Light High Alumina Refractory Insulating Bricks for Rotary Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for High Alumina Fire Brick:

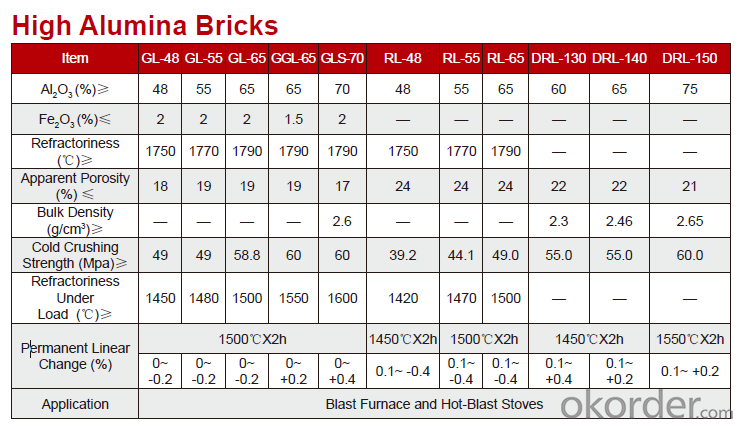

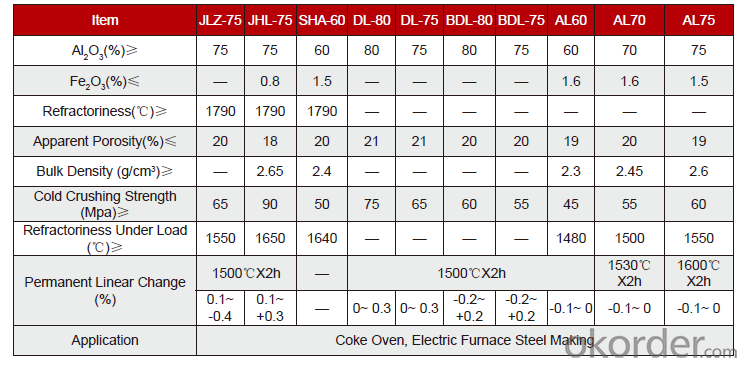

CNBM High Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%. The kiln shell is made from rolled mild steel plate, usually between 15 and 30 mm thick, welded to form a cylinder which may be up to 230 m in length and up to 6 m in diameter. This will be usually situated on an east/west axis to prevent eddy currents.

Upper limits on diameter are set by the tendency of the shell to deform under its own weight to an oval cross section, with consequent flexure during rotation. Length is not necessarily limited, but it becomes difficult to cope with changes in length on heating and cooling (typically around 0.1 to 0.5% of the length) if the kiln is very long.

Product Applications:

CNBM High Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Product Advantages:

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Main Product Features:

◆Low thermal conductivity

◆Excellent acid and base slaging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

Product Specifications:

FAQ:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:High alumina brick 80 with which high aluminum cement?

- Which kind should be chosen should be determined according to the conditions of use, life expectancy and cost control. By the way, the quality of masonry is also very influential.

- Q:Application characteristics of high alumina brick

- Slag resistance. Due to the high alumina brick products in the three oxidation of two aluminum is neutral and high content, so this material products for acid-base slag corrosion resistance.

- Q:What is the difference between fireclay bricks and high alumina refractory bricks?

- High R.U.L, low creep high alumina brick [1] is using high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q:Difference between low creep high alumina brick and ordinary high alumina brick

- Low creep and high alumina brick is based on the theory of "three stones". The combination of bauxite and clay as the main raw material, adding kyanite, andalusite and sillimanite, commonly known as the "three stone" control, physicochemical index and size composition, using alumina mullite corundum + + raw materials such as technical scheme. In the production process, first to detect and control indexes of raw materials, crushing, grinding, sieving process, according to the distribution ratio of ingredients, the size and moisture control of mud mixing after to meet the requirements of forming and molding machine, the use of qualified abrasives, blow molding control number, size and flash at the same time, the detection efficiency of semi-finished products and meet the requirements. Production process: high temperature calcination of high-grade alumina, adding small creep rate of high temperature materials, by high-pressure molding and high temperature firing. It has the characteristics of high strength, low creep rate and high use temperature. Widely used in high temperature furnace, hot air furnace hearth lining, brick and so on.

- Q:What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q:What is the high temperature limit of refractory bricks and refractory soil?

- Refractory bricks are stone powder and clay paste. They are fired in a kiln of 1300 degrees. The upper limit is 1500 degrees above normal pressureRefractory bricks - refractory materials of a specified shape and size.

- Q:What is fireproof concrete?

- Silicate fireproof heat-resistant concrete using temperature can reach 700 DEG ~800 DEG, the main mechanism of its heat is dehydrated calcium hydroxide silicate hydrates series of cement clinker under high temperature, the calcium oxide and slag and mixing activated silica material in the three and two aluminum oxide and the reaction of anhydrous calcium silicate and anhydrous aluminum acid calcium has strong heat resistance, the fire resistance of concrete is a certain. Such as the use of high alumina bauxite and broken bricks, magnesia brick and magnesia for fireproof heat-resistant concrete materials with the highest using temperature can reach 1100 DEG C.

- Q:What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q:The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

- Q:Does the chimney have high acid resistance?

- If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light High Alumina Refractory Insulating Bricks for Rotary Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords