Black Treadmill PVC Conveyor Belt Black Walking Belt Fitness belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black Treadmill PVC Conveyor Belt Black Walking Belt Fitness belt

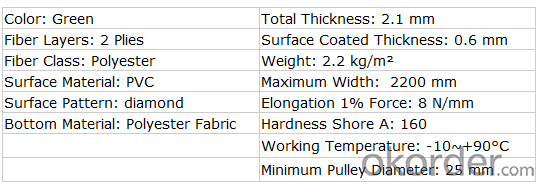

Features of treadmill belt

thickness:1.4 1.6 1.8 2.0 2.3 2.5 3.1 4.3 4.5 mm

household treadmill: 1.8 2.0 2.3mm

gym treadmill:2.5 3.1 4.3 4.5mm

surface: diamond

color: black blue red grey

Know your treadmill belt

A damaged or worn out belt can be dangerous for you and can quickly wear out electrical components of the treadmill.It is better to replace the belt than to risk an injury or more costly repair.

If your belt is running slow, or feels loose, you may assume that the belt needs to be replaced. Often, though, these are indicators of too tight or too loose tension rollers, and can be fixed by either tightening or loosening the tension rollers.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product photos:

Pls contact me freely if any inquiry,thank you!

- Q:Can olive nets be used for both small and large-scale olive tree pollination?

- No, olive nets are typically used for protecting the olives from birds and pests, not for pollination.

- Q:New plastic products have a strong taste, how to remove?

- Substitution method: some inferior plastic products tend to have a heavy odor, and can choose more secure plastic products, such as pure plastic made of resin materials, and less residual monomers. Or substitute materials such as ceramics, glass, wood, etc..

- Q:Can olive nets be used in olive groves with varying tree heights?

- Yes, olive nets can be used in olive groves with varying tree heights. These nets are designed to be flexible and adjustable, allowing them to accommodate trees of different heights. They can be easily installed and adjusted to ensure proper coverage and protection for the olive trees, regardless of their height variations.

- Q:Is it harmful to health to drink water with plastic cups?

- Some transparent soybean milk machine material is PC material, may contain bisphenol A, some soybean milk machine can still cook, release quantity is quite big. Therefore, it is recommended to use stainless steel soybean milk machine. As for plastic boxes, chopsticks, spoons and other products, generally do not contain bisphenol A. A layer of paint can also be used in the inner layer of metal cans, and bisphenol A is also used. Therefore, the metal cans can not be heated directly. They should be eaten at room temperature or poured out of the tin.

- Q:How does an olive net affect the tree health and growth?

- An olive net can have both positive and negative impacts on the health and growth of an olive tree. On one hand, the net provides protection from birds and other animals that may feed on the olives, reducing crop losses and potential damage. This can promote better fruit production and overall tree health. On the other hand, the net can limit airflow and sunlight penetration, potentially leading to increased humidity and reduced photosynthesis. These factors can negatively impact the tree's growth and make it more susceptible to diseases. Therefore, proper management and periodic removal of the olive net are crucial to maintain a balance between protection and the tree's overall health and growth.

- Q:Can olive nets be used for olive trees in regions with frequent storms?

- Yes, olive nets can be used for olive trees in regions with frequent storms. Olive nets are designed to protect the olive fruits from birds and other pests, but they can also provide some level of protection against storms by reducing wind damage and preventing branches from breaking under the weight of water or hail. However, it is important to note that olive nets are not specifically designed as storm protection, so their effectiveness may vary depending on the severity of the storms. Additional measures like staking or bracing the trees may be necessary in areas prone to strong and frequent storms.

- Q:Do olive nets protect against sunburn on olive fruits?

- No, olive nets do not protect against sunburn on olive fruits.

- Q:Are there any specific regulations or guidelines for using olive nets?

- Yes, there are specific regulations and guidelines for using olive nets. These regulations may vary depending on the country or region, but generally, they focus on ensuring the proper installation, maintenance, and removal of nets to minimize potential harm to olive trees and the environment. Guidelines may include using nets made of materials that do not damage the trees, ensuring proper tension to avoid entanglement of wildlife, and adhering to specific timeframes for net installation and removal to prevent damage to the trees. It is essential for olive growers to familiarize themselves with the specific regulations and guidelines applicable to their location to ensure responsible and sustainable olive net usage.

- Q:Do olive nets affect the sunlight exposure of the olive trees?

- Yes, olive nets can affect the sunlight exposure of the olive trees. These nets are designed to provide shade and protect the trees from excessive sunlight, reducing the risk of sunburn and heat stress. However, the extent of sunlight reduction depends on the density and color of the nets used. While they can limit direct sunlight exposure, it's important to strike a balance to ensure sufficient light for photosynthesis and tree growth.

- Q:What are the hazards of plastic oiler

- Need to see what kind of plastic to fill the oil, at room temperature, PET plastic pot of oil is non-toxic, but other plastics in the oil will generally precipitate some chemicals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Treadmill PVC Conveyor Belt Black Walking Belt Fitness belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords