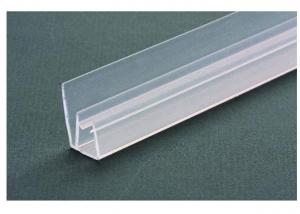

Auto Rubber Fittings Dustproof Cover Sheath

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Auto Rubber Fittings Dustproof Cover Sheath

Lead-time: 7-10days

ISO9001 & TS16949 factory

Qualified supplier of Panasonic/BYD

WSR's mold workshop Description of Auto Rubber Fittings Dustproof Cover Sheath

1. WSR have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Auto Rubber Fittings Dustproof Cover Sheath

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time of Auto Rubber Fittings Dustproof Cover Sheath

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q:Where is the rubber gasket in the door handle of the K3?

- The best is two times of infusion, and should not go together, because cephalosporins itself after dissolving the stability is relatively poor, so in preparation is made of powder, now equipped with, after the dissolution is immediately placed infusion, the longer the stability and drug decomposition rate is high.

- Q:What are the factors that cause the aging of automobile rubber parts?

- Material fatigue caused by alternating hot and cold. Rubber parts in summer should withstand sixty or seventy degrees of high temperature, and may fall below freezing point in winter. The change of temperature will also cause aging of rubber parts.

- Q:The car tire two what is the difference? Which one is better? 1) glue inside; 2) prick holes and glue bars into it

- Fill out the nails, with pliers pull, with the hole and triangular circle, the bar glue folded into a tire with tire cone, pull out the tire rubber tire rubber cone, due to shrinkage is fixed on the sidewall in.

- Q:What kind of material should be used for the sealing ring of diesel fuel filter, what specific requirements should be made?

- Oil resistant rubber with low coefficient of thermal deformationHigh machining accuracy, good surface finishFor example, currently the best Duffett filter sealing ring, all imported from Japan

- Q:The rubber sleeve of the lower triangular support arm of the car is a little active. What harm does it continue to drive?.

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q:What material is the rubber hose on the tank truck?

- The tanker can be used: carbon steel, stainless steel, plastic, glass, steel lining plastic cans (PP), following to tank tanker common material to share.

- Q:How do I fix the car wiper strips?

- In order to wiper longer service life, it is best to avoid a long time in the sun, another point to note is that many owners have found that dust on the glass, often only open the wiper sweep away sand in trouble, it can damage the wiper strip and auto glass, so in the open before May the first spray a little cleaning liquid. Of course, manual cleaning is better.

- Q:What's the black inside of the car seal?

- That is called semi dry sealant, also known as liquid sealant

- Q:The role of particle glue on automobiles

- Automobile particle glue generally used for chassis and the left and right threshold, in fact, chassis armor.

- Q:What's the use of a black rubber tube under the engine of a moped?

- The exhaust pipe has an air vent and the engine exhaust is drawn out.Exhaust pipe structureHose; plastic support screw; pipe wall with fiber coating; spiral wire: special spiral plastic.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Auto Rubber Fittings Dustproof Cover Sheath

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords