Aluminium Circle for Cooking Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Circle for Cooking Applications Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Circle for Cooking Applications:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

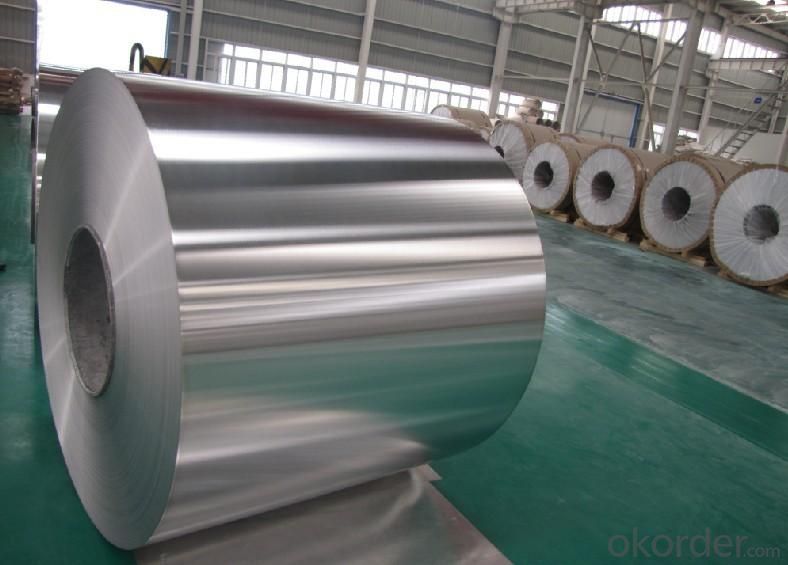

Images of the Aluminium Circle for Cooking Applications:

Aluminium Circle for Cooking Applications Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Circle for Cooking Applications:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Are the aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant.

- Q:What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets can vary depending on the specific alloy and thickness. Generally, it ranges between 20,000 to 45,000 pounds per square inch (PSI).

- Q:What are the common thicknesses of aluminum sheets used in transportation industry?

- The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.032 inches to 0.125 inches.

- Q:My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- Coating your existing aluminum windows will help absolutely zero. To be effective, you would need a thermal break between the aluminum and the heated portion of your house. Unless you have aluminum storms applied directly to aluminum windows, you should already have some kind of thermal break. At the end of the day, the aluminum is not really costing you much in terms of energy loss. Adding any kind of coating to the storms does not help because it is not between the aluminum and your heated area. I can't think of a way you could do this anyway. Aluminum is incredibly hard to get a coating to stick to and I have never seen a product that would be suitable for this.

- Q:Are the aluminum sheets suitable for manufacturing electrical busbars?

- Yes, aluminum sheets are suitable for manufacturing electrical busbars. Aluminum is a popular choice for busbars due to its excellent electrical conductivity and lightweight properties. It can efficiently conduct high electrical currents and has low resistance, making it ideal for conducting electricity in power distribution systems. Additionally, aluminum sheets can be easily fabricated and formed into various shapes and sizes, allowing for customization and efficient installation in electrical systems.

- Q:How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q:What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding. 1. Adhesive bonding: This method involves using an adhesive to bond two aluminum sheets together. The adhesive creates a strong and durable bond, and it can be applied in various ways such as tapes, liquid adhesives, or films. Adhesive bonding is a popular choice as it provides a clean and aesthetically pleasing finish. 2. Mechanical fastening: This method involves using mechanical fasteners such as screws, rivets, or bolts to join aluminum sheets together. These fasteners provide a strong and reliable connection and are commonly used in industries where disassembly or repair is required. Mechanical fastening is also relatively easy to implement and does not require any additional equipment. 3. Clinching: Clinching is a cold-forming process that involves joining aluminum sheets by using a punch and die to create a strong interlock between them. This method is suitable for thin aluminum sheets and offers good mechanical strength. Clinching is a cost-effective alternative to welding, as it does not require any additional materials or heat. 4. Friction stir welding: Although not technically welding, friction stir welding is a solid-state joining process that uses a rotating tool to generate frictional heat between the aluminum sheets. As the tool moves along the joint, it creates a plasticized region that is then consolidated to form a strong bond. Friction stir welding is mainly used for joining thicker aluminum sheets and offers excellent mechanical properties. 5. Folded joints: This method involves folding the edges of two aluminum sheets together to create a joint. The folded joint can be secured by using adhesives, mechanical fasteners, or a combination of both. Folded joints provide good strength and stiffness, and they are commonly used in applications where a seamless appearance is desired. These methods offer various advantages and can be chosen based on the specific requirements of the project, including the desired strength, appearance, and ease of implementation.

- Q:Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- According to the general arrangement from low to high prices:The first 1 lines are the cheapest, such as 1050.1060.1070..1100, which is pure aluminum;Second, 3 Department prices, such as 3003.3004.3104, etc.. Among them, 3003 for aluminum manganese alloy, the lowest price in the 3 series, and then 3004.3104, for aluminum, magnesium, manganese alloy than 3003 price to be slightly higherThird bit, 5 series, i.e. aluminum magnesium alloy, such as 5005.50525083. 5005 of these prices are slightly lowerThen, the ---2 system and --4 system and --7 system of the 6 series are derived

- Q:I get to do an aluminum blank for a fence and I am curious whether I can put slots in it with the router?I am not sure how thick it is, may say 3/16's.

- Yes you can use a router on aluminium. Use some kind of a fence, a piece of angle iron or a block of hardwood. Use a new bit, an old dull one will cause you problems. Pre-drill smaller holes than the slot width at each end of the slot. Stay back away from the end of the slot about 1/32 of an inch. Make several passes, at a depth of about 1/16 of an inch, per pass. If you can, make the slot with a bit smaller than the finished slot width. Use a 3/16 bit for a 1/4 inch slot. Use a 5/16 bit for a 3/8 inch slot. This will give cleaner slot edges and allow you to accurately make the slot width that you want. You can do this dry, but a little WD-40 oil will give even cleaner slot edges. Also climb mill the last pass on each slot edge to give a better/ smother edge. Climb Milling is pushing the router backwards of the way you normally travel in wood. Ben

- Q:With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- Use aluminum rivets

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Circle for Cooking Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords