AA1100 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1100 Prepainted Aluminium Coils Used for Construction Description

AA1100 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1100 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1100 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

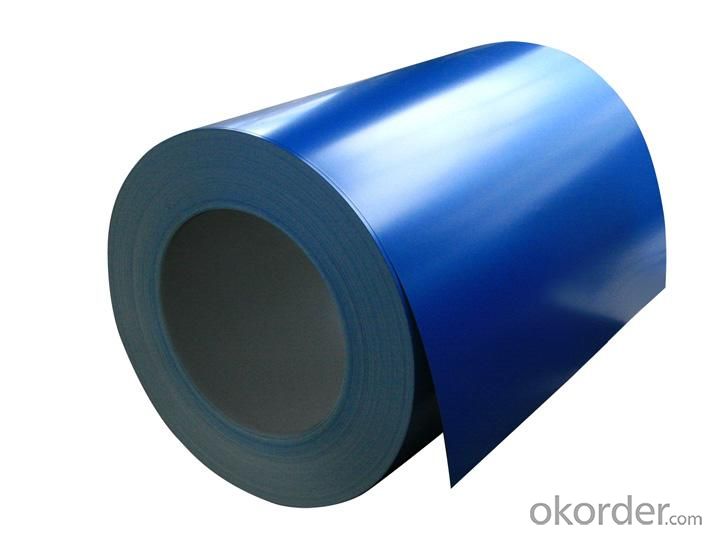

3.AA1100 Prepainted Aluminium Coils Used for Construction Images

4.AA1100 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1100 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum coils be used in kitchen appliances?

- Kitchen appliances can indeed utilize aluminum coils. Due to its remarkable thermal conductivity and resistance to corrosion, aluminum is extensively employed in the production of kitchen appliances. It finds frequent application in refrigerators, air conditioners, and other devices that necessitate efficient heat transfer. Lightweight and enduring, aluminum coils effectively disperse heat, rendering them ideal for a wide array of kitchen appliances.

- Q:Can aluminum coils be used for industrial piping?

- Industrial piping can indeed utilize aluminum coils. Aluminum, being a versatile and lightweight material, presents numerous advantages for industrial piping purposes. Its exceptional resistance to corrosion makes it a suitable choice across various industries such as chemical, petrochemical, and food processing. Moreover, aluminum coils are effortlessly manageable and can be molded into diverse configurations and dimensions, providing flexibility when designing and installing piping systems. Furthermore, aluminum's commendable thermal conductivity proves advantageous for applications that necessitate heat transfer. Nevertheless, it is crucial to carefully contemplate the specific requirements of the industrial process and seek advice from professionals to guarantee that aluminum coils are appropriate for the intended application.

- Q:What is the typical electrical resistivity of aluminum coils?

- Aluminum coils have an average electrical resistivity of around 2.65 x 10^-8 ohm-meters, showcasing their exceptional conductivity. This attribute renders them a top-notch option for electrical conductors. The remarkable conductivity enables an efficient flow of electric current within the coils, thereby reducing energy dissipation and heat production. Consequently, aluminum coils find extensive utilization in diverse electrical sectors, including transformers, motors, and generators.

- Q:Are there any certifications or standards for aluminum coils?

- Certifications and standards exist for aluminum coils, ensuring their quality and performance. The Aluminum Association's Certification Program is widely recognized as the most prominent certification for aluminum coils. This program guarantees that the coils meet the specific standards and requirements established by the association. Moreover, multiple organizations such as ASTM International, ASME, and ISO have set various standards and specifications governing the manufacturing and performance of aluminum coils. These standards encompass crucial aspects like the coils' chemical composition, mechanical properties, and dimensional tolerances, guaranteeing compliance with industry requirements.

- Q:What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q:Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes. Aluminum is a non-magnetic material, meaning it does not have any magnetic properties. In order to use coils for magnetic purposes, materials with magnetic properties such as iron or steel are commonly used. These materials can generate and conduct magnetic fields, whereas aluminum cannot.

- Q:How are aluminum coils protected against corrosion?

- Various methods are utilized to protect aluminum coils from corrosion. One prevalent approach involves applying a protective coating or finish to the coil's surface. This coating acts as a barrier, preventing the aluminum surface from coming into contact with moisture, oxygen, and other potentially corrosive elements present in the surroundings. The coating can take the form of a layer of paint, anodizing, or a specialized protective film. Another technique employed to safeguard aluminum coils from corrosion is alloying. By incorporating small quantities of other metals such as copper or zinc into the aluminum, the corrosion resistance of the alloy is enhanced. These alloyed metals create a protective oxide layer on the aluminum's surface, serving as a shield against corrosion. In addition to coatings and alloying, proper cleaning and maintenance of aluminum coils are essential for corrosion prevention. Regular cleaning helps eliminate any contaminants or corrosive substances that may have accumulated on the coil's surface. This ensures the integrity and effectiveness of the protective coatings or oxide layers in preventing corrosion. Furthermore, the proper installation and sealing of aluminum coils are imperative for corrosion protection. Effective sealing prevents moisture or other corrosive agents from infiltrating the interior of the coil, which can result in corrosion over time. Overall, a combination of protective coatings, alloying, regular cleaning, and proper installation techniques plays a crucial role in safeguarding aluminum coils against corrosion. This ensures their durability and optimal performance.

- Q:How do aluminum coils contribute to energy efficiency?

- Aluminum coils contribute to energy efficiency by improving the heat transfer efficiency in various applications. The high thermal conductivity of aluminum allows for better heat exchange, resulting in reduced energy consumption and increased overall efficiency of cooling and heating systems. Additionally, aluminum coils are lightweight and durable, making them more efficient to manufacture, transport, and install, thus reducing energy requirements throughout their lifecycle.

- Q:Are aluminum coils suitable for high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and can deform or degrade at elevated temperatures.

- Q:When aluminum metal is heated with an element from group VIA of the periodic table, an ionic compound forms. When the experiment is performed with an unknown croup VIA element, the product is 18.56% Al by mass. What is the formula of the compound and what is its name?

- Al2Se3 aluminum selenide

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1100 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords