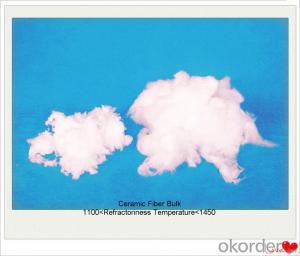

GOOD QUALITY AND BEST PRICE CERAMIC FIBER COTTON BULK

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber bulk is produced by melting the very pure raw materials in high temperature, take use of spun or blowing method with characteristics of stable chemical performance, resistance to most of the erosion of the chemicals. The physical property like refractory and insulation keep same when meet with oil,water or steam. Ceramic fiber blanket/felt/board/paper/cloth/rope and other ceramic fiber products can be produced by bulk through further processing. Ceramic fiber bulk is a kind of insulating materials which has these characteristics,such as light-weight,antioxidation,low thermal conductivity,softness,anti-corrosion,low heat capacity,sound insulation and so on.

Applications

•Filling sealing and insulation at high temperatures(kiln car,pipeline,kiln door,etc.)

•Composite material in fiber industry(friction plate,etc.)

•Expansion joint filler material for firebricks and castable.

•Filler for short time insulation.

•Thermal insulation filing material for samll corner.

•Raw materials for further processing.

Technical Index

Ceramic fiber bulk | HR1050 | HR1260 | HR1350 | HR1430 | HR1600 | |

Classification Temperature(℃) | 1050 | 1260 | 1350 | 1430 | 1600 | |

Melting Point(℃) | 1750 | 1750 | 1750 | 1750 | - | |

Fiber Average Diameter(um) | 2.6 | 2.6 | 2.5 | 2.5 | 1.95 | |

Density(g/m3) | 2.70 | 2.70 | 2.70 | 2.70 | 3.10 | |

Chemical Composition(%) | Al2O3 | 42-45 | 46-49 | 52-55 | 44-48 | 72 |

Al2O3+SiO2 | 97.0 | 97.0 | 97.0 | 82 | 99 | |

Zr O3 | - | - | - | 15-17 | - | |

Other | 3.0 | 3.0 | 3.0 | 2.0 | 1.0 | |

All the fibers are packed in sack with the packing weight 20kg,or made according to the requirements of customers. | ||||||

Note: The result is average value not guarantee value,fluctuate within the standard value, for more details about our products properties or technical support,please contact our Technical Department.

FAQ

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q:Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Name: Cotton aluminosilicate ceramic fiber cotton, is an almost pure inorganic fiber, formed by blowing process production process or thrown silk spray, is a kind of low thermal conductivity, low heat capacity; high strength, high tear resistance, excellent machining performance. Aluminum silicate insulation material has become the best industrial furnace lining wall insulation materials, completely replace refractory bricks.

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q:Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q:What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q:Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q:Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q:What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GOOD QUALITY AND BEST PRICE CERAMIC FIBER COTTON BULK

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords