Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Corrugated Aluminum Tile in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

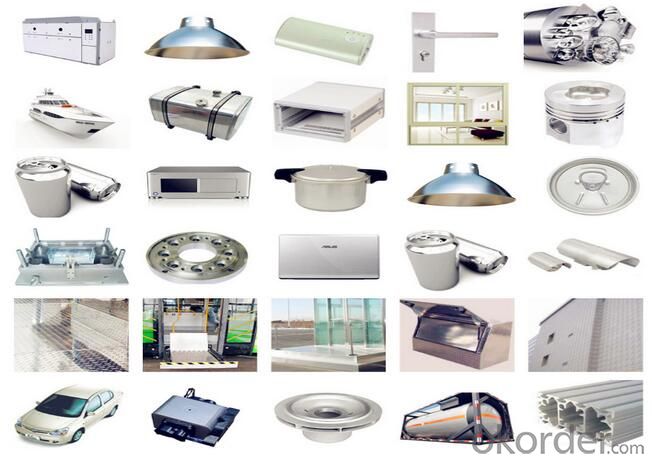

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q:Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q:Can the aluminum sheets be used for manufacturing chemical piping systems?

- Yes, aluminum sheets can be used for manufacturing chemical piping systems. Aluminum is known for its excellent corrosion resistance, which makes it suitable for handling various chemicals. It is also lightweight, making installation and maintenance easier. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer in chemical processes. However, it is important to consider the specific requirements of the chemicals being transported and consult with experts to ensure that the aluminum sheets chosen have the necessary properties and are compatible with the chemicals to be used in the piping system.

- Q:Are aluminum sheets non-magnetic?

- Indeed, aluminum sheets lack magnetic properties as they are not ferromagnetic. Instead, they fall under the classification of paramagnetic materials with a feeble reaction to magnetic fields. Consequently, aluminum sheets fail to exert any magnetic attraction or retention.

- Q:Can aluminum sheet be used for automotive body-in-white applications?

- Yes, aluminum sheet can be used for automotive body-in-white applications. Aluminum is lightweight, yet strong and durable, making it an ideal material for automotive applications. It offers a high strength-to-weight ratio, which helps improve fuel efficiency and overall vehicle performance. Additionally, aluminum's corrosion resistance properties make it suitable for withstanding harsh environmental conditions. Its formability allows for complex and intricate designs, enabling manufacturers to create lightweight yet rigid automotive structures. The use of aluminum in automotive body-in-white applications has become increasingly popular in recent years, as it helps reduce vehicle weight and emissions while maximizing safety and performance.

- Q:Are aluminum sheets suitable for chemical storage tanks?

- Yes, aluminum sheets can be suitable for chemical storage tanks depending on the specific requirements of the chemical being stored. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing many chemicals. It forms a protective oxide layer that prevents further corrosion, even when exposed to harsh environments. However, it is important to consider the compatibility of the chemical with aluminum. Some chemicals, such as strong acids or bases, may react with aluminum and cause corrosion or other undesirable reactions. In such cases, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) may be more suitable. Additionally, the thickness and grade of the aluminum sheets should be chosen carefully based on the specific chemical being stored and the tank's intended use. Thicker sheets may be necessary for storing highly corrosive or hazardous chemicals, while thinner sheets may be sufficient for less aggressive substances. Overall, aluminum sheets can be a suitable choice for chemical storage tanks, but it is crucial to carefully evaluate the chemical compatibility and select the appropriate thickness and grade of aluminum to ensure safe and reliable storage.

- Q:Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is a versatile material that offers several advantages for this purpose. It is lightweight, corrosion-resistant, and has high strength-to-weight ratio. These properties make it suitable for storing various chemicals safely. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for customization of storage tanks to meet specific requirements. However, it is important to consider the type and concentration of chemicals being stored, as some chemicals may react with aluminum. In such cases, appropriate coatings or linings may be necessary to prevent any chemical reactions.

- Q:What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q:Can aluminum sheets be used for signage?

- Signage can indeed utilize aluminum sheets. Aluminum, a versatile and durable material, is frequently employed in the sign-making industry. Its lightweight yet sturdy properties make it well-suited for both outdoor and indoor signage. Additionally, aluminum sheets are resistant to corrosion, rust, and fading, guaranteeing signage longevity. They can also be easily cut and shaped into various sizes and designs, providing creative and customized signage solutions. Furthermore, the material offers a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly adaptable for different signage applications. In conclusion, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a favored choice for signage.

- Q:Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q:What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords