PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PP Caps Color Coated Aluminium Coils New Year Promotion

l Product Information

1. Type:Aluminum Coil

2. Alloy: 8011

3. Temper: H24/14

4. Thickness: 0.21mm

5. Width: 100-2500mm or as your request

6. Length: produce as your request

7. Weight: produce as your request

8. Color: One side with colored lacquer and the other side with transparent lacquer or both sides with transparent lacquer.

9. Application: The coated aluminum coil with variety colors widely used on the production of caps, such as wine bottle cap, medicinal liquid lids and cosmetic caps.

10. Surfure: Smooth, clean, be free of scratch and corrosion

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

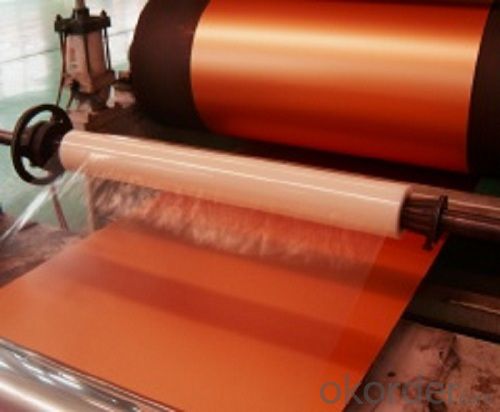

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:What are the different surface treatments for aluminum coils?

- There are several different surface treatments available for aluminum coils, each offering unique properties and benefits. Some common surface treatments for aluminum coils include: 1. Mill Finish: This is the untreated, raw surface of aluminum coils that comes directly from the mill. It has a slightly rough texture and is typically used in applications where aesthetics are not a primary concern. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum coil. This treatment enhances corrosion resistance, improves durability, and provides a wide range of color options. 3. Painted Finish: Aluminum coils can be coated with various paint systems to enhance their appearance and protect against corrosion. Painted finishes offer a wide range of colors, gloss levels, and textures, allowing for customization according to specific design requirements. 4. Polished Finish: Polishing is a mechanical process that creates a smooth and reflective surface on the aluminum coil. This treatment is often used in decorative applications, where a high-quality and aesthetically pleasing finish is desired. 5. Brushed Finish: Brushing involves mechanically brushing the surface of the aluminum coil to create a pattern of fine parallel lines. This treatment provides a unique texture and is commonly used in architectural and interior design applications. 6. Embossed Finish: Embossing is a process of creating raised or recessed patterns on the surface of the aluminum coil. This treatment adds texture, enhances strength, and can be used for decorative purposes or to improve grip in certain applications. 7. Laminated Finish: Lamination involves applying a layer of protective film or coating on the surface of the aluminum coil. This treatment provides additional protection against scratches, abrasion, and UV rays, making it suitable for outdoor applications. Each surface treatment option has its own advantages and is chosen based on the specific requirements of the application, such as corrosion resistance, durability, aesthetics, and functionality.

- Q:How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils find widespread use in the manufacturing of appliances because of their unique properties and versatility. Primarily, they are employed in the production of heat exchangers, which serve as essential components in appliances like refrigerators, air conditioners, and heaters. One of the key advantages of aluminum coils lies in their remarkable thermal conductivity. This attribute enables them to efficiently transfer heat from one area to another, making them an ideal choice for applications involving heat exchange. In appliances, aluminum coils assist in the cooling or heating processes by transferring heat between the refrigerant or coolant and the surrounding air or water. Additionally, aluminum coils offer superior corrosion resistance in comparison to other metals, rendering them highly suitable for appliances that come into contact with moisture or other corrosive substances. This property guarantees the durability and longevity of the appliances, as the coils are less likely to rust or corrode over time. Moreover, the lightweight nature of aluminum coils contributes to the overall efficiency of appliances. It reduces the energy required for transportation and installation, thereby making it a more sustainable option. Furthermore, the lightweight coils allow for more compact designs, maximizing space utilization in appliances. Another advantage of aluminum coils is their malleability. They can be easily shaped and formed into various sizes and configurations, enabling customized designs that cater to specific appliance requirements. This design flexibility empowers manufacturers to create efficient heat exchangers that fit within the limited space available in appliances. In conclusion, the excellent thermal conductivity, corrosion resistance, lightweight nature, and malleability of aluminum coils make them a preferred choice for use in appliances. These properties make them particularly well-suited for heat exchangers, which play a crucial role in appliances requiring efficient cooling or heating processes.

- Q:I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- Aluminum Foil Safety

- Q:Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum is a versatile and widely-used material in various industries, including electronics. Aluminum coils are often used in the construction of transformers, inductors, and other components of electronic devices. One of the main advantages of using aluminum coils in electronic devices is their lightweight nature. Aluminum is much lighter than other commonly used materials like copper, which makes it easier to handle and transport. Additionally, aluminum has good thermal conductivity, allowing for efficient heat dissipation within electronic devices. Furthermore, aluminum coils are resistant to corrosion, which is crucial in electronic applications where the devices may be exposed to moisture or other harsh environments. This corrosion resistance helps to prolong the lifespan of the electronic device and ensures its reliability. Moreover, aluminum coils can be easily formed into various shapes and sizes, making them suitable for different electronic device designs. They can be customized to meet specific requirements, such as fitting into compact spaces or achieving specific electrical characteristics. Overall, aluminum coils offer several advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, corrosion resistance, and flexibility in design.

- Q:How are aluminum coils used in the production of medical equipment?

- Aluminum coils are commonly used in the production of medical equipment due to their excellent conductivity, lightweight nature, and corrosion resistance. These coils are primarily utilized in various medical devices such as MRI machines, X-ray equipment, and ultrasound scanners. Aluminum coils are used in these applications for their ability to efficiently dissipate heat, transmit electrical signals, and provide structural support. Additionally, the flexibility of aluminum coils allows for easy customization and shaping to meet the specific design requirements of medical equipment.

- Q:What is the typical coefficient of friction for aluminum coils?

- The typical coefficient of friction for aluminum coils can vary depending on various factors such as the surface conditions, lubrication, and the specific type of aluminum alloy used. However, in general, the coefficient of friction for aluminum coils is relatively low compared to other materials. It typically falls within the range of 0.1 to 0.4.

- Q:i want to save some money on my electricity bill, and i heard that aluminum foil rejects the heat that goes through the windows, also does it work with the cold?

- Aluminum foil on windows looks really tacky and also raises suspicion that you could be growing marijauna in the house. It would tick off the neighbors because it looks really tacky. You can buy a clear cellophane type product designed for this purpose at the local hardware or building store.

- Q:Can aluminum coils be used in food processing equipment?

- Indeed, food processing equipment can utilize aluminum coils. The numerous advantageous properties of aluminum make it a favored option for food-related applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity render aluminum coils appropriate for deployment in refrigerators, freezers, ovens, and heat exchangers within the realm of food processing equipment. Furthermore, aluminum is non-toxic and does not interact with food, thereby establishing it as a secure material for direct interaction with consumable items. Nevertheless, it remains crucial to verify that the aluminum employed in food processing equipment adheres to the requisite food safety standards and regulations, thereby averting any potential contamination.

- Q:What type of equipment is used to process aluminum coils?

- The equipment employed for aluminum coil processing varies depending on the specific manufacturing process and requirements. Nevertheless, there are several common types of equipment used in this process: 1. Uncoilers/Decoilers: These machines are utilized to unroll and straighten the aluminum coils, facilitating further processing. 2. Levelers: Leveling machines are employed to flatten the surface of the aluminum coil, ensuring it is even and flat before proceeding with additional processing. 3. Slitters: Slitting machines are used to cut the aluminum coil into narrower strips of desired widths. This equipment finds frequent use in industries such as automotive, construction, and packaging. 4. Shears: Shearing machines are employed to cut the aluminum coil into specific lengths or shapes required for the manufacturing process. 5. Roll Forming Equipment: Roll forming machines shape the aluminum coil into specific profiles or designs. Commonly employed in the construction industry, they are used to manufacture roofing panels, gutters, and siding. 6. Heat Treatment Furnaces: Heat treatment furnaces subject the aluminum coil to specific temperature conditions to enhance its strength, hardness, or other desired properties. 7. Surface Treatment Equipment: Various equipment, including cleaning machines, chemical baths, and coating lines, are used for surface treatment processes such as cleaning, anodizing, or painting the aluminum coil. These processes improve the coil's appearance, corrosion resistance, or other functional properties. 8. Packaging Equipment: Packaging machines are employed to bundle, wrap, or pack the processed aluminum coils for storage, transportation, or further distribution. It is crucial to note that the specific equipment used may vary depending on factors such as size, thickness, alloy, and intended use of the aluminum coils. Manufacturers often utilize customized equipment to meet their specific requirements and ensure efficient processing.

- Q:What are the different coil packaging materials used for aluminum coils?

- Some common coil packaging materials used for aluminum coils include wooden pallets, steel strapping, stretch film, and cardboard edge protectors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords