Mill Finish Aluminium Coil for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Aluminium Coil for Color Coating

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Mill Finish Aluminium Coil for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Coil for Color Coating

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

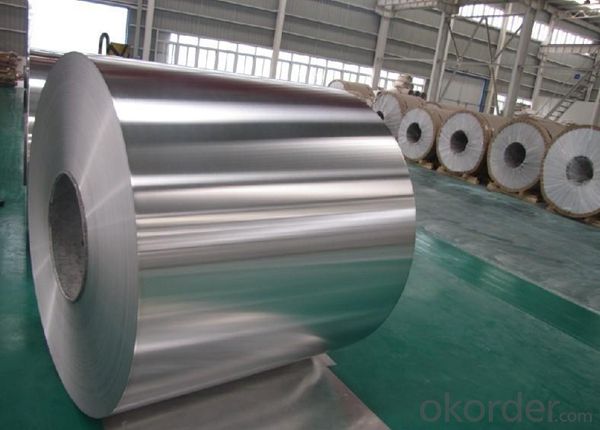

5. Image of Mill Finish Aluminium Coil for Color Coating

6. Package and shipping of Mill Finish Aluminium Coil for Color Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Are aluminum coils suitable for corrosion-resistant applications?

- Aluminum coils are highly suitable for applications requiring resistance to corrosion. This is because aluminum naturally develops a protective oxide layer on its surface, offering excellent defense against corrosion caused by moisture, chemicals, and environmental elements. Furthermore, aluminum's corrosion resistance can be further augmented through the application of diverse coatings and treatments. Consequently, aluminum coils find widespread use in critical areas where corrosion resistance is paramount, such as the construction industry, automotive sector, and marine applications.

- Q:Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum is a highly efficient and effective material for heat transfer due to its high thermal conductivity. It can quickly transfer heat from one medium to another, making it ideal for heat exchangers where efficient heat transfer is required. Additionally, aluminum coils are lightweight, corrosion-resistant, and have excellent durability, making them a popular choice for various applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can withstand harsh environments and prevent the formation of rust or corrosion, prolonging the lifespan of the heat exchanger. Moreover, aluminum coils are easily moldable and can be formed into various shapes, allowing for flexibility in design and construction of heat exchangers. This versatility makes them suitable for a wide range of applications, including HVAC systems, refrigeration units, and automotive cooling systems. In summary, aluminum coils are well-suited for heat exchangers due to their high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility. These properties make aluminum coils an excellent choice for efficient heat transfer in various industries.

- Q:Its currently 3 AM so i can't check, but my question is:does aluminum rust slower/faster than other metals? I've basically had this bike for about 6 years, but only rid it once. Its been sitting in my backyard under a roof (safe from rain) for 6+ years. Is it safe to ride it? Also, bonus question: Does having a bike on campus make life 10x easier?

- Aluminium could fracture without warning especially as the bike has been neglected for so long -all rubbers would probably need replacing cables is it some sort of collectors item? If not and you are just using it on campus ditch it and get a new bike (from a dealer) nothing fancy maybe add a rack for your books

- Q:Are aluminum coils suitable for high-gloss applications?

- High-gloss applications can benefit greatly from the use of aluminum coils. This metal possesses outstanding reflective qualities and, when treated and finished correctly, can achieve a remarkable level of shine and gloss. Its smooth surface and reflective nature work together to enhance the appearance of high-gloss finishes, making it an excellent choice for those seeking a polished and shiny look. Aside from its aesthetic advantages, aluminum also offers several practical benefits for high-gloss applications. It is lightweight, durable, and resistant to corrosion, making it a reliable and low-maintenance option. Moreover, aluminum coils are highly malleable, allowing them to be easily molded into different shapes and sizes, a crucial aspect when aiming for the desired high-gloss design. Moreover, aluminum coils can be coated with various finishes, such as anodized coatings or high-quality paint systems, to further enhance their durability and glossiness. These coatings provide an extra layer of protection against scratches, fading, and other forms of wear and tear, ensuring the long-lasting maintenance of the high-gloss appearance. To summarize, aluminum coils are a perfect choice for high-gloss applications due to their reflective properties, versatility, and durability. With the right treatment and finishing, aluminum can provide a stunning and enduring glossy finish, making it highly sought after in diverse industries, including automotive, architecture, and interior design.

- Q:What are the common surface treatments for aluminum coils in the automotive industry?

- In the automotive industry, aluminum coils undergo various surface treatments to enhance their performance and appearance. Some common surface treatments for aluminum coils in the automotive industry include: 1. Anodizing: Anodizing is a popular surface treatment for aluminum coils as it creates a protective oxide layer on the surface. This process involves immersing the coils in an electrolytic solution and passing an electric current through it. Anodizing provides corrosion resistance, improves durability, and allows for the application of dyes or paints. 2. Painting: Aluminum coils can be painted to provide an aesthetically pleasing appearance and protection against environmental factors. The coils are coated with a layer of paint, which can be solvent-based or powder-coated. Painting not only enhances the visual appeal but also adds a layer of protection against scratches and UV radiation. 3. Cladding: Cladding involves bonding a layer of aluminum alloy with different properties onto the surface of the coil. This treatment is commonly used to improve the strength, thermal conductivity, or corrosion resistance of the aluminum coil. Cladding can be done through various methods, such as hot rolling, cold rolling, or explosive bonding. 4. Clear Coating: Clear coating is often applied to aluminum coils to provide a transparent protective layer. This coating helps prevent corrosion, oxidation, and discoloration, while also preserving the natural metallic appearance of the aluminum coil. 5. Polishing and Buffing: Polishing and buffing are surface treatments that aim to enhance the surface smoothness and shine of aluminum coils. These treatments involve mechanically grinding or polishing the surface to remove imperfections, scratches, and oxidation. Polishing and buffing are commonly used for decorative purposes in high-end automotive applications. These are just a few of the common surface treatments for aluminum coils in the automotive industry. The choice of treatment depends on factors such as the desired appearance, performance requirements, and environmental conditions the coils will be exposed to.

- Q:Can aluminum coils be used for roofing?

- Certainly, roofing can be done using aluminum coils. Aluminum is widely regarded as a top preference for roofing materials because of its sturdy composition, lightweight properties, and exceptional resistance to corrosion. In a wide range of roofing applications, including residential, commercial, and industrial structures, aluminum roofing coils are frequently employed. They offer exceptional safeguarding against severe weather conditions like intense rainfall, snowfall, and powerful winds. Furthermore, aluminum coils possess energy-efficient attributes as they possess the ability to reflect solar heat, thereby aiding in preserving a cool indoor environment and reducing energy expenditures. All in all, aluminum coils present a dependable and enduring roofing solution.

- Q:Are there any limitations on the length of aluminum coils?

- Yes, there are limitations on the length of aluminum coils. The length of aluminum coils is typically limited by practical considerations, such as transportation and handling capabilities. Additionally, longer coils may become more susceptible to bending, warping, or other forms of damage. Consequently, manufacturers often have specific maximum length specifications for aluminum coils.

- Q:having trouble looking for tis information, don't know where to look.Is aluminum accessible to everyone?? Does it cost a lot, is it in minimal areas if so is it hard to transport to all around the world??

- I can't understand you question.do you mean how aluminum works?

- Q:What is the typical heat transfer coefficient for aluminum coils?

- The heat transfer coefficient for aluminum coils can vary depending on several factors, including the application, coil geometry, and surrounding conditions. Generally, aluminum has high thermal conductivity, which enables efficient heat conduction. In forced convection applications, where heat is transferred using a fluid like air or water, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This is because the movement of air is slower and the heat transfer effectiveness is reduced compared to forced convection. It's important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q:Can aluminum coils be used for architectural applications?

- Aluminum coils are indeed applicable for architectural purposes. With its versatility and lightweight nature, aluminum is an ideal material that boasts exceptional resistance against corrosion, making it suitable for numerous architectural applications. Exterior cladding, roofing, facades, and even interior uses like ceilings and wall panels can all benefit from the utilization of aluminum coils. These coils are easily malleable, cuttable, and moldable, allowing for flexibility in design and innovative architectural solutions. Moreover, aluminum coils can be coated with diverse finishes, such as paint or anodized coatings, to enhance both aesthetics and durability. All in all, due to their adaptability, durability, and aesthetic charm, aluminum coils are highly favored within the architectural industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminium Coil for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords