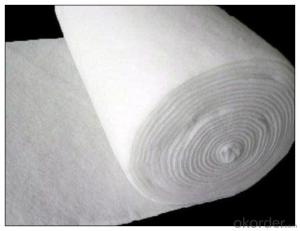

Needle Punched Non Woven Polypropylene Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

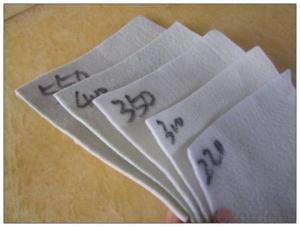

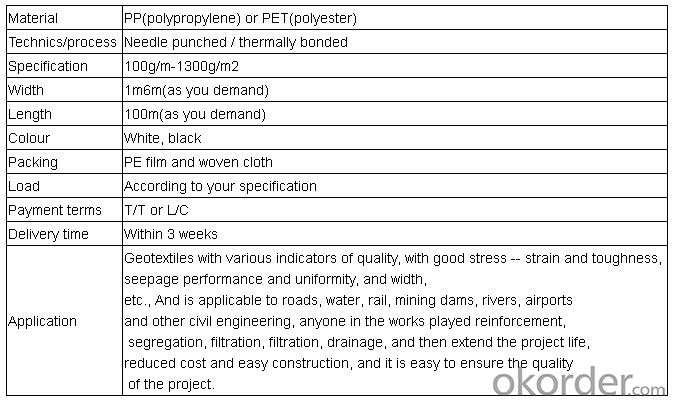

Specifications of Polypropylene geotextiles for River Construction:

1, Biggest Width: 6meter

2, Weight: about 1000gsm

3, Treatment: UV protect

Application of Polypropylene geotextiles for River Construction:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

Specification of Polypropylene geotextiles for River Construction:

Functions and Features Polypropylene geotextiles for River Construction:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the factors affecting the selection of geotextiles?

- The factors affecting the selection of geotextiles include the type and severity of the application, desired performance characteristics such as strength and filtration properties, site conditions such as soil type and slope stability, environmental considerations such as chemical resistance and durability, and cost-effectiveness.

- Q:Geotextile price is how much money

- Ask the geotextile price is too general, because the standard too much. Short wire, filament, polyester; non-standard, GB and so on. To Hongxiang Li Qian short wire geotextile price quote, for example, the price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan /Ton. 187 & lt; 6600 & lt; 5604

- Q:Geotextile with ordinary non-woven like not? The

- Geotextile is divided into acupuncture cloth and woven fabrics, and some places geotextile also known as non-woven fabrics

- Q:What are the different geotextile installation guidelines?

- The different geotextile installation guidelines include proper site preparation, ensuring the soil is smooth and free of debris, anchoring the geotextile securely to prevent movement, overlapping the geotextile to ensure complete coverage, and using appropriate techniques for joining and sealing the geotextile. Additionally, it is crucial to follow manufacturer instructions and consult with an engineer for specific project requirements.

- Q:What are the key considerations for geotextile installation in high water flow areas?

- The key considerations for geotextile installation in high water flow areas include selecting a geotextile with the appropriate filtration and hydraulic properties, ensuring proper anchoring and securing of the geotextile to prevent movement or displacement, maintaining proper overlap and seam integrity to maximize effectiveness, and considering factors such as soil conditions, potential erosion, and durability of the geotextile in high flow conditions.

- Q:What are the different installation methods for geotextiles?

- There are several installation methods for geotextiles depending on the specific application and project requirements. Some common methods include loose-laid, anchored, and mechanically stabilized installation. In the loose-laid method, the geotextile is simply placed on the ground surface without any additional fixation. Anchored installation involves securing the geotextile to the ground using stakes, pins, or other fasteners. Mechanically stabilized installation utilizes heavy machinery or equipment to mechanically compact the geotextile into the ground. The choice of installation method depends on factors such as soil conditions, project specifications, and desired performance outcomes.

- Q:How do geotextiles contribute to soil reinforcement?

- Geotextiles contribute to soil reinforcement by providing a stable and durable layer that helps to distribute loads and reduce soil erosion. They act as a barrier against the movement of soil particles, preventing soil erosion and maintaining the stability of the soil structure. Additionally, geotextiles can improve the tensile strength of the soil, increasing its load-bearing capacity and overall stability.

- Q:What are the considerations for geotextile selection in mining operations?

- There are several considerations for geotextile selection in mining operations. Firstly, the geotextile should have high tensile strength and puncture resistance to withstand the heavy machinery and equipment used in mining. It should also have excellent filtration properties to prevent soil erosion and allow for proper drainage. Additionally, the geotextile should be chemically resistant to withstand the harsh chemicals and contaminants often found in mining operations. Lastly, cost-effectiveness and ease of installation should also be taken into account to ensure the overall efficiency and success of the mining project.

- Q:How do geotextiles help in separating different soil layers?

- Geotextiles help in separating different soil layers by acting as a barrier between the layers, preventing their intermixing. The geotextiles have a permeable structure that allows water to pass through while retaining the soil particles, thus maintaining the integrity of each layer. This separation is crucial in various applications, such as road construction, landscaping, and erosion control, as it enhances the stability and performance of the soil layers.

- Q:What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include requirements for the material's strength, permeability, filtration properties, and durability. These specifications ensure that the geotextile can effectively separate soil particles from the drainage media, prevent clogging, and maintain its functionality over time. Additionally, the specifications may also address the geotextile's dimensions, weight, and installation guidelines to ensure proper performance in subsurface drainage applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

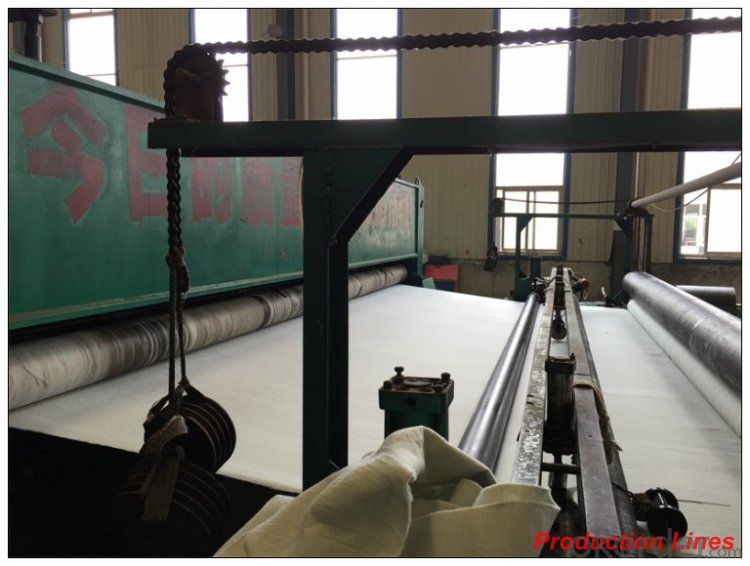

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Needle Punched Non Woven Polypropylene Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords