Cold rolled grain oriented silicon steel wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62134 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing products, unexposed construction products, as well as many other areas of manufacturing

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

| ||||

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

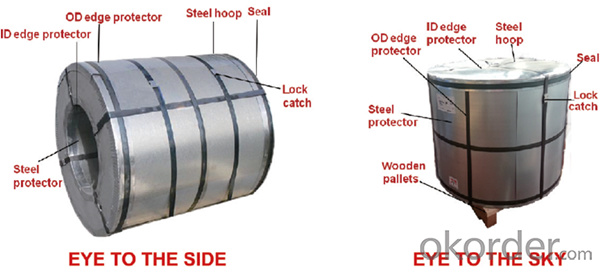

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q:I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- Cold Steel makes the best and strongest swords around, ever cut through a steel car hood? Their swords can, I would suggest that if you but one, to also get yourself some life insurance... these things are incredible.

- Q:How are steel coils used in the manufacturing of heat shields?

- Steel coils are used in the manufacturing of heat shields to provide a durable and sturdy base material that can withstand high temperatures. The coils are formed into a specific shape and then coated with heat-resistant materials to create a protective barrier against heat and flames.

- Q:Can steel coils be perforated?

- Yes, steel coils can be perforated. Perforation is the process of creating small holes or punctures in a material, and steel coils can undergo this process to achieve specific purposes such as enhancing ventilation, improving drainage, or creating decorative patterns.

- Q:What is the weight range of steel coils?

- The weight range of steel coils varies depending on the specific type and dimensions, but they generally range from a few hundred kilograms to several tonnes.

- Q:How do steel coils contribute to strength and stability in structures?

- Steel coils are vital components in numerous structures due to their significant impact on strength and stability. The exceptional strength of steel itself makes it renowned, as it can resist large amounts of tension without breaking or deforming. When steel is shaped into coils, its strength is further enhanced by evenly distributing the load across the entire structure. This even distribution of force prevents localized stress concentrations, enabling the structure to withstand heavy loads and external pressures more effectively. Furthermore, steel coils provide stability to structures by offering rigidity and resistance against deformation. Steel is known for its stiffness, preventing excessive flexing or bending under loads. The tightly wound coils create a robust and compact structure that can efficiently resist dynamic forces like wind, earthquakes, or vibrations. This resistance to deformation minimizes potential damage, ensuring the structure's stability and integrity. Moreover, steel coils also contribute to the durability and longevity of structures. Steel exhibits remarkable durability, being highly resistant to corrosion, rust, and deterioration over time. This longevity ensures that structures built with steel coils can remain strong and stable for extended periods, requiring minimal maintenance or repairs. Additionally, steel coils offer versatility in design and construction. The ability to shape steel into various coil sizes and configurations allows for customization based on specific structural requirements. Architects and engineers can utilize steel coils to create complex structures while maintaining their strength and stability. This versatility allows for innovative and efficient design solutions, making steel coils the preferred choice in many construction projects. In conclusion, steel coils play a crucial role in enhancing the strength and stability of structures. The inherent strength of steel, combined with the unique design of coils, provides structures with the necessary rigidity, resistance to deformation, and durability. Additionally, the versatility of steel coils allows for customization and innovative design solutions. Overall, steel coils significantly contribute to the overall integrity and longevity of structures, making them an essential component in the construction industry.

- Q:What are the common uses of cold rolled steel coils?

- Cold rolled steel coils are commonly used in a variety of industries and applications. They are frequently utilized in the automotive industry for manufacturing parts such as automobile bodies, frames, and components. Cold rolled steel coils are also widely employed in construction for producing structural components, roofing, and siding. Additionally, they are used in the manufacturing of appliances, furniture, and various electrical products. The smooth and consistent surface of cold rolled steel coils makes them ideal for applications that require a high-quality finish, such as in the production of kitchen utensils and decorative items.

- Q:How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they are processed and shaped into various structural components like beams, plates, and girders. These coils are first uncoiled and then cut, rolled, and welded to create the required bridge sections. The high strength and durability of steel make it an ideal material for bridges, and the use of steel coils allows for efficient and precise manufacturing of these vital infrastructure elements.

- Q:What are the different types of steel coil storage systems used during processing?

- There are various types of steel coil storage systems used during processing, including coil racks, coil cradles, coil saddles, coil blocks, and coil pads. These systems provide a safe and organized way to store steel coils, ensuring easy access, efficient handling, and minimizing the risk of damage.

- Q:How do steel coils compare to other materials?

- Steel coils have several advantages over other materials. Firstly, steel is known for its high strength and durability. This makes steel coils highly resistant to wear and tear, making them suitable for a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for use in high-temperature environments. Furthermore, steel coils have superior corrosion resistance compared to many other materials. This is especially important in industries such as construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another advantage of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. This makes steel coils suitable for a wide range of applications, including manufacturing, construction, transportation, and energy industries. Moreover, steel coils offer good value for money. Despite their numerous benefits, steel coils are generally more affordable compared to other materials such as aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries looking for high-quality and reliable materials. In summary, steel coils have several advantages over other materials. They offer high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and can be easily customized to suit different applications. Additionally, they provide good value for money. Overall, steel coils are a reliable and efficient choice for various industries and applications.

- Q:so what is stronger tempered steel Blade or carbon steel Blade? a Machete made of those i said above what will last longer,what can cut better,which will will shatter first.

- 1. all steel blades are tempered, whether they are high carbon blades or low carbon blades. 2. It depends on what kind of steel they are made from. So im going to answer this question, using the following qualifications. 440A stainless steel 440C stainless steel - high carbon. The higher the carbon level, the more brittle a blade becomes. But the higher the carbon level, will increase a steel’s wear resistance , meaning it will have a better edge retention 2. They both will work well. Pros's / Con's The 440C blades will need less sharpening, but are harder to sharpen The 4401 blades will need to be sharpened more, but are far easier to resharpen. So it basically comes down to where you will be using them and how you will be using them. If your gonna be out in the middle of the jungle and stopping for the night, then the high carbon blade would probably be better, you use it all day, resharpen it at night. If your gonna be cutting brush, tobbaco, etc on your land, then the 440A would be better, because you can take a couple of min's to resharpen it often

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold rolled grain oriented silicon steel wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62134 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords