SPU Waterproof Coating Material Single Component

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

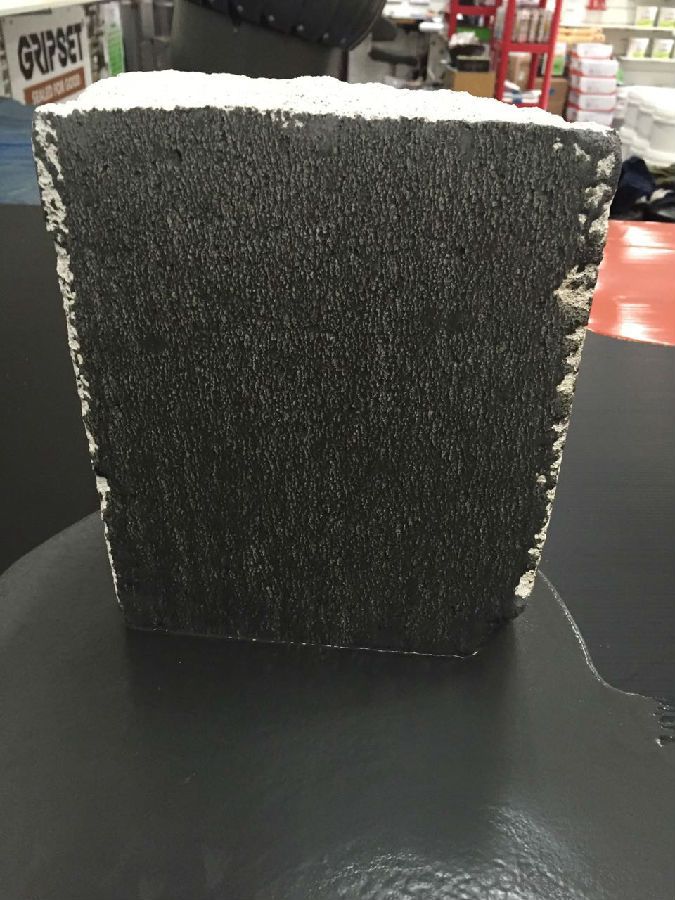

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:What is the car waterproof sticker material?

- B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q:Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Third, according to personal experience, SBS membrane waterproof, as long as the quality of waterproof membrane clearance, and in accordance with the requirements of the strict implementation of the implementation, it can be said that the most assured and a roof waterproofing method. Remember: First, the material to cross the border (must be the real polyester carcass), and second, pay attention to the operation carefully in the construction. Just remember these two points, it will not appear too much problem.

- Q:Roof leakage, what materials do the best waterproof

- hird, for some of the city building cover the construction of red tiles leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package. To strengthen the leak-proof effect, you can also shop a layer of waterproofing membrane. Note: Before the waterproofing and draining construction, the roof must be dry, because the roof of the water does not evaporate, the new waterproof layer will rise, the waterproof effect immediately invalid.

- Q:Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q:What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q:What is the difference between finished mortar and cement mortar?

- Finished mortar white lime compounds, and cement mortar dark gray black.

- Q:What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q:Js waterproof coating without powder can brushing

- 3. Construction: brush with a brush or brush directly to the JS waterproof coating on the base surface, the intensity of the use of uniform, can not leak; if used for moisture, just brush a layer; for waterproof, To three layers. When the first layer of JS waterproof coating dry to just sticky hands (usually 1-2 hours), you can brush the second layer, every two layers of brushing direction should be straight to the intersection;

- Q:How to do waterproof bathroom, construction process is what

- Second, the construction process: 1, grass-roots treatment: grass-roots surface must be smooth and smooth, there must be no pit phenomenon may not loose, trachoma or hole exists. If the above phenomenon should be smooth and smooth after the construction, the surface must be dry, there must be a pipe at the root of the head must be wiped into a circular arc, the pipe must be strong. 2, brushing the primary treatment agent, the "Liang wall" waterproof primer at the end of uniform mixing, and then use a long brush or rubber brush scraper, scratching the waterproof material, even brush to the grass-roots level, brushing Can not be stacked and exposed white bottom, brushing the amount of each time to 0.4kg / square meters is appropriate, the first time after the full dry before brushing the second time. 点击图标下载 App

- Q:What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SPU Waterproof Coating Material Single Component

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords