Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Whole Steel Formwork Description

CMAX Whole Steel Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort. 55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Construction Steel Formwork

- Simple structure, high loading capacity.

- Light weight, easy assemble.

- Excellent surface quality of formed concrete.

- We can special design according to any requirements.

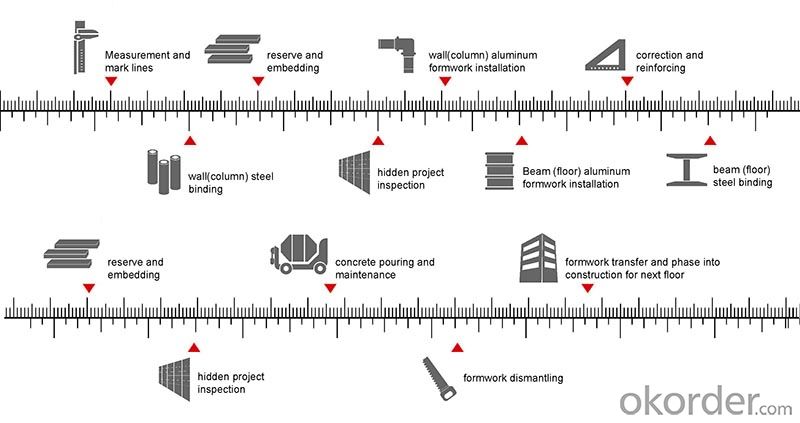

3. Construction Process

4. FAQ of Steel Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:How long does it take to set up steel formwork?

- The time it takes to set up steel formwork depends on various factors such as the complexity of the structure, the experience and skill level of the workers, the size of the project, and the availability of equipment. Generally, setting up steel formwork can take anywhere from a few hours to several days. For smaller projects with simple structures, a team of experienced workers can typically set up the formwork within a day or two. This includes measuring and marking the layout, assembling the steel panels, beams, and props, and securing them in place. The process may also involve attaching braces and ties to ensure stability and alignment. On the other hand, larger and more complex projects may require more time for formwork setup. This could involve intricate designs, multiple levels or floors, and a higher number of formwork components. In such cases, the setup process may take several days or even weeks, depending on the size of the team and the availability of resources. It's important to note that while steel formwork may take longer to set up compared to other types of formwork such as timber or plastic, it offers benefits such as durability, reusability, and better stability. These advantages outweigh the additional time required for setup, especially for large-scale construction projects that require strong and reliable formwork systems.

- Q:Production of steel plate for bridge steel plate SPHC and Q235 which material is good? What is the difference?

- SPHC this brand is actually the first brand in Germany, Japan also used,

- Q:How does steel formwork affect the overall construction site noise pollution?

- Steel formwork can have a significant impact on reducing overall construction site noise pollution. Compared to traditional wooden formwork, steel formwork offers better acoustic insulation properties. The rigid and dense nature of steel materials helps to absorb and dampen sound waves, minimizing the propagation of noise. This reduced noise propagation can be especially beneficial in densely populated areas or construction sites located near residential or commercial areas. Furthermore, steel formwork is often prefabricated, meaning it is manufactured off-site and then assembled on-site. This process helps to reduce construction noise as it requires fewer on-site activities and reduces the need for cutting, drilling, and hammering, which are major sources of noise pollution. Additionally, the use of steel formwork can lead to faster construction times, resulting in shorter exposure to noise for neighboring communities. Moreover, steel formwork is more durable and long-lasting than wooden formwork, which means it can be reused multiple times. This reusability reduces the need for frequent formwork installation and dismantling, further decreasing noise pollution generated during the construction process. Overall, the use of steel formwork in construction can greatly contribute to minimizing noise pollution at the construction site. Its superior acoustic insulation properties, reduced on-site activities, and longer lifespan all work together to create a quieter and more environmentally friendly construction environment.

- Q:Can steel formwork be used for precast concrete facades with intricate patterns?

- Yes, steel formwork can be used for precast concrete facades with intricate patterns. Steel formwork is known for its strength and durability, making it suitable for creating complex and detailed designs. The flexibility of steel allows for the creation of intricate patterns, textures, and shapes on the surface of the concrete. Additionally, steel formwork can be easily adjusted and modified to accommodate any desired pattern or design. This makes it a popular choice for precast concrete facades that require intricate patterns or artistic elements. Overall, steel formwork provides the necessary support and versatility to achieve complex designs in precast concrete facades.

- Q:How does steel formwork contribute to the overall sustainability credentials of the project?

- Steel formwork contributes to the overall sustainability credentials of a project in several ways. Firstly, steel is a highly durable material, which means that it can be reused multiple times, reducing the need for new materials and minimizing waste. Additionally, steel formwork allows for greater flexibility in design, enabling efficient use of materials and reducing construction time and costs. Moreover, steel is a recyclable material, so at the end of its life cycle, it can be recycled and used in other projects, further reducing environmental impact. Overall, steel formwork helps to promote sustainability by promoting resource efficiency, reducing waste, and minimizing the carbon footprint of construction projects.

- Q:Can steel formwork be used in seismic areas?

- Steel formwork is indeed applicable in seismic regions due to its strength, durability, and stability. Its ability to endure the forces and vibrations produced during an earthquake guarantees the safety and stability of the structures under construction. Moreover, the quick construction facilitated by steel formwork is advantageous in seismic areas where timeliness is crucial for ensuring the security of the built environment. Nevertheless, it is vital to ensure that the steel formwork is correctly designed and installed to meet the area's specific seismic design requirements and codes.

- Q:What are the safety precautions when using steel formwork?

- When using steel formwork, it is important to follow a few safety precautions. Firstly, ensure that the formwork is properly inspected and maintained before use to identify any potential hazards or structural weaknesses. Secondly, use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from injuries. Additionally, make sure to handle the steel formwork properly, using proper lifting techniques and avoiding overloading. Lastly, ensure that the work area is properly secured and stable to prevent accidents or collapses.

- Q:How does steel formwork handle different concrete curing time requirements?

- Steel formwork proves to be a versatile and durable choice for construction projects, including those involving concrete structures. In terms of managing diverse concrete curing time needs, steel formwork presents numerous advantages. To begin with, steel formwork establishes a sturdy and secure framework for pouring concrete. This guarantees that the concrete remains in place and retains its desired shape throughout the curing process. Irrespective of the required curing time, steel formwork effectively withstands the weight and pressure exerted by the concrete, preventing any distortion or collapse. Furthermore, steel formwork boasts high adjustability and customizability. It can be easily modified to accommodate varying curing time requirements. For instance, if a specific section of concrete necessitates a lengthier curing time, supplementary support can be added to the steel formwork, providing extra strength and stability. Conversely, if a section requires a shorter curing time, the steel formwork can be adjusted accordingly to expedite the curing process. In addition, steel formwork possesses excellent heat conductivity properties. This facilitates efficient dissipation of heat during concrete curing. Different concrete mixes may generate heat at varying rates during hydration, and steel formwork assists in maintaining consistent curing temperatures. This proves particularly advantageous when dealing with concrete structures that demand specific curing temperatures. Moreover, steel formwork is reusable and capable of enduring multiple casting cycles. Consequently, it can be utilized for diverse projects with varying concrete curing time requirements, making it a cost-effective option. The durability and strength of steel formwork ensure its longevity, enabling contractors to adapt to different curing time needs without the need for constant replacement. In conclusion, steel formwork proves to be highly suitable for managing different concrete curing time requirements. Its stability, adjustability, heat conductivity, and reusability render it an ideal selection for construction projects of varying scales and complexities. Whether the concrete necessitates a longer or shorter curing time, steel formwork provides the essential support and flexibility to ensure successful curing and the creation of robust and enduring concrete structures.

- Q:How does steel formwork affect the overall structural integrity of a building?

- Steel formwork plays a crucial role in ensuring the overall structural integrity of a building. It is a temporary mold or framework that is used during the construction process to shape and support concrete until it hardens and gains sufficient strength to bear its own weight and other applied loads. One of the key advantages of steel formwork is its superior strength and durability compared to other types of formwork such as wood or plastic. Steel is known for its high tensile strength and resistance to deformation, which allows it to withstand the pressure exerted by wet concrete without any significant distortion. This strength ensures that the formwork maintains its shape and stability during the pouring and curing of concrete, preventing any potential collapse or failure that could compromise the structural integrity of the building. Moreover, the use of steel formwork provides precise and accurate results in terms of dimension and shape, which is essential for achieving the desired structural integrity. Steel formwork can be fabricated to exact specifications, allowing for tight tolerances and accurate positioning of reinforcement, resulting in a more uniform and robust structure. This precision ensures that the building can withstand various external loads, such as wind, seismic forces, and live loads, without experiencing excessive deflection or deformation. Additionally, steel formwork offers excellent reusability, making it a cost-effective and sustainable option in construction projects. Unlike other types of formwork that may require frequent replacement, steel formwork can be used multiple times, reducing material waste and overall project costs. This reusability also contributes to the structural integrity of the building, as the formwork is less prone to deterioration or degradation over time, ensuring consistent quality and performance. In summary, steel formwork significantly enhances the overall structural integrity of a building by providing superior strength, precision, and durability. Its ability to withstand the pressure of wet concrete, maintain accurate dimensions, and resist external loads ensures the structural stability and safety of the building. Moreover, the reusability of steel formwork offers cost-effective and sustainable advantages, further contributing to the long-term structural integrity of the constructed building.

- Q:Is steel formwork suitable for projects with high formwork reusability?

- Yes, steel formwork is highly suitable for projects with high formwork reusability. Steel formwork is known for its durability, strength, and longevity, making it ideal for repetitive use in construction projects. It can withstand multiple pour and stripping cycles without significant wear and tear, ensuring cost-effectiveness and efficiency in projects that require frequent formwork reuse. Additionally, steel formwork offers excellent dimensional stability, allowing for precise and accurate concrete shaping and finishing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products