Aluminum Square Ceiling Tiles For Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling) Description

mineral wool acoustic board is a kind of highgrade indoor decorative material, mainly used as suspension ceiling. Taking mineral wool as its main material together with some additive, it is made through mixing, molding, drying, cutting, carving, surface finishing, and spraying procedures. It is widely used in indoor decoration industry especially for first-class buildings, such as hotels, restaurants, stadiums office buildings, shopping centers, studios, computer rooms, airports, railway stations, factories, hospitals, home and other public buildings.

With a good sound-absorbing character, it can effectively control and regulate indoor reverberation time, improve tome quality and lower noise. It has damp-proof and rot-proof characters, also has a good incombustibility so could meet the fire-proof demand of many buildings. Different sizes and patterns of boards displaying various art styles are available in our company to give the decorative effect of different and artistic styles.

2,Main Features of the (Mineral Fiber Ceiling)

(1)Normal size: 300x600mm, 300 x 1200mm,600x600mm, 600x1200mm etc.

Customer’s requirements are available

(2)Thickness: 8-20mm

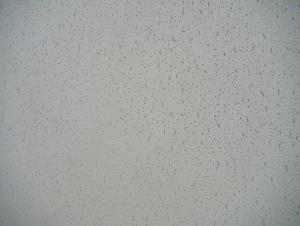

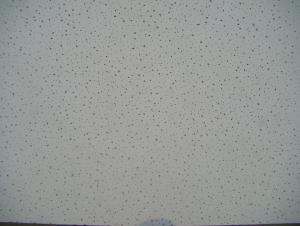

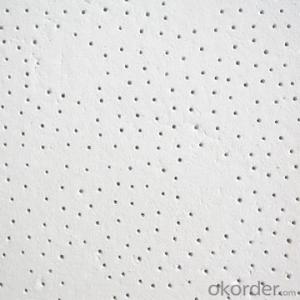

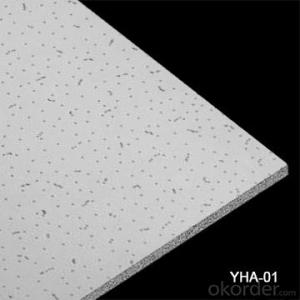

(3)Type: 1). little-stars series flowers 2). Lovely-worms series flowers 3). Convex-sprinklin series 4 ). Different shape boards

Price term: FOB or CIF

Payment term: TT/LC

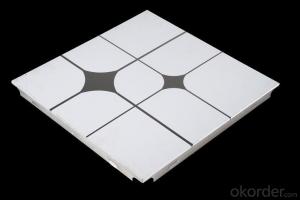

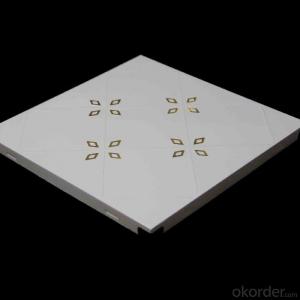

3,(Mineral Fiber Ceiling) Images

4,(Mineral Fiber Ceiling) Specification

Physical properties of mineral fiber ceiling tiles

Properties | Data | |

Density | Low density | 280-320 kg/m3 |

Hight dentisty | 390-420 Kg/m3 | |

Thickness | Low density | 12-20 mm |

Hight dentisty | 6.5-20 mm | |

Fire rating | Low density | Class B1 |

Length*Width | 300*600 , 595*595 , 603*603 , 595*1195 , 603*1212 mm | |

Product content | Mineral fiber | |

Fiber content | ≥90% | |

Surface finish | Applied Vinyl latex paint | |

Color of surface | White | |

Edge | Square edge, Tegular edge | |

NRC | 0.40-0.50 | |

Thermal conductivity | ≤0.065w/mk | |

Light reflection | ≥85% | |

Sagging resistant Properties | Warranty against visible sag | |

Humidity resistance | Resistance to 90% relative humidity | |

5,FAQ of (Mineral Fiber Ceiling)

Lead Time: within 15-20 days after receipt of the T/T deposit or L/C.

Packing: plastic paper

Loading port: XINGANG, china

Origin:Hebei, China

We could also supply the relevant Channel (Light steel keel), Include two parts: Accessories System for Ceiling and

Accessories System for Wall Partition, about the detail you could check our other product: Light Steel Keel.

With a good sound-absorbing character, it can effectively control and regulate indoor reverberation time,

improve tome quality and lower noise. It has damp-proof and rot-proof characters, also has a good incombustibility

so could meet the fire-proof demand of many buildings. Different sizes and patterns of boards displaying

various art styles are available in our company to give the decorative effect of different and artistic styles.

- Q:Crystal furniture crystal trim is not really true

- It is fake, it is artificial, it is not true

- Q:Example: gypsum decorative plate specifications for the 500 * 500mm, the patchwork width of 2mm, the loss rate of 2%, calculated 10m2 need to use gypsum plate number. Solution: gypsum decoration

- To determine the length and width of the area to know the need for a few gypsum board.

- Q:What are the functions of inorganic pre-coated decorative panels?

- Inorganic precoat decorative panels in the international community refers to the inorganic non-combustible material as the substrate, the surface of a special process with a decorative coating, the final form can be directly installed without the use of surface treatment of decorative plates. Inorganic precoat decorative board of the substrate requirements are higher, requiring the material itself is better strength, impact resistance, bending, bending, fire, light, water absorption, acid, alkali, thermal expansion coefficient, temperature difference The Inorganic precoat decorative panels are mainly coated with fluorocarbon coating, inorganic ceramic coating, polyurethane coating. Fluorocarbon coating because of its fluorine molecular characteristics, so that its surface with excellent performance, weather resistance, acid, alkali, scrub resistance and other properties are excellent performance, and its rich color, glossy, Is unmatched by other materials. The inorganic ceramic coating in the main performance and fluorocarbon coating equivalent in the surface hardness is higher than the general coating, is mainly in foreign production, domestic only individual manufacturers can produce similar homogeneous plate. Polyurethane coating in all respects with fluorocarbon coating, inorganic ceramic coating has a certain gap, mainly for interior decoration.

- Q:Cheetah cs6 bumper trim plate

- Hello, generally on the Internet, Auto Parts City and 4S shop are sold, if my answer to your help, please set as the best answer, thank you for your hands!

- Q:304 stainless steel decorative panels and 201 stainless steel decorative board how long anti-rust time

- Look at the use of the environment the worst of the seaside next to the industrial area and the riverside followed by the city next to the countryside. There are indoor and outdoor differences, can not be specific answer time.

- Q:Farm small courtyard of the kang kang skirt with what decorative plate good

- To ask the decorative board which is strong Jin Ke Ma * metal exterior decorative decorative panels easy to install labor hours, the price of preferential policies, large amount of money, moisture and drought, fire and flame retardant security, life comparable to days

- Q:Conventional decorative panels, decorative plate construction process is to paste the glue to the grass-roots board or fixed with a nail in the grass-roots board, I would like to ask this process "glue method, nail"

- Wood products generally have the characteristics of dry shrinkage expansion, intimate operation as carefully as possible! Base board fixed decorative panels are completely with glue without the practice of nails, but generally or glue nail, so more solid, If it is finished finishes, the surface can not have nails, generally using the back pendant fixed method.

- Q:Accord 9 left door door trim how to split ah?

- First find the front switch handle behind a lid, with the weapon to pry it open, the inside of the screw unloaded and then down the armrest also has a lid, the same reason to remove the screw, then look at the right side of the glass edge there is a small Triangle plaque, hand off the edge can be directly removed, no screws, the next step to take a small knife inserted into the door under the edge of the gap, pry open a certain gap with the fingers after the force to break apart, the veneer around Buckle are out, up the trim plate can come up with a little, and then press the door switch handle, so that with the veneer separation, and then pull out the control plug can be.

- Q:Ceiling the last piece of decorative plate

- Good size! Plus 0.5-1CM length slightly shorter ~ ~ rebate!

- Q:What is the general thickness of the wall water decoration board?

- Cement pressure plate common specifications for the 1220mm × 2440mm × 2.5-100mm, or 1200mm × 2400mm × 2.5-100mm. According to the density can be divided into low density, medium density, high density category. Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. Is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing a new building materials. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Square Ceiling Tiles For Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords