Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

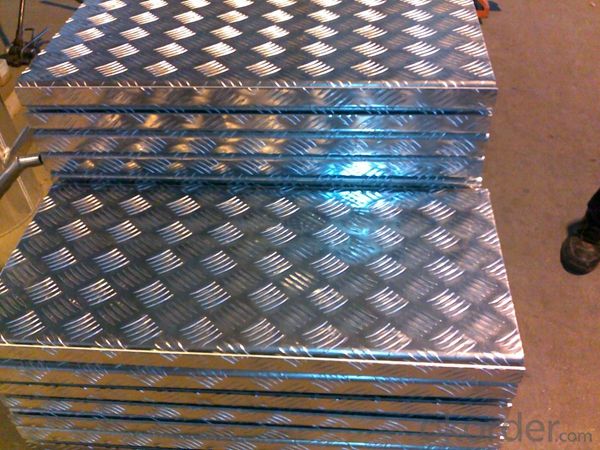

5. Image of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight nature, durability, and corrosion resistance. Aluminum sheets can be easily formed into various shapes and sizes, making them suitable for creating the structural frame of curtain walls. Additionally, aluminum can be coated or anodized to enhance its aesthetic appeal and provide additional protection against weather elements. This makes aluminum sheets a versatile and practical material for constructing curtain walls in commercial and residential buildings.

- Q:Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

- Q:4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.

- Q:What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q:Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q:Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

- Q:Can aluminum sheets be polished?

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Q:How do aluminum sheets perform in terms of electrical conductivity?

- Known for their excellent electrical conductivity, aluminum sheets are highly conductive and rank second only to copper among common metals. This exceptional conductivity makes aluminum sheets ideal for a range of electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum enables efficient electricity transfer, leading to minimal energy loss during transmission. Furthermore, the lightweight nature of aluminum sheets makes them a preferred material for electrical systems that prioritize weight reduction. In conclusion, aluminum sheets provide exceptional electrical conductivity and are a reliable and efficient choice for electrical applications.

- Q:What are the different types of patterns available for aluminum sheets?

- There are several different types of patterns available for aluminum sheets, including diamond, tread, stucco, and perforated. Each pattern offers unique aesthetic and functional properties, catering to various applications and design preferences.

- Q:Can aluminum sheets be textured or patterned?

- Indeed, it is possible to texture or pattern aluminum sheets. Numerous techniques exist for achieving desired textures or patterns on aluminum sheets, including embossing, engraving, or etching. These methods entail modifying the surface of the aluminum sheet to achieve the desired texture or pattern. Furthermore, aluminum sheets can also be coated or painted with various finishes or colors to attain a specific textured or patterned appearance. In summary, by employing appropriate techniques and processes, aluminum sheets can be extensively transformed and personalized to possess a diverse array of textures and patterns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords