Cold rolled steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

The raw material of cold rolled steel coil/sheet is high quality hot rolled product. Cold rolled steel coil/sheet as defined in the EN 10130/98 standard, with guaranteed maximum mechanical characteristics and guaranteed minimum ductility and formability.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

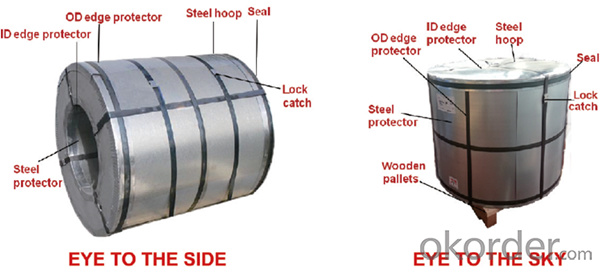

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q:How are steel coils inspected for surface defects using non-destructive testing methods?

- Steel coils are inspected for surface defects using non-destructive testing (NDT) methods to ensure their quality and integrity. There are several common NDT methods employed in this process. One of the most widely used methods is visual inspection, where trained inspectors visually examine the surface of the steel coils for any visible defects such as scratches, cracks, pits, or corrosion. This method is relatively simple and cost-effective but is limited to detecting only surface-level defects. Another commonly used NDT method is magnetic particle testing (MT). This method utilizes the principles of magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. A magnetic field is applied to the steel coil, and iron particles are applied to the surface. If there is a defect, such as a crack or discontinuity, the iron particles will concentrate around it, making the defect visible to the inspector. Liquid penetrant testing (PT) is another NDT method used to inspect steel coils for surface defects. In this method, a liquid penetrant is applied to the surface of the coil. The penetrant is drawn into any surface defects by capillary action. After a certain period, excess penetrant is removed, and a developer is applied. The developer draws out the penetrant from any defects, making them visible to the inspector. Ultrasonic testing (UT) is a widely used NDT method that can detect both surface and subsurface defects in steel coils. High-frequency sound waves are transmitted into the steel coil, and the reflected waves are analyzed to identify any abnormalities. This method can detect defects such as cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method used for inspecting steel coils. This method utilizes electromagnetic induction to detect surface and near-surface defects. A coil carrying an alternating current is placed near the surface of the coil being inspected. Any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed, allowing the inspector to identify and evaluate the severity of the defects. In conclusion, steel coils are inspected for surface defects using various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

- Q:Is sterling silver better than surgical steel as far as being hypoallergic in earrings? If I have a choice which should I get? Thanks!

- Surgical steel.

- Q:What are the common methods of slitting steel coils?

- There exists a variety of methods for slitting steel coils, each possessing their own distinct advantages and applications. 1. Rotary Shear Slitting: This technique utilizes rotary cutting knives to separate the steel coil. The coil is passed through the rotary shear machine, and the knives make simultaneous cuts along the coil's length. Rotary shear slitting is renowned for its high-speed operation and ability to handle thicker gauge materials. 2. Loop Slitting: Loop slitting involves introducing the steel coil into a looping pit, creating a loop of material. The loop is then pulled through a set of knives that make the cuts. This particular approach is commonly employed for thin gauge materials, providing precise cuts with minimal burr. 3. Drag Slitting: In drag slitting, the steel coil is fed through a series of driven rolls or drag pads, which maintain tension on the material. The coil is then guided through circular knives that perform the slits. Drag slitting is suitable for various steel gauges and offers good accuracy and edge quality. 4. Crush Slitting: Crush slitting entails passing the steel coil through a set of rolls, with one roll being rubber-covered and the other being hard. The rubber roll compresses the material against the hard roll, resulting in the slits. This method is commonly utilized for thin gauge or delicate materials, as it minimizes the risk of edge damage. 5. Laser Slitting: Laser slitting employs a high-powered laser beam to make precise cuts on the steel coil. This method is highly accurate and enables complex slitting patterns and narrow width cuts. Laser slitting is frequently utilized for high-end applications that demand superior edge quality. Each of these methods possesses unique advantages and is selected based on factors such as material thickness, desired edge quality, production speed, and cost considerations. It is crucial to meticulously select the appropriate slitting method to ensure the desired outcome and efficiency in steel coil processing.

- Q:What are the dimensions of steel coils used in the storage tank industry?

- The dimensions of steel coils used in the storage tank industry can vary depending on the specific requirements of the tank being manufactured. However, in general, steel coils used for storage tanks are typically available in various sizes and thicknesses. The width of steel coils can range from around 600 millimeters to 2,400 millimeters, while the length can vary from several meters to tens of meters. The thickness of the coils can also vary, typically ranging from 1.5 millimeters to 10 millimeters or more. These dimensions are determined by factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank. The specific dimensions for a given storage tank project would be determined by the tank manufacturer or designer, in accordance with industry standards and specific project specifications.

- Q:What are the common methods of storing steel coils in warehouses?

- There are several common methods for storing steel coils in warehouses, depending on the size and weight of the coils, as well as the available space and resources in the warehouse. Here are some of the most commonly used methods: 1. Block stacking: This method involves stacking the steel coils directly on top of each other, forming a block. The coils are typically aligned in rows and columns, with wood or rubber blocks placed between the layers to provide stability and prevent damage. 2. Racking systems: Racks are often used to store steel coils in warehouses. There are various types of racks, including cantilever racks, coil racks, and structural racks. These racks provide a structured system for organizing and storing the coils, allowing for easy access and efficient use of space. 3. Coil cradles: Coil cradles are a type of storage equipment specifically designed for steel coils. They consist of a series of cradles or saddles that securely hold the coils in place. These cradles can be stacked on top of each other to maximize vertical space utilization. 4. Coil pads: Coil pads are flat platforms made from materials such as wood, rubber, or foam. They are placed on the warehouse floor, and the steel coils are then stacked directly on top of them. Coil pads help to distribute the weight of the coils evenly and protect them from damage caused by contact with the floor. 5. Slit coil storage: Slit coils, which are narrower and lighter than full-size coils, can be stored using specialized storage systems. These systems often consist of racks or shelves equipped with dividers or separators to keep the coils organized and prevent them from unraveling. It is important to note that regardless of the storage method used, safety precautions should be followed when handling and storing steel coils in warehouses. This includes ensuring proper weight distribution, using appropriate lifting equipment, and adhering to industry-specific guidelines and regulations.

- Q:i need this for school and i need to know what are some advantages of stainless steel.

- 313 times as resistant to rust and corrosion as mild steel. 30% stronger and more durable than mild steel. 15% more conductive than mild steel. Easily wiped clean. Scratches can be easily polished out.

- Q:How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they provide a reliable and strong structural material. These coils are shaped and formed into various components, such as beams and girders, which are then assembled to create the bridge's framework. The steel coils' durability and high tensile strength make them ideal for supporting heavy loads and withstanding the forces experienced by bridges.

- Q:How do steel coils compare to other materials, such as aluminum or copper?

- Steel coils have several advantages over other materials like aluminum or copper. Firstly, steel is generally stronger and more durable, making it suitable for heavy-duty applications. Steel coils also have a higher melting point, which means they can withstand higher temperatures without losing their structural integrity. Additionally, steel is typically more cost-effective and widely available compared to aluminum or copper. However, it's important to note that the choice between these materials depends on the specific requirements of the application, as aluminum and copper may offer advantages in certain scenarios such as electrical conductivity or weight reduction.

- Q:What are the different types of steel coil storage racks?

- There are several different types of steel coil storage racks, including coil cradles, coil saddles, coil racks, and coil c-hooks. Each type is designed to securely hold and store steel coils of various sizes and weights, providing easy access and efficient storage solutions for industrial facilities.

- Q:I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold rolled steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords