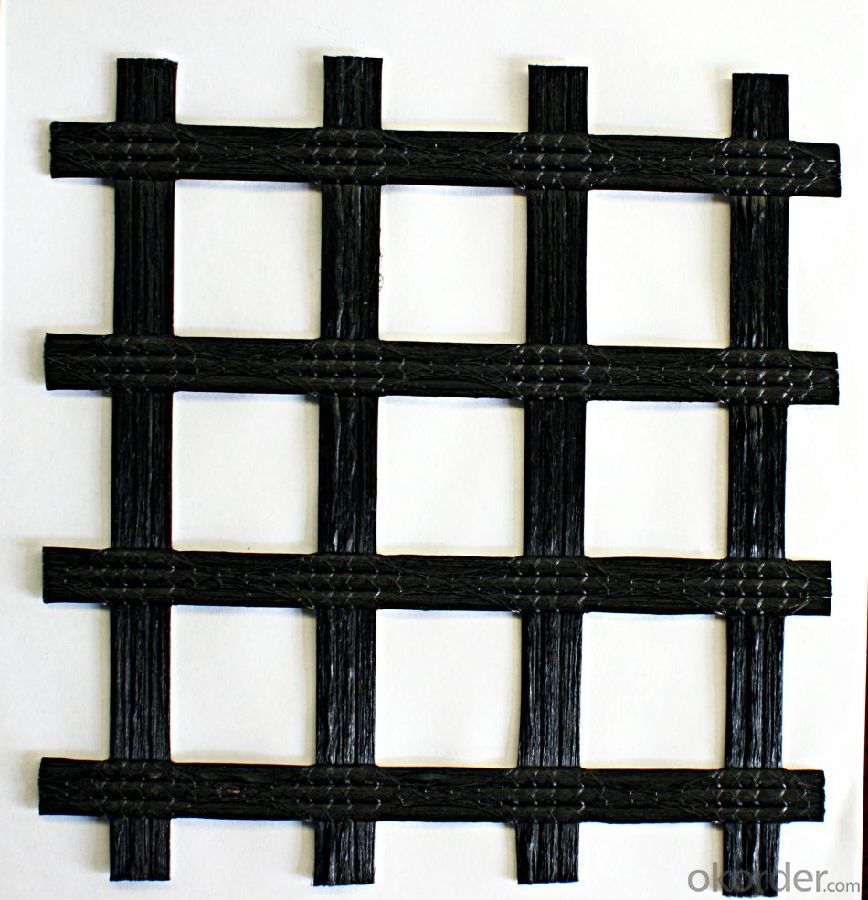

High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Polyester Geogrid known as PET Grid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

PET Grid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the advantages of using geogrids?

- Geogrids offer several advantages in various applications. Firstly, they provide enhanced stability and load-bearing capacity to soil structures, reinforcing them and preventing slope erosion or ground movement. Secondly, geogrids are highly durable and resistant to environmental factors such as UV radiation and chemical degradation, ensuring long-term performance. Additionally, they can be easily installed, reducing construction time and costs. Geogrids also facilitate drainage by allowing water to flow through their apertures, preventing water buildup and maintaining soil integrity. Lastly, they are versatile and can be used in a wide range of applications, including road and railway construction, retaining walls, and landfill lining, making them a reliable solution for geotechnical engineering projects.

- Q:Are there any design guidelines for using geogrids in reinforcement applications?

- Yes, there are design guidelines available for using geogrids in reinforcement applications. These guidelines provide recommendations for selecting the appropriate geogrid type, determining the required strength and stiffness properties, and specifying the proper installation methods. The guidelines also outline factors such as soil characteristics, loading conditions, and project requirements that need to be considered in the design process. Adhering to these guidelines ensures the effective and efficient use of geogrids in reinforcement applications.

- Q:What is the width of glass fiber grating 100cm

- Glass fiber reinforced plastic (FRP) grid is a kind of board material with a lot of space, which is made of glass fiber as reinforcing material and unsaturated polyester resin as matrix.

- Q:Anchorage length of Geogrid

- Glass fiber geogrid layer(1) pavement surfaceA. of the new asphalt concrete pavement, glass fiber grid can be placed on the semi rigid base and under seal, can be placed between the seal and the asphalt.

- Q:Classification and application of polyethylene geogrid?

- Polyethylene geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- Q:What is the use of glass fiber grille paving asphalt road

- Silicon oxide is an inorganic material, its physical and chemical properties are very stable, and has the advantages of high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep

- Q:What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the type of geogrid and the specific temperature range. In general, higher temperatures can cause geogrids to expand and become more flexible, potentially increasing their tensile strength and allowing them to better distribute loads. However, extreme temperatures can also lead to thermal degradation and reduced performance. It is important to consider the intended application and temperature conditions when selecting geogrids to ensure optimal performance and longevity.

- Q:Can geogrids be used in reinforcement of geosynthetic clay liners?

- Yes, geogrids can be used in the reinforcement of geosynthetic clay liners (GCLs). Geogrids are often used as a reinforcement material to enhance the tensile strength and stability of the GCLs, thereby improving their performance in applications such as slope stabilization, landfill liners, and erosion control. The geogrids are typically placed between layers of GCLs to provide additional support and prevent potential failure modes, such as shear sliding or lateral spreading.

- Q:How to effectively control the quality of Geogrid in the process of construction

- 2 the surface of the bearing surface of the geosynthetics shall be leveled and compacted, and the hard and protruding surface shall be removed.

- Q:What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the subgrade by removing any vegetation or loose soil, and then compact the subgrade to achieve a stable base. The geogrid should be unrolled and placed on top of the prepared subgrade, ensuring it is stretched and anchored securely at the edges. Overlapping the geogrid panels by the manufacturer's recommended amount and using connector devices may be necessary. Finally, the geogrid should be covered with an appropriate fill material and compacted in layers to ensure proper integration and load distribution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords