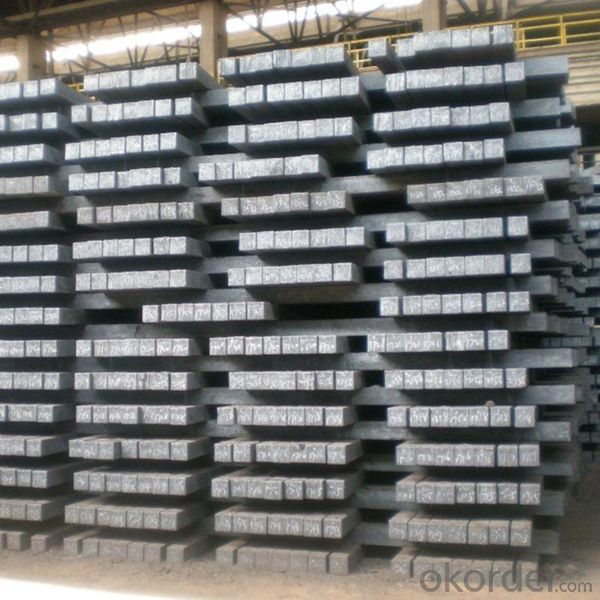

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

TK 440 superior hot rolled Carbon Steel Billets Square Billets

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195/215/235/345/45#/3SP/5SP,ect

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

- Q:What are the main properties of steel billets?

- Steel billets serve as the initial material for various steel products and possess several important properties that make them suitable for further shaping and processing. To begin with, steel billets demonstrate a high level of strength and durability. This is primarily attributed to the composition of steel, which consists mainly of iron with small amounts of carbon and other elements. This composition provides steel billets with exceptional mechanical properties, including high tensile strength and resistance to deformation. Moreover, steel billets exhibit favorable heat transfer properties. Steel is renowned for its efficient heat conductivity, making it an ideal material for applications requiring thermal conductivity, such as the production of automotive parts or construction materials. Furthermore, steel billets possess excellent machinability. Machinability refers to the ease with which a material can be shaped or formed using various machining processes. Steel billets can be easily cut, drilled, and shaped into desired forms, enabling efficient processing and fabrication. Additionally, steel billets display superb weldability. Steel is known for its compatibility with welding processes, enabling the joining of different steel components or the repair of damaged steel structures. This property is crucial in numerous industries, including construction, automotive, and shipbuilding. Lastly, steel billets have a high level of recyclability. Steel is one of the most widely recycled materials globally, with a significant portion of steel production derived from recycled steel. This environmentally friendly aspect makes steel billets an excellent choice as they can be recycled and repurposed multiple times without losing their properties. In conclusion, steel billets possess high strength and durability, favorable heat transfer properties, excellent machinability and weldability, and a high level of recyclability. These properties establish steel billets as a versatile and extensively used material in various industries, spanning from construction and manufacturing to automotive and aerospace.

- Q:How are steel billets used in the manufacturing of construction machinery parts?

- Steel billets are an essential component in the manufacturing of construction machinery parts. These billets, which are semi-finished steel products, serve as the raw material from which various machinery components are formed. To start the manufacturing process, steel billets are first heated to a high temperature in a furnace, which helps to increase their malleability and facilitate further shaping. Once heated, the billets are then passed through a series of rollers and molds to form the desired shape and dimensions. Construction machinery parts such as gears, shafts, axles, and structural components require high strength and durability to withstand the rigorous demands of heavy-duty applications. Steel billets, being made from high-quality steel alloys, possess these desirable properties, making them ideal for manufacturing such parts. After the billets have been shaped, they undergo additional processes such as heat treatment and surface finishing to enhance their strength, hardness, and resistance to wear and corrosion. These treatments further improve the overall performance and longevity of the construction machinery parts. The use of steel billets in the manufacturing of construction machinery parts offers several advantages. Firstly, steel is known for its excellent mechanical properties, including high tensile strength and toughness, which are crucial for handling heavy loads and resisting impact and fatigue. Additionally, steel billets can be easily machined and welded, allowing for precise manufacturing and assembly of complex machinery components. Furthermore, steel is a versatile material that can be customized to meet specific requirements. By adjusting the composition and heat treatment processes, manufacturers can tailor the properties of the steel billets to suit the intended application of the construction machinery parts, ensuring optimal performance and durability. In conclusion, steel billets play a vital role in the manufacturing of construction machinery parts. Their high strength, durability, and versatility make them indispensable in producing components that can withstand the demanding conditions of construction sites. By utilizing steel billets, manufacturers can create reliable and long-lasting machinery parts that contribute to the overall efficiency and safety of construction projects.

- Q:What is the difference between hot-rolled and cold-rolled steel billets?

- The main difference between hot-rolled and cold-rolled steel billets lies in the manufacturing process. Hot-rolled steel billets are formed by heating the steel to a high temperature and then rolling it while it is still hot, resulting in a rougher and less precise surface finish. On the other hand, cold-rolled steel billets are formed by cooling the steel and then rolling it at room temperature, which produces a smoother and more precise surface finish. This difference in manufacturing process also affects the mechanical properties of the steel, with hot-rolled steel generally having higher tensile strength but lower dimensional accuracy compared to cold-rolled steel.

- Q:How are steel billets used in the manufacturing of slabs?

- Steel billets are an essential raw material used in the manufacturing of slabs. Slabs are large, flat pieces of steel that are used as a primary input in various industries, such as construction, automotive, and manufacturing. To produce slabs, the first step involves obtaining steel billets. These billets are semi-finished steel products that are typically obtained through the continuous casting process or by hot-rolling ingots. They are solid, rectangular or square-shaped blocks of steel with a cross-sectional area that can vary depending on the desired size and thickness of the slabs. Once the steel billets are obtained, they are heated to a high temperature to make them more malleable and easier to shape. This process, known as hot rolling, involves passing the billets through a series of rolling mills to progressively reduce their thickness and increase their length. The rolling mills apply intense pressure to the billets, causing them to elongate and acquire the desired dimensions. During the hot rolling process, the steel billets are often subjected to various manipulations, such as reheating and cooling, to ensure proper shaping and metallurgical properties. The billets may also go through additional processes, such as descaling (removing the oxide layer) and surface treatment, to enhance their quality and finish. Once the hot rolling process is completed, the steel billets are transformed into slabs. These slabs are then further processed to meet specific requirements. For instance, they may undergo additional rolling or reheating processes to achieve the desired thickness, dimensions, and surface finish. The slabs can also be cut into smaller pieces or further processed into different steel products, such as plates, sheets, or coils, depending on the intended use. In summary, steel billets play a crucial role in the manufacturing of slabs. They serve as the starting point for the production process, undergoing hot rolling and other treatments to transform them into the desired shape, size, and quality. The resulting slabs are then used as a primary input in various industries, contributing to the production of a wide range of steel products.

- Q:What are the different surface finishes available for alloy steel billets?

- There are several different surface finishes available for alloy steel billets, depending on the specific requirements and applications. Some of the common surface finishes include: 1. Hot rolled: This is the most common surface finish for alloy steel billets. It is achieved by rolling the steel billet at a high temperature, which results in a rough and scaled surface. 2. Cold drawn: This surface finish is achieved by pulling the steel billet through a die at room temperature. It provides a smooth and polished surface, with improved dimensional accuracy and surface quality. 3. Peeled: In this process, a layer of material is removed from the surface of the steel billet using a peeling tool. It results in a smooth and shiny surface finish, with improved surface quality and dimensional accuracy. 4. Ground: This surface finish is achieved by grinding the surface of the steel billet using abrasive wheels or belts. It provides a smooth and uniform surface finish, with improved surface quality and dimensional accuracy. 5. Turned: In this process, the steel billet is rotated against a cutting tool, which removes material from the surface and creates a smooth and polished finish. It is commonly used for high precision applications where a smooth surface finish is required. 6. Polished: This surface finish is achieved by polishing the steel billet using abrasive compounds and buffing wheels. It provides a mirror-like finish, with improved aesthetic appeal and corrosion resistance. It is important to select the appropriate surface finish based on the specific requirements of the application, such as dimensional accuracy, surface quality, aesthetic appeal, and corrosion resistance.

- Q:What are the different shapes of steel billets?

- Steel billets come in a variety of shapes and dimensions, depending on their intended use and production process. Some common shapes of steel billets include square, rectangular, round, and hexagonal. Square billets are typically used in the construction industry for making beams, columns, and other structural components. Rectangular billets are also used in construction but are often preferred for applications requiring a specific width-to-height ratio, such as window frames or door frames. Round billets are commonly used in the manufacturing of pipes, tubes, and shafts due to their symmetrical shape and ability to withstand torsional forces. Hexagonal billets, on the other hand, find applications in industries such as automotive and aerospace where their unique shape provides enhanced strength and stability. Overall, the shape of a steel billet is chosen based on the specific requirements of the final product and the manufacturing process involved.

- Q:What are the common shipping methods for steel billets?

- The common shipping methods for steel billets include sea transportation, rail transportation, and truck transportation.

- Q:Can steel billets be used in the production of sculptures and artwork?

- Yes, steel billets can be used in the production of sculptures and artwork. Steel is a versatile and malleable material that allows artists to create unique and intricate designs. The use of steel billets in sculptures and artwork offers durability, strength, and the potential for large-scale installations. Artists can shape, weld, and manipulate steel billets to create a wide range of sculptures, from abstract forms to figurative representations. The industrial aesthetic of steel can also add a contemporary and bold element to the artwork. Additionally, steel can be finished with various techniques such as painting, patina, or polishing, allowing artists to further enhance their creative vision. Overall, steel billets present an exciting opportunity for artists to explore and push the boundaries of their artistic expression.

- Q:What is the role of steel billets in the manufacturing of cutting tools?

- The manufacturing of cutting tools heavily relies on steel billets. These billets act as the primary material from which the cutting tool is forged or machined. Typically, steel billets are composed of high-quality steel alloys, which possess vital properties like hardness, toughness, and wear resistance that are necessary for cutting tools. To initiate the manufacturing process, the steel billets are heated to a specific temperature called the forging temperature. This temperature allows the steel to become malleable, making it easier to shape and mold into the desired cutting tool. The heated billets are then subjected to a forging process using specialized equipment, where they are struck or pressed to shape them into the desired form, such as drills, saws, or blades. Following the initial forging, the billets undergo further machining to refine their shape and dimensions. Machining processes like milling, turning, and grinding are employed to eliminate excess material, achieve precise dimensions required for the cutting tool, and create the desired cutting edge geometry. The quality of the steel billets used in the manufacturing process significantly impacts the performance and durability of the cutting tool. Steel billets with high carbon content and alloying elements like chromium, vanadium, or tungsten are often preferred as they enhance the hardness, strength, and wear resistance of the cutting tool. These properties are essential to ensure that the cutting tool can withstand the high forces, temperatures, and abrasive conditions it will encounter during use. In conclusion, steel billets serve as the foundation for manufacturing cutting tools. They provide the necessary raw material and properties required to create high-quality cutting tools that demonstrate exceptional performance, durability, and precision.

- Q:What are the factors that affect the quality of steel billets?

- There are several factors that can affect the quality of steel billets, including the composition of the raw material used, the temperature and duration of the melting process, the presence of impurities, the cooling rate during solidification, and the subsequent heat treatment processes. Other factors may include the equipment used for casting and rolling, the control of process parameters, and the overall quality management system in place.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords