6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

C | Si | Mn | P | S | Ni | Cr | |

| SS304 | 0.046 | 0.316 | 1.481 | 0.0424 | 0.0028 | 8.001 | 18.019 |

| SS201 | 0.111 | 0.31 | 9.45 | 0.029 | 0.006 | 0.871 | 14.110 |

| SS316 | ≤0.08 | ≤1 | ≤2 | 0.035 | 0.03 | 1.0~14.0 | 16.0~18.5 |

Shape | Round / Square Etc. |

Brand | PEMCO/OEM/ODM |

Material | SS Stainless Steel 201, 304 , 316 |

Quality | First Grade |

Finish | Satin/Mirror |

Technology | Casting |

Certificate | ISO 9001-2000 |

Application | *Construction And Stair , Handrail , Railing Use |

*Shopping Mall,House,Outdoor | |

Feature | Beautiful Outlook, Easy To Clean, Low Maintenance Cost |

Usage | Widely Used On Stainless Steel Balustrade & Handrails, Indoor Or Outdoor Decorations,Etc. |

MOQ | 10 Pieces |

Delivery Time | 15-20 Days |

Colors for you to choose:

hot sale

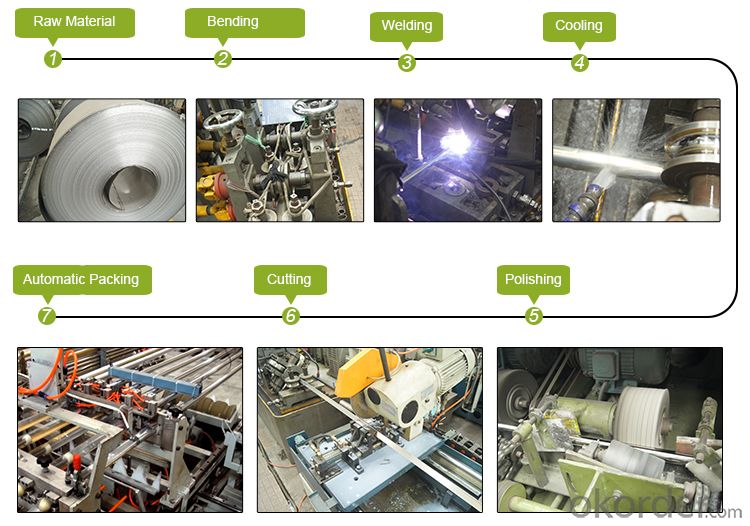

Production Process

Our Services

Pre-sale service:

1. Quotation: stainless steel pipe handrails price will be quoted according to material grade, size, thickness, length of each piece, finish and your quantity you want.

2. Sample: free samples can be sent for your reference.

3. OEM/ ODM Service: Your 2D/3D drawings or samples are welcome.

4. Other reasonable requests: factory photos, test reports, certifications, etc. to show.

Sale service:

1. Payment Method:

For samples, freight can be paid via Paypal, Westernunion or to our bank account.

Deposit and the balance can be paid via bank account or Alibaba Onetouch.

2. Business Term: EXW, FOB, CIF, etc.

3. Delivery: To door service - Internationl Express (DHL, FedEx, TNT, etc.)

Airport or shipping transportation

4. Payment and Shipping Terms:

Alibaba Onetouch Paypal Western Union Bank Transfer

- Q:Can stainless steel pipes be used for oil and gas refineries?

- Indeed, oil and gas refineries can utilize stainless steel pipes. Given its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate choice for the challenging and corrosive conditions typically encountered in refineries. It can endure substantial pressures, extreme temperatures, and the presence of diverse chemicals and corrosive elements frequently encountered in oil and gas operations. Moreover, stainless steel pipes provide outstanding protection against erosion, pitting, and cracking, guaranteeing the long-lasting integrity of the pipeline system.

- Q:What are the different types of stainless steel pipe couplings?

- There are several types of stainless steel pipe couplings, including threaded couplings, slip-on couplings, socket weld couplings, and butt weld couplings.

- Q:What are the different types of stainless steel pipe reducers?

- There are several different types of stainless steel pipe reducers available on the market. Some of the common types include: 1. Concentric Reducers: These reducers have a symmetrical design and are used to connect pipes of different diameters while maintaining a straight flow. They are most commonly used when there is a need to reduce the pipe size gradually. 2. Eccentric Reducers: Unlike concentric reducers, eccentric reducers have an offset design. They are used to connect pipes of different diameters while also changing the centerline of the pipe. This type of reducer is often used when there is a need to avoid trapping air or fluids in the piping system. 3. Swage Reducers: Swage reducers are a special type of reducer that is used to connect pipes of different diameters, typically in high-pressure applications. They are commonly used in oil and gas industries, as well as in chemical plants, where a smooth transition between different pipe sizes is required. 4. Threaded Reducers: These reducers have threaded ends, allowing them to be screwed onto pipes. They are commonly used in applications where a secure and leak-proof connection is required, such as in plumbing or gas systems. 5. Welded Reducers: Welded reducers are designed to be welded onto pipes. They are often used in applications where strength and durability are essential, such as in industrial settings or high-pressure systems. 6. Socket Weld Reducers: Socket weld reducers are similar to welded reducers but have a socket at one end, allowing them to be easily connected to pipes using a socket weld joint. They are commonly used in applications where a strong and reliable joint is required. It is important to choose the right type of stainless steel pipe reducer based on the specific application and requirements to ensure a proper and efficient connection between pipes of different sizes.

- Q:What are the different types of stainless steel pipe tees?

- Different applications and requirements call for various kinds of stainless steel pipe tees. 1. An equal tee is designed with three outlets of the same size, forming a 90-degree angle. It is commonly utilized to branch off or combine flow in a pipeline with equal diameters. 2. A reducing tee, as the name implies, has one outlet smaller than the other two. Its purpose is to connect pipes of different sizes, facilitating a seamless transition in fluid or gas flow. 3. In high-pressure or high-temperature applications, a barred tee provides additional support and reinforcement with a welded bar across the branch opening. This prevents stress concentration and potential failure. 4. For pipeline diversion or angled connections, a lateral tee with one outlet at a 45-degree angle is often employed. 5. A cross tee, featuring four outlets forming a cross-shaped configuration, is used when flow needs to be split or combined in multiple directions, primarily in complex piping systems. 6. Unions and socket weld tees have sockets or unions at the branch connection, allowing for easy disassembly and maintenance. They are commonly used when regular inspection, cleaning, or replacement is required. 7. Threaded tees have threaded branch connections that can be screwed onto the pipe without welding. They are frequently used in low-pressure applications or situations where frequent disassembly is necessary. Each type of stainless steel pipe tee offers specific advantages and is chosen based on the requirements of the particular piping system, including flow rates, pressure, temperature, and compatibility with the transported fluids or gases.

- Q:What is the difference between 904L and 316 stainless steel pipes?

- 904L and 316 stainless steel are commonly utilized materials in various industries for pipe manufacturing. The distinction between these two grades lies in their composition, properties, and applications. 1. Composition: - In terms of composition, 904L stainless steel contains elevated levels of chromium, nickel, and molybdenum, along with copper. It possesses a higher alloy content compared to 316 stainless steel. - On the other hand, 316 stainless steel, also referred to as marine grade stainless steel, contains significant amounts of chromium, nickel, and molybdenum. However, it does not include copper in its composition. 2. Corrosion Resistance: - In terms of corrosion resistance, 904L stainless steel exhibits remarkable resistance, particularly in aggressive environments like seawater and acidic conditions. Its high content of chromium, nickel, and molybdenum ensures superior protection against pitting and crevice corrosion. - Similarly, 316 stainless steel offers excellent corrosion resistance, especially in marine and chloride-rich environments. However, it is not as resistant to corrosion as 904L stainless steel. 3. Strength and Durability: - When considering strength and durability, 904L stainless steel demonstrates higher levels compared to 316 stainless steel due to its increased content of nickel and molybdenum. It can endure higher pressures and temperatures, making it suitable for applications in extreme conditions. - On the other hand, while 316 stainless steel possesses good strength and durability, it falls slightly behind 904L stainless steel in this regard. 4. Applications: - 904L stainless steel pipes find common usage in industries such as petrochemical, chemical processing, oil and gas, and marine applications. They prove ideal for environments with high chloride levels and acidic conditions. - Conversely, 316 stainless steel pipes are widely employed across various industries, including food processing, pharmaceuticals, architecture, and marine applications. They are suitable for general-purpose applications where corrosion resistance is required, but not as crucial as in aggressive environments. In summary, although both 904L and 316 stainless steel pipes provide corrosion resistance, 904L stainless steel showcases superior performance in aggressive environments owing to its higher alloy content. However, 316 stainless steel finds greater prevalence in general-purpose applications where an extremely high level of corrosion resistance is not essential.

- Q:Are stainless steel pipes suitable for semiconductor industries?

- Yes, stainless steel pipes are suitable for semiconductor industries. Stainless steel is widely used in various industries, including semiconductor manufacturing, due to its excellent properties. One of the main reasons stainless steel pipes are suitable for semiconductor industries is their high corrosion resistance. The semiconductor manufacturing process involves the use of various corrosive chemicals and gases. Stainless steel pipes are highly resistant to corrosion, ensuring that they can withstand the harsh environment and maintain their integrity over a long period of time. Additionally, stainless steel pipes have excellent mechanical properties, such as high strength and durability. This is crucial in semiconductor industries where the pipes need to withstand high pressure and temperature conditions. Stainless steel pipes can handle these demanding conditions without deformation or failure, ensuring the safety and efficiency of the semiconductor manufacturing process. Furthermore, stainless steel pipes have good cleanliness and hygienic properties. In semiconductor industries where cleanliness is essential to prevent contamination, stainless steel pipes are favored. They have a smooth surface, which prevents the accumulation of particles and facilitates easy cleaning and sterilization. Lastly, stainless steel pipes have good thermal conductivity. This property is important in semiconductor industries where temperature control is crucial. Stainless steel pipes can efficiently transfer heat, ensuring stable and precise temperature control during various manufacturing processes. In conclusion, stainless steel pipes are highly suitable for semiconductor industries due to their corrosion resistance, mechanical properties, cleanliness, and thermal conductivity. They provide reliable and efficient performance, making them a preferred choice for the demanding requirements of semiconductor manufacturing.

- Q:What is the difference between 904L and 2205 stainless steel pipes?

- 904L and 2205 stainless steel pipes differ in their composition and properties. 904L is a high-end austenitic stainless steel with low carbon content and high levels of nickel and molybdenum. It offers exceptional resistance to corrosion, especially in aggressive environments such as sulfuric acid. On the other hand, 2205 is a duplex stainless steel that combines the benefits of austenitic and ferritic stainless steels. It has a higher strength and better resistance to stress corrosion cracking compared to 904L. Additionally, 2205 has good resistance to pitting and crevice corrosion, making it suitable for applications in marine and chloride-containing environments. Overall, the choice between 904L and 2205 stainless steel pipes depends on the specific requirements of the application, including the level of corrosion resistance and mechanical properties needed.

- Q:What is the difference between a pipe and a tube in stainless steel applications?

- When it comes to stainless steel applications, the primary contrast between a pipe and a tube lies in their structural composition and intended use. A pipe is typically identified by its inner diameter (ID) and wall thickness, and its main purpose is to transport fluids or gases. It has a round shape and is commonly employed in industries such as oil and gas, chemical processing, and plumbing. Pipes can be manufactured using different methods, including seamless or welded processes. On the other hand, a tube is distinguished by its outer diameter (OD) and wall thickness, and it is commonly used for structural or mechanical purposes. Tubes can have various shapes, including round, rectangular, or square, and they are frequently utilized in industries such as construction, automotive, and aerospace. Tubes can also be produced through seamless or welded methods. Regarding manufacturing, pipes generally undergo stricter tolerances and quality control measures due to their transportation function, while tubes may have less stringent requirements as they are primarily used for structural applications. Additionally, pipes are commonly measured and sold by their nominal sizes, whereas tubes are typically specified by their actual dimensions. Both pipes and tubes can be made from stainless steel, which provides excellent corrosion resistance and durability. Stainless steel is a versatile material that is suitable for a wide range of applications, including those requiring high temperatures or exposure to harsh environments. In summary, the main difference between a pipe and a tube in stainless steel applications is their intended purpose and structural characteristics. Pipes are designed for fluid or gas transportation, while tubes are utilized for structural or mechanical applications.

- Q:Can stainless steel pipes handle high-velocity fluid flow?

- High-velocity fluid flow can indeed be handled by stainless steel pipes. Renowned for their remarkable strength, durability, and corrosion resistance, stainless steel pipes are well-suited for managing high-velocity fluid flow. They possess the ability to endure the pressure and turbulence created by swiftly moving fluids. Moreover, the smooth inner surfaces of stainless steel pipes reduce friction and aid in sustaining the velocity of the fluid flow. As a consequence, stainless steel pipes find widespread application in industries like oil and gas, chemical processing, and power generation, where encounters with high-velocity fluid flow are frequent.

- Q:Can stainless steel pipes be used for mining and mineral processing applications?

- Yes, stainless steel pipes can be used for mining and mineral processing applications. Stainless steel is known for its excellent corrosion resistance and durability, making it suitable for handling various corrosive and abrasive materials found in mining and mineral processing operations. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them a reliable choice for transporting fluids and slurries in these applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords