angle bar high frequency induction heating equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: Other

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM Group

Model Number: GGP600-0.2-H

Voltage: 1300A

Current: 450V

Weight: 2t-3t

Usage: angle bar welding

Certification: ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Frequency: 150~ 200 kHz

Efficiency: more than 85%

Pipe: 200x200mm~300x300mm

Thickness: 6.0~12.0mm

Welding: induction welding or contact welding

Speed: Induction welding ≥15m/min Contact welding ≥18m/min

color: make as customer requirement

cooling way: water water or air water

Maintenance: easy & low cost

Board: self made

Packaging & Delivery

| Packaging Details: | 1.Standard export wooden package. 2.Fumigated seaworthy wooden boxes 3.Upper/lower back angles for lifting 4.Mark as customer's requirement 5.Follow customer's packing standard 6.20GP or 40GP container (for reference) |

|---|---|

| Delivery Detail: | 20 days |

Specifications

ISO9001

High efficiency & power saving

China famous brand

Full digital control system

HMI and fault diagnosis system

angle bar high frequency induction heating equipment

1.Range of application

Steel pipe welding, Iron pipe welding, stainless pipe welding, aluminium tube welding, copper tube welding, H-beam welding and special pipe welding.

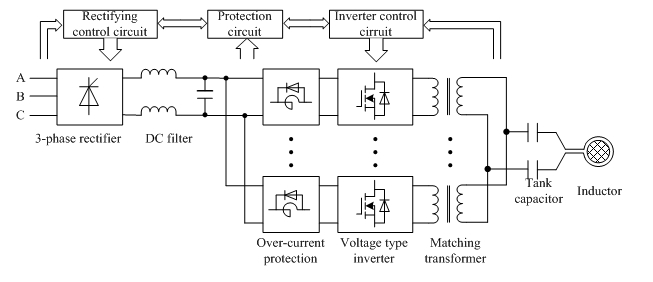

2.Functional structure

The solid state high frequency equipment mainly used for HF welded steel pipe line, it is a typical AC-DC-AC variable frequency structure. Rectifier adopts 3-phase bridge style thyristor phase-control rectifier circuit, DC side adopts inductor, capacitor to compose LC filter which meet the working requirements of voltage type inverter. The voltage type inverter adopts modularization parallel structure to extend power supply power, each inverter module is single phase MOSFET bridge style circuit connected with series resonance tank circuit by H.F. matching transformer. On one hand, the matching transformer realizes power combination and impedance matching; on the other hand it realizes electric isolation of load and power supply. To put effective and swift protection on over-current malfunction of voltage type inverter, our company introduces special and stable over-current protection circuit which guarantees safe and stable running of inverter.

The whole set of solid state H.F. welder comprises of switchgear rectifying cabinet, inverter output cabinet, connecting optical fiber, circulation soft water cooling system, central operator console, mechanical adjustment device, contact welding pole plate and contact pin (contact welding) and etc

3.Circuit structure of Square tube HF induction heating welding machine

4.Equipment composing

The whole set of solid state H.F. welder comprises of switchgear rectifying cabinet, inverter output cabinet, connecting optical fiber, circulation soft water cooling system, central operator console, mechanical adjustment device, contact welding pole plate and contact pin (contact welding) and etc.

5.Brief introduction for Square tube HF induction heating welding machine

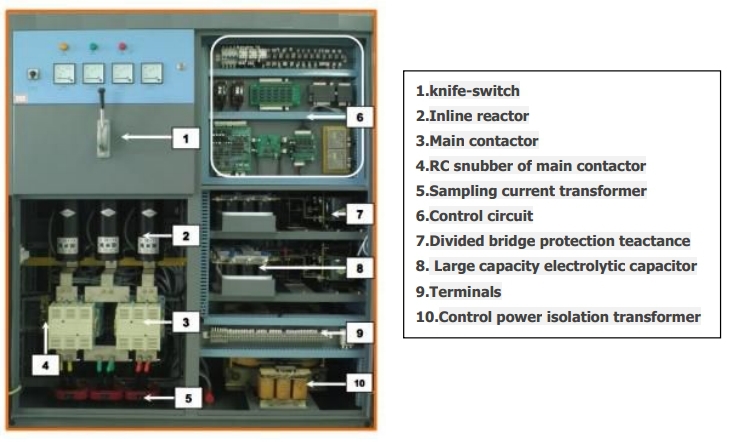

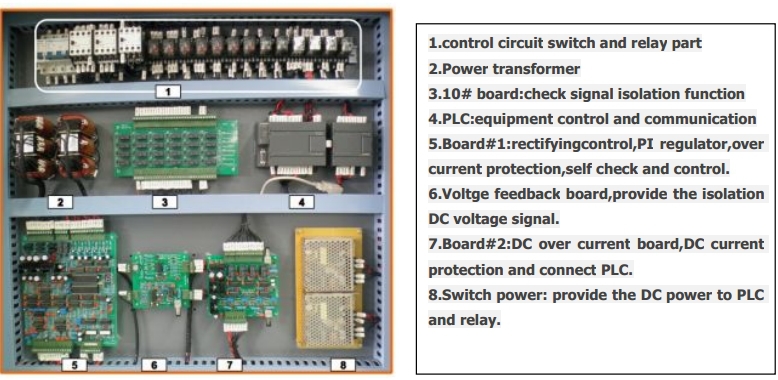

Switchgear rectifying cabinet

Designed with integration of switchgear cabinet and rectifying part, besides achieving switchgear cabinet functions, it also has rectifying control functions of solid state H.F. welders.

Installed line-in switch, line-in current meter, voltage meter (can be switched) and line-in voltage indication lamp.

Installed 3-phase full-controlled thyristor Rectification Bridge to realize power adjustment of the HF welder.

Installed flat-wave reactor, flat-wave capacitor and filter to improve the flat-wave coefficient.

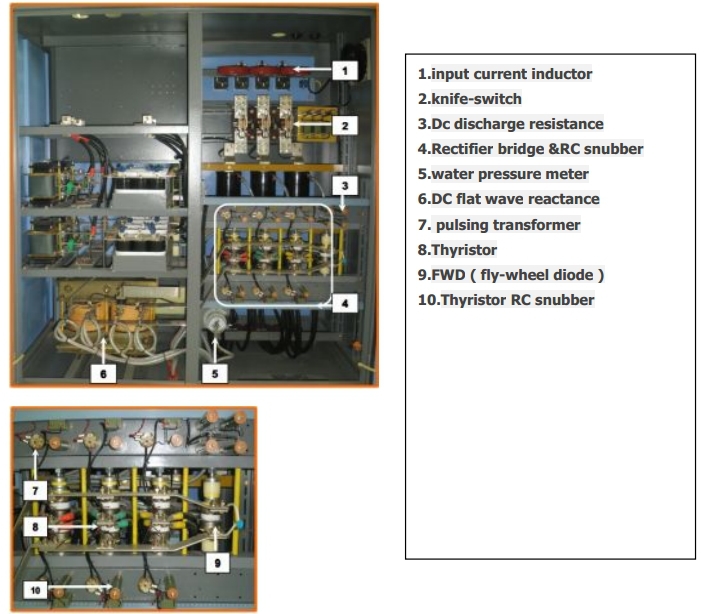

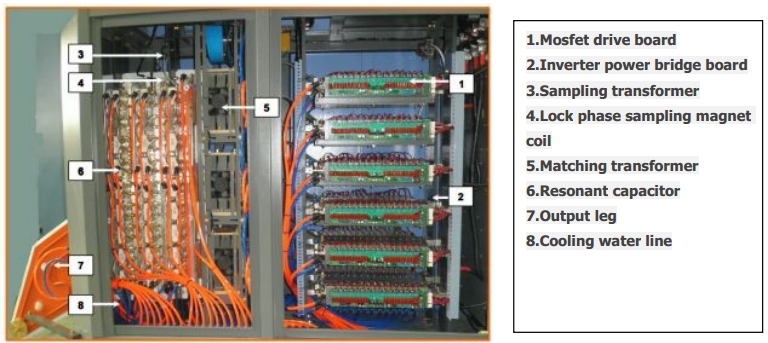

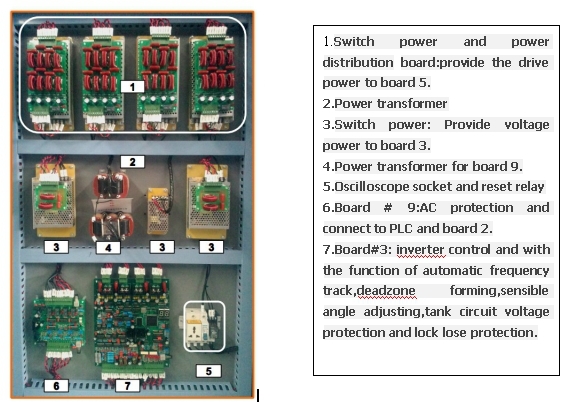

Inverter output cabinet

The inverter part is consisted of MOSFET single-phase inverter bridge connected in parallel. The power of single-phase bridge is 120kW; the inverter bridge adopts the building block method to realize power superposition. Every piece of bridge plates is designed in the shape of a drawer, which is very easy to install and repair.

The matching transformer is adopted for power combination, also it adopts the output method by of secondary resonance and non-welding transformer, tank circuit resonance capacitor (low voltage) resonates with the sensor directly, and the output pole plate offers required power transmission for pipe welding.

Adopted sealed equipment case, installed with air conditioner.

Circulation soft water cooling system

circulation soft water is used as cooling water with temperature and water level indicator and protection.

Central operation console

It realizes solid state H.F. welder remote operation and power regulation, installed with LCD which indicates armature voltage, field voltage indication and of DC drive and DC voltage, DC current indication of H.F. welders.

Mechanical adjustment device

Applied to install inverter output cabinet and adjust inductor position. 2D and 3D adjustable.

- Q:What should be paid attention to when welding the air conditioner copper pipe welding machine?

- 1. Prepare the welding equipment and the necessary fittings and air conditioning copper tubes.2, be sure to clean the parts to be welded and air conditioning copper pipe, so as to ensure the correct solder joints.3, will want to cut the air conditioning copper tube to do the corresponding mark, use copper cutter to cut air conditioning copper tube.4, with both ends of cloth or gauze cleaning air conditioning pipe, until it looks clean. This is done to remove dirt and grease and prevent oxidation.

- Q:What is the welding machine for glass fibre reinforced plastic cable protection tube?

- The glass fiber reinforced plastic material joint is only suitable for bonding and riveting. It can not be welded, so there is no special welding machine.

- Q:Which brand is the best for plastic pipe welding machine? How to ensure the quality of PE pipe welding machine?

- Domestic plastic pipe welding machine has a welding magic card do well, the price of foreign brands is too far off, and so it is used

- Q:How to weld the air conditioner copper tube welding?

- How can the air conditioning copper tube and copper pipe be welded?Copper tube and copper tube welding is generally used silver electrode (its silver content is 25%, 15% or 5%) or copper and phosphorus series welding rod, they all have good fluidity, do not need welding flux. Specific welding procedures are as follows:1) welding copper tube processing: expansion and deburring, old copper pipe must also use abrasive paper to remove oxide layer and dirt. When the diameter of the welded copper pipe is different greatly, it is necessary to clamp the pipe with big diameter in order to ensure that the gap between welds should not be too large.2) nitrogen filling: the copper pipe is filled with nitrogen to carry out welding, which can make the inner wall of copper tube bright, clean and oxide free, so as to effectively control the cleanliness of the system.3) open the welding torch, adjust the mixture ratio of oxygen and acetylene, and choose neutral flame.4) first heated by the flame tube insertion, slightly hot after the flame moves outward a little casing, heating the pipe when the pipe joint uniformly heated to the welding temperature (micro solder (red), adding silver electrode or phosphorus brazing). By the solder melting temperature, and flame temperature maintaining outer flame pipe joints, and not using pre solder melt drip welding joints, then heating welding, otherwise it will affect the strength and density of joints.5) remove the flame and close the torch. Check the quality of the weld. If there is a gap or a sand heel in the weld, re weld the weld

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

angle bar high frequency induction heating equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords