain aluminum. Aluminum is also an additive in most baking powders, is used in food processing, and is present in antiperspirants, toothpaste, dental amalgams, bleached flour, grated cheese, table salt, and beer, (especially when the beer is in aluminum cans). The biggest source of aluminum, however, comes from our municipal water supplies. Aluminum is excreted by the kidneys, therefore toxic amounts can impair kidney function. Aluminum can also accumulate in the brain causing seizures and reduced mental alertness. The brain is normally protected by a blood-brain barrier, which filters the blood before it reaches it. Elemental aluminum does not pass easily through this barrier, but certain compounds contained within aluminum, such as aluminum fluoride do. Interestingly, many municipal water supplies are treated with both aluminum sulfate and aluminum fluoride. These two chemicals can also combine easily in the blood. Aluminum fluoride is also poorly excreted in the urine.

- Q:What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 g/cm³, and the specific gravity value is approximately 2.7.

- Q:What type of equipment is used to process aluminum coils?

- The equipment employed for aluminum coil processing varies depending on the specific manufacturing process and requirements. Nevertheless, there are several common types of equipment used in this process: 1. Uncoilers/Decoilers: These machines are utilized to unroll and straighten the aluminum coils, facilitating further processing. 2. Levelers: Leveling machines are employed to flatten the surface of the aluminum coil, ensuring it is even and flat before proceeding with additional processing. 3. Slitters: Slitting machines are used to cut the aluminum coil into narrower strips of desired widths. This equipment finds frequent use in industries such as automotive, construction, and packaging. 4. Shears: Shearing machines are employed to cut the aluminum coil into specific lengths or shapes required for the manufacturing process. 5. Roll Forming Equipment: Roll forming machines shape the aluminum coil into specific profiles or designs. Commonly employed in the construction industry, they are used to manufacture roofing panels, gutters, and siding. 6. Heat Treatment Furnaces: Heat treatment furnaces subject the aluminum coil to specific temperature conditions to enhance its strength, hardness, or other desired properties. 7. Surface Treatment Equipment: Various equipment, including cleaning machines, chemical baths, and coating lines, are used for surface treatment processes such as cleaning, anodizing, or painting the aluminum coil. These processes improve the coil's appearance, corrosion resistance, or other functional properties. 8. Packaging Equipment: Packaging machines are employed to bundle, wrap, or pack the processed aluminum coils for storage, transportation, or further distribution. It is crucial to note that the specific equipment used may vary depending on factors such as size, thickness, alloy, and intended use of the aluminum coils. Manufacturers often utilize customized equipment to meet their specific requirements and ensure efficient processing.

- Q:What's the color coated aluminum roll?

- Colour coated aluminium coil product information:Product category: polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF)Mylar coated aluminum coilIs a kind of anti UV ultraviolet coating, polyester resin is used in the main chain of ester containing polymer polymer as monomer, add alkyd resin, UV absorber according to gloss, can be divided into sub light and high light series. The utility model is especially suitable for indoor decoration and advertisement boards.Fluorocarbon coating aluminum coilFluorocarbon resin is a kind of fluorocarbon resin, which is composed of pigments, alcohols, esters, solvents and assistants. High temperature barbecue film,The molecular structure of the coating is close and has super weatherability. Fluorocarbon coatings can be divided into two kinds: traditional fluorocarbon and nano fluorocarbon coating according to the surface film forming structure.The utility model is especially suitable for the decoration and display of indoor, outdoor decoration, commercial chain, exhibition advertisement, etc. in public places

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Coil for Roofing & ACP Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords