Waterseal Mastic Double Sided Tape with Good Performance Equel to 2166

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC86 Tape

• KC 86 is a self-amalgamating mastic tape used for moisture sealing on all types of telecommunications and solid dielectric power cable splices and connections.

• It is a tacky, temperature stable mastic with excellent conformability and adhesion to metal and all types of cable insulations and jackets.

• It is put up on a white release coat separator in roll form without any core.

• Once applied, KC 86 mastic should be overwrapped with a vinyl or rubber tape which will encapsulate it and, throug centripetal force, make it into every crevice and indentation in a cable jacket thereby giving a superior moisture seal in a splice or aroun any connection.

• The tape is also RoHS compliant, resistant to corrosion, chemicals and salt water and has no adverse effect on cable insulations.

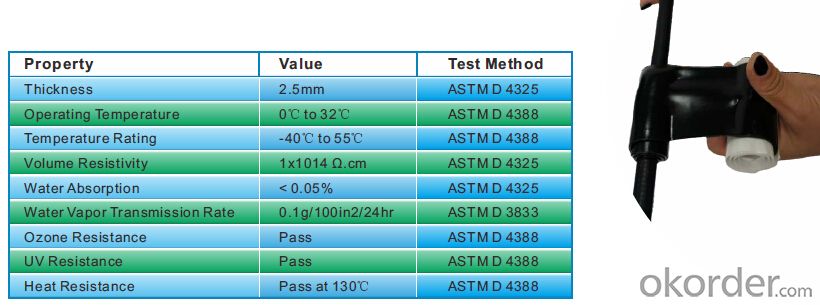

• Its 2.5mm thickness facilitates rapid protection build-up.

• Use in conjunction with KC 63 premium vinyl electrical tape for optimal performance.

Dimensions of KC86 Tape

2.5” x .1” x 23.6”

63mm(width) x 2.5mm(Thickness) x 0.6m(length)

Consult us for other sizes

Specifications of KC86 Tape

Applications of KC86 Tape

• Moisture seal and insulation in power cable through 600 volts

• Moisture seal and insulation of telecommunication cable connections in base stations, antennas and aerial feeders

• Other moisture sealing applications

FAQ

1.Before placing order, can we make sample firstly?

Sample can be arranged to send to you to test before placing order.

Sometimes sample is free ,sometimes sample charge should be included if more than 3 pcs with material .

But we are afraid freight charge will be paid by yourself.

Certainly, we will adjust additional sample and freight charges into your bulk order.

2.How can I get your sample?

Of course, we can send you some samples. Most samples are free, but sometimes we will take small sample fees.

Maybe you also send us your DHL or EMS/UPS/TNT etc account ,so you can pay for air freight to your carrier company directly.

3.Whether we can print our logo or need our color or size or not?

Yes, because we have our own factory and R&D team, so we can make products as your demands.

We can print your logo, we also can make as your size and print it as your color.

4.How many kinds of payment terms you can accept?

About payment terms, we would like 100%TT if less than $1000.00

Usually for bulk order , would like can be paid pay 30%- 50% advanced payment and the rest should be paid before dispatch.

We hope this information will be helpful to you, if you have any question, please feel free to contact us, we are always at your service.

- Q:A complete set of basement waterproof construction program

- Second, the basement of the external walls of water leakage construction preparation 2.1 Technical preparation 2.1.1 Selection of construction methods Waterproof engineering is related to the use of the project an important indicator, it is the construction process of a key project, difficult engineering. The choice of construction methods and programs has a direct impact on the quality of construction. The underground wall of the project SBS waterproofing membrane with hot melt method full construction. 2.1.2 before the start of the project, the first organization of engineering and technical personnel to enter the construction site, to understand the situation, to further understand the characteristics of the project to solve the contradiction between the construction technology and the implementation process. 2.1.3 technology before the end of the construction of waterproofing works by the professional foreman in accordance with the construction drawings and the existing national norms require the actual situation of the project to the construction team in writing to the end. The contents include construction site, construction sequence, construction technology, construction level, node fortification method, enhancement site and practice, project quality standard, guarantee the quality of technical measures. And after the field technical person in charge of the strict implementation of the audit.

- Q:How does the finished ventilator manufacturer waterproof?

- In the latest country set JJCJ33 clearly stipulates that the structure to be waterproof, refers to the internal ventilation of all nodes and ventilators and roof all the nodes,

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q:Roof membrane waterproof construction process, what should be noted that?

- Three do 1 to do concrete or mortar ratio is accurate 2 to do the surface of the second calendering 3 to be fully maintained

- Q:Slope roof drains do not need to be waterproof

- In addition, according to conventional settings vertical and horizontal sub-grid, complex structure easy to leak.

- Q:What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q:What are the key points and contents of the quality control of waterproof material?

- 1, polymer cement waterproof coating: it consists of a variety of water-based polymer emulsion and a variety of additives mixed with high-quality cement powder composition. Because of its high cost of polymer emulsion components (about 19,000 yuan / T), and the low cost of powder (about 800 yuan / T), it is because the liquid material, powder huge spread, the vast majority of fraud is to use 801 Glue + fossil powder + green dyestuff + cement blending; the other is to change the liquid material, the proportion of powder will be your liquid material consumption, as much as possible to increase the amount of powder. Resulting in poor waterproof coating adhesion, intolerance, after the completion of the finished product should not be too hard to pull down by hand, and was not much ductility of the sheet or even hand rub a few times into a powder, with blisters Will break down into small pieces. Can also be used to cut the finished product coating and then placed in the refrigerator freezer room after 8 hours to remove, gently forced to break will be broken, and the national standard requirements of the material to achieve low temperature flexibility -10 ℃.

- Q:Waterproof mortar expensive or dry mortar expensive

- Waterproof mortar more expensive. Because waterproof mortar compared to dry mortar, to add another waterproofing agent, emulsifier and other substances. Waterproof mortar regardless of the cost or transport are more cost-effective.

- Q:What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q:How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterseal Mastic Double Sided Tape with Good Performance Equel to 2166

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products